Multifunctional pre-melted slag refining agent for steelmaking and preparation method of multifunctional pre-melted slag refining agent

A technology of pre-melting slag and refining agent, applied in the field of multi-functional steel-making pre-melting slag refining agent and its preparation, can solve the problems of poor electrical conductivity and weak oxygen ion migration force, shorten the refining time, The effect of widening activity and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

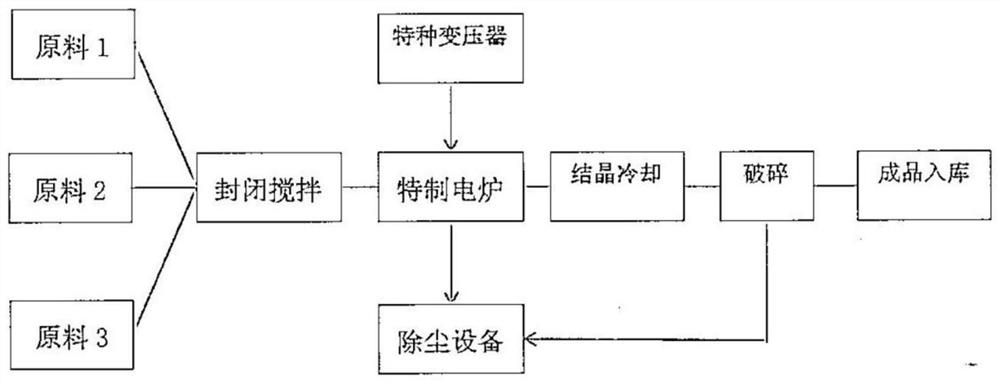

Method used

Image

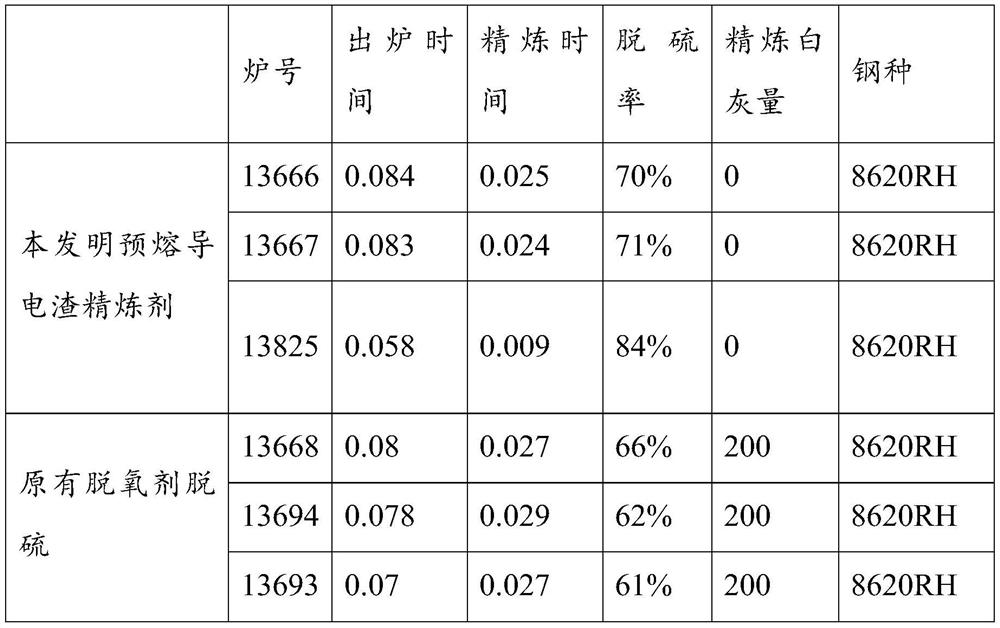

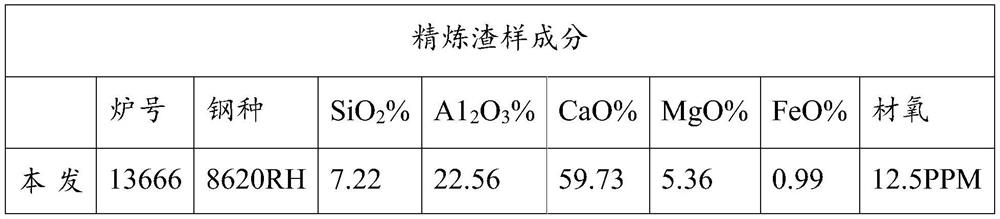

Examples

Embodiment 1

[0025] This embodiment provides a multifunctional pre-slag refining agent for steelmaking. The raw materials for preparing the multifunctional pre-slag refining agent for steelmaking include materials rich in alumina, materials rich in oxide locks and materials rich in calcium oxide .

[0026] Preferably, the alumina-rich material is aluminum ash / aluminum slag produced in the electrolytic aluminum production process: the calcium oxide-rich material is calcium carbide slag, quicklime powder, white mud for papermaking, calcium powder, lime dust , any one or more of waste calcareous ash.

Embodiment 2

[0028] This embodiment provides a multifunctional pre-slag refining agent for steelmaking. The raw materials for preparing the pre-slag refining agent include the following components calculated in parts by weight: SiO 2 3 parts, CaO 9.5 parts, A1 2 o 3 1 part, MgO 1.0 part, CaF 2 1 serving.

Embodiment 3

[0030] This embodiment provides a multifunctional pre-slag refining agent for steelmaking. The raw materials for preparing the pre-slag refining agent include the following components calculated in parts by weight: SiO 2 63 parts, 44 parts of CaO, A1 2 o 3 50 parts, MgO 5.0 parts, CaF 2 5 servings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com