Cavity interconnection based deposition method and deposition equipment

A deposition equipment, cavity technology, applied in gaseous chemical plating, metal material coating process, coating and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

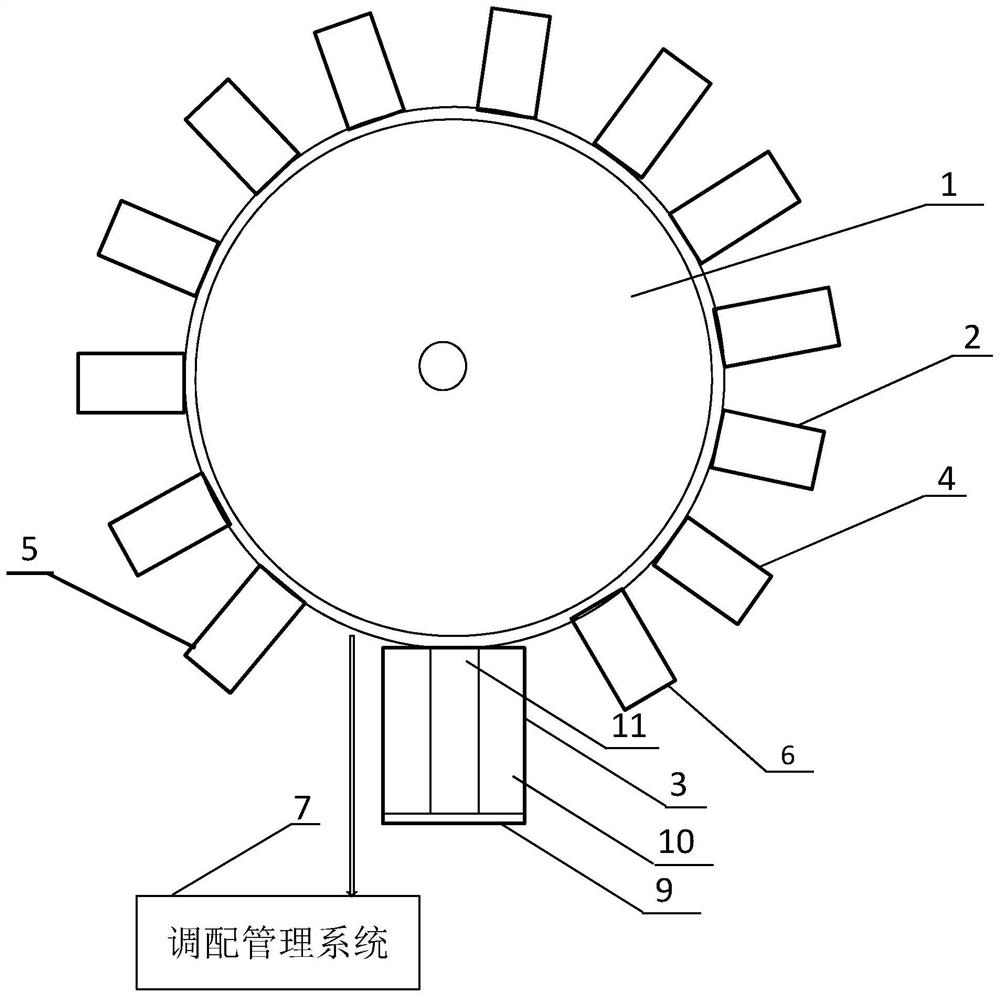

[0051] see figure 1 , the present invention provides a technical solution: a deposition device based on chamber interconnection, which adopts ALD technology, and includes a vacuum distribution platform (1), at least two reaction chamber groups (2), a loading chamber (3), At least one thermal atomic layer deposition chamber (4), at least one pre-cleaning chamber (5), at least one thermal treatment chamber (6) and a deployment manager (7);

