Super-amphiphobic fabric and preparation method thereof

A super-amphiphobic fabric technology, applied in textiles and papermaking, liquid repellent fibers, fiber processing, etc., can solve the problems of cumbersome preparation process, poor stability and low buoyancy of super-amphiphobic fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] A first aspect of the present invention provides a method for preparing a super-amphiphobic fabric, comprising the steps of:

[0020] S1 mixing ethanol and deionized water, and adjusting the pH to 8-11 to obtain the first solution;

[0021] S2 Add dopamine hydrochloride, aminosilane and fluorosilane to the first solution, and mix uniformly to obtain the second solution;

[0022] S3 Soak the fabric in the second solution, stir and react for 20-60 hours, take it out and dry it to obtain the super-amphiphobic fabric.

[0023] In the present invention, polydopamine (PDA) can be obtained by autoxidative polymerization of dopamine hydrochloride, fluorosilane is connected with aminosilane through hydrolysis reaction, and polydopamine and aminosilane undergo a Schiff base reaction to generate in-situ PDA on the surface of cotton fabric with low surface energy. Nanoclusters can finally prepare superamphiphobic cotton fabrics with excellent load-bearing capacity and antifouling ...

Embodiment 1

[0037] A kind of super-amphiphobic fabric, its preparation method comprises the steps:

[0038] (1) Mix 20mL ethanol and 20mL deionized water, and adjust the pH to 9 with 2wt% NaOH solution to obtain the first solution;

[0039] (2) Under stirring, add 60mg of dopamine hydrochloride, 80mg of 3-aminopropyltriethoxysilane, and 80mg of 1H,1H,2H,2H-perfluorodecyltriethoxysilane in turn to the first solution, continue Stir evenly to obtain the second solution;

[0040] (3) Soak the clean cotton fabric that has been ultrasonically washed with ethanol and deionized water for 10 minutes and dried in the second solution, stirred at a speed of 450 rpm for 24 hours, taken out and dried in an oven at 60°C to obtain a super-amphiphobic fabric .

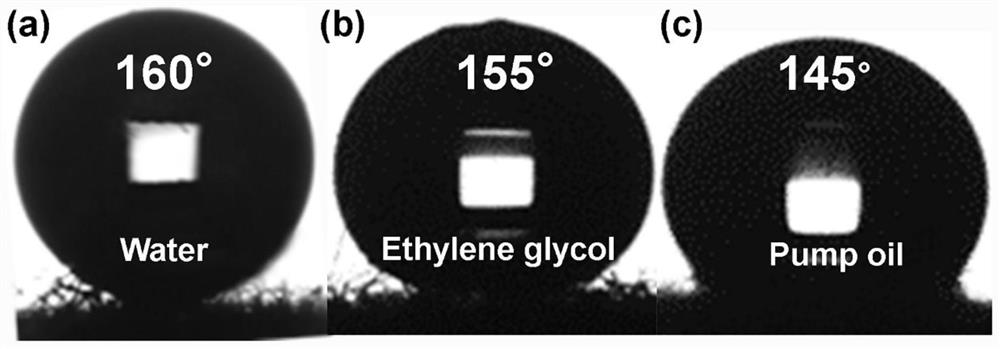

[0041] The contact angles of the modified cotton fabric prepared in this example with water, ethylene glycol, and pump oil were measured to be 154°, 151°, and 124°, respectively, indicating that the modified cotton fabric has superamphiphobic pr...

Embodiment 2

[0043] A kind of super-amphiphobic fabric, its preparation method comprises the steps:

[0044] (1) Mix 20mL ethanol and 20mL deionized water, and adjust the pH to 9 with 2wt% NaOH solution to obtain the first solution;

[0045] (2) Under stirring, add 80mg of dopamine hydrochloride, 80mg of 3-aminopropyltriethoxysilane, 80mg of 1H,1H,2H,2H-perfluorodecyltriethoxysilane in turn to the first solution, continue Stir evenly to obtain the second solution;

[0046](3) Soak the clean cotton fabric that has been ultrasonically washed with ethanol and deionized water for 10 minutes and dried in the second solution, stirred at a speed of 450 rpm for 24 hours, taken out and dried in an oven at 60°C to obtain a super-amphiphobic fabric .

