Expanded polystyrene (EPS) worm gear and preparation method thereof

A technology of worm gear and skeleton layer, which is applied in the direction of mechanical equipment, belt/chain/gear, portable lifting device, etc., and can solve the problems of inability to achieve light weight and long molding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

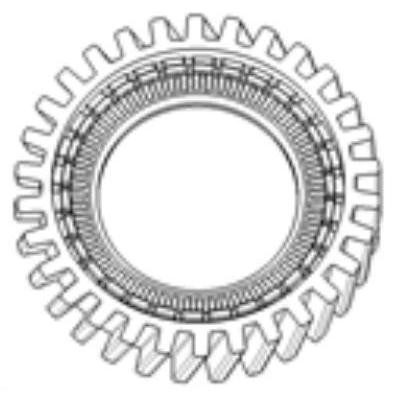

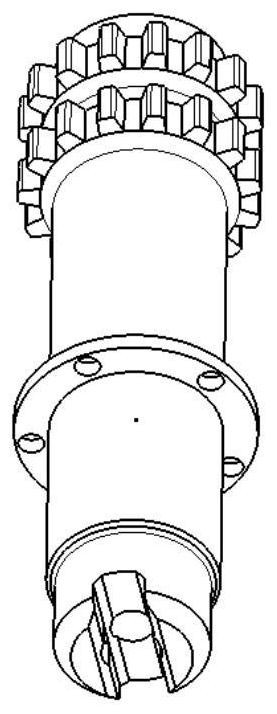

[0052] The present invention provides a kind of preparation method of the EPS worm gear described in the above technical solution, comprising:

[0053] The outer ring of the worm wheel is prepared by reaction injection molding;

[0054] The reinforced material is filled between the outer ring of the worm wheel and the metal shaft for injection molding to form a skeleton layer to obtain the EPS worm wheel.

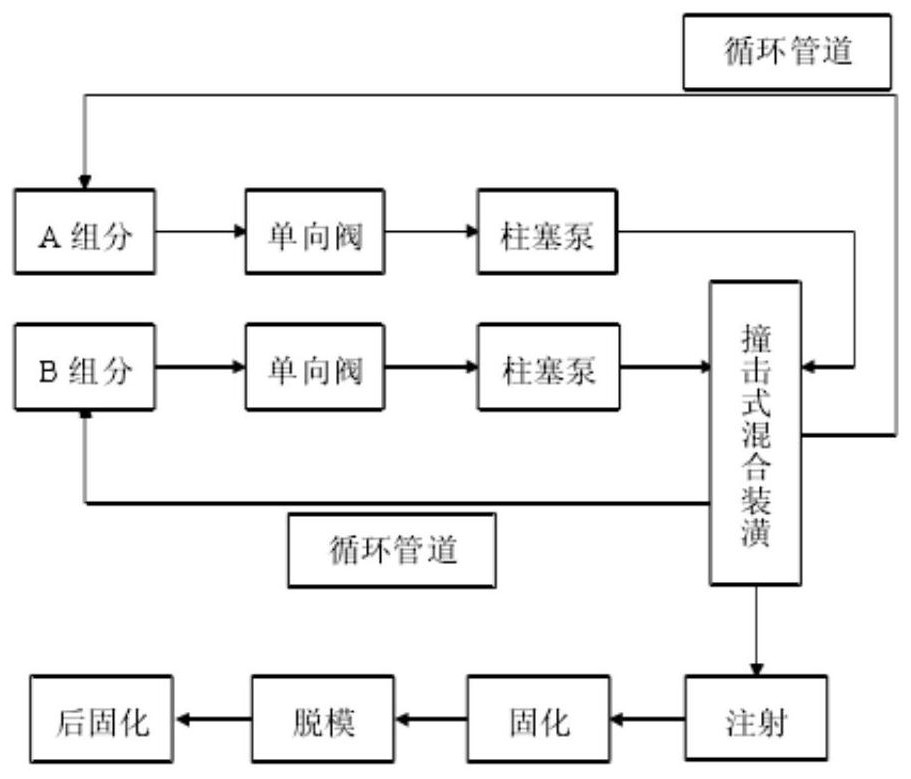

[0055]The present invention has no special limitation on the specific technical process of the reaction injection molding, and the outer ring of the worm wheel can be prepared by using a specific method of reaction injection molding well known to those skilled in the art. The technological process of reaction injection molding in the embodiment of the present invention is as follows figure 1 shown.

[0056] In the present invention, the method of reaction injection molding preferably includes:

[0057] Material A and material B are injected into the mold after high-speed...

Embodiment 1

[0072] The caprolactam of 50 parts by weight, the sodium caprolactam (catalyst) of 0.1 part by weight, the glass fiber (reinforcing material) of 5 parts by weight, the PTFE micropowder (wearing agent) of 15 parts by weight is put into reactor A, 50 parts by weight of Caprolactam, 5 parts by weight of block compound (prepared by polytetramethylene glycol and hexamethylene diisocyanate, number average molecular weight is 12000) is put into reactor B; The material is heated to 120°C, and the moisture in the system is replaced by nitrogen replacement, under nitrogen protection, waiting for reaction injection molding.

[0073] Connect the nozzle of the reaction injection molding machine to the injection port of the EPS worm wheel outer ring mold, and the materials in the reactor A and reactor B are injected into the cavity of the mold after high-speed collision and mixing in the mixing chamber of the reaction injection molding machine, and the mold is kept The temperature is 150°C....

Embodiment 2~7

[0076] The EPS worm wheel was prepared according to the method of Example 1, and the difference from Example 1 was that the preparation was carried out according to the amount of raw materials in Table 1.

[0077] The consumption ratio (parts by weight) of each raw material in the embodiment of table 1

[0078]

[0079]

[0080] Note: Caprolactam and laurolactam in Table 1 are parts by weight of total caprolactam and laurolactam in reactor A and reactor B, and the quality of caprolactam and laurolactam in reactor A and reactor B The ratio is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com