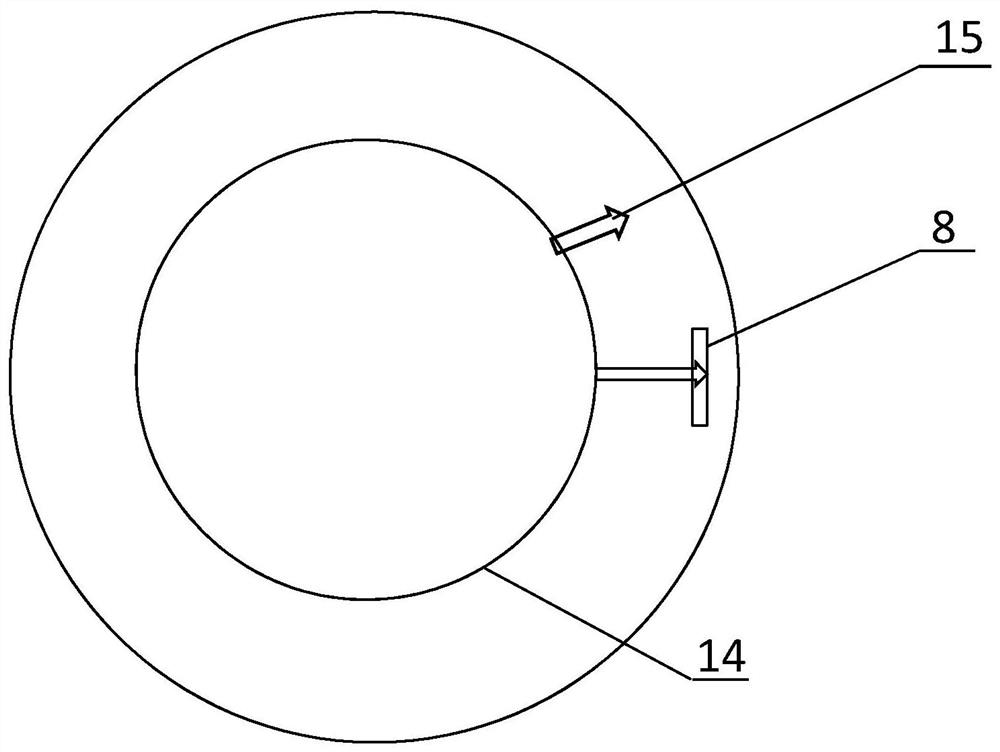

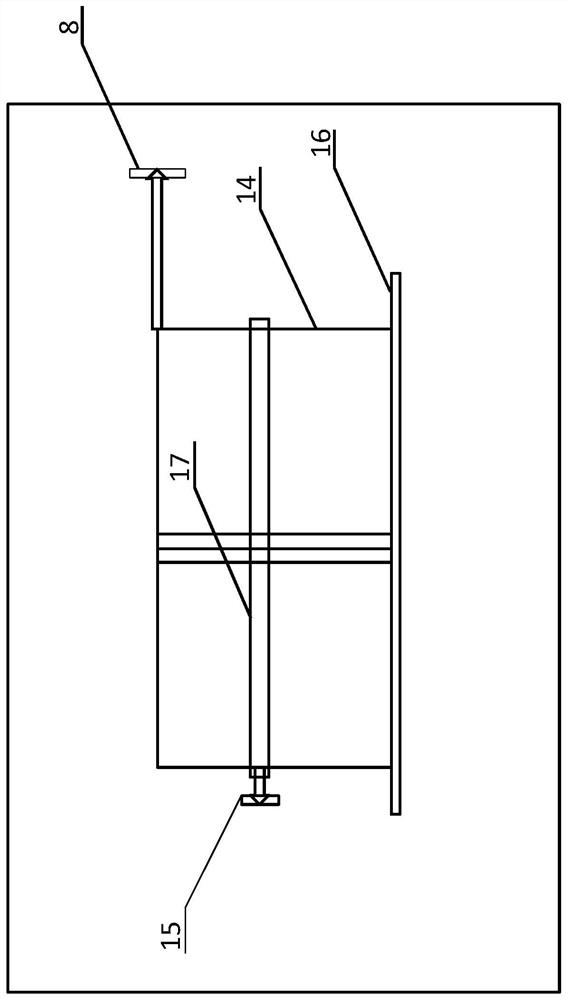

[0052] Wherein; the reaction chamber group (2), loading chamber (3), thermal atomic layer deposition chamber (4) pre-cleaning chamber (5) and heat treatment chamber (6) to surround the vacuum distribution platform ( 1) arrangement; the vacuum distribution platform (1) maintains a vacuum and dust-free environment, including an automatic delivery robot (8), and the automatic delivery robot (8) is connected to the deployment manager (7) for data communication, The automatic conveying robot (8) is used in the reaction chamber group (2), the loa...

specific Embodiment 2

[0066] On the other hand, the present application also provides a deposition method based on cavity interconnection, including deposition equipment based on cavity interconnection, and the specific wafer processing method is as follows;

[0067] Step S1, rationally configure the number of reaction chamber group 2, loading chamber 3, thermal atomic layer deposition chamber 4, pre-cleaning chamber 5 and heat treatment chamber 6 according to the current process, assemble them, and debug the vacuum configuration Platform 1, reaction chamber group 2, loading chamber 3, thermal atomic layer deposition chamber 4, pre-cleaning chamber 5, heat treatment chamber 6 and deployment manager 7, so that the deposition equipment based on chamber interconnection works normally ;

[0068] Step S2, adding the wafer base material into the deposition equipment based on cavity interconnection, and the deposition equipment based on cavity interconnection starts the wafer process work;

[0069] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com