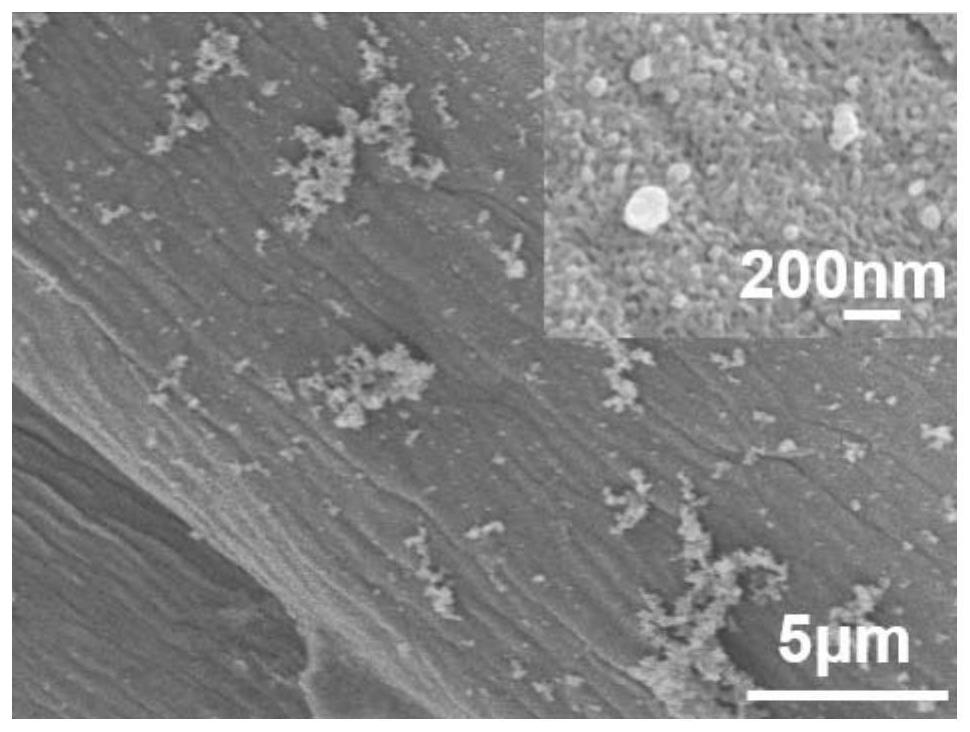

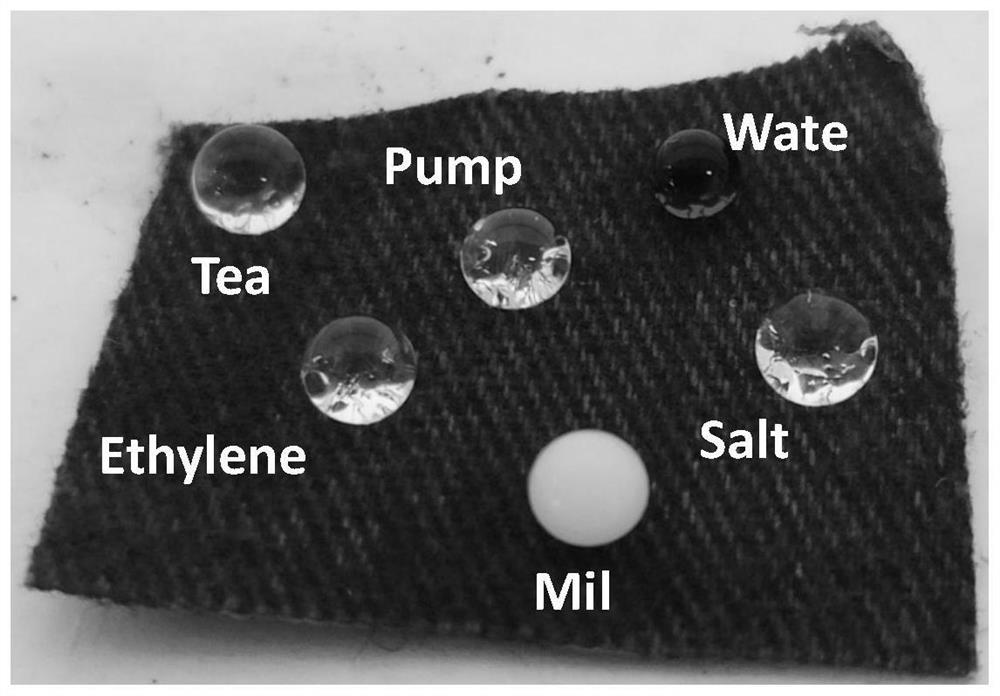

[0047] Measure the SEM picture of the modified cotton fabric prepared by the present embodiment as figure 1 As shown, the contact angle picture is as figure 2 As shown, the contact angles with water, ethylene glycol and pump oil are 160°, 155°, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com