Additive regulation and control method for reducing sinking depth of electric upsetting end face to improve mixed crystals

A technology of electric upsetting and end face, which is applied in the field of plastic forming of metal materials, which can solve the problems of uneven grain distribution at the front end of the billet and large sinking depth, so as to improve quality and performance, reduce sinking depth and reduce sinking depth Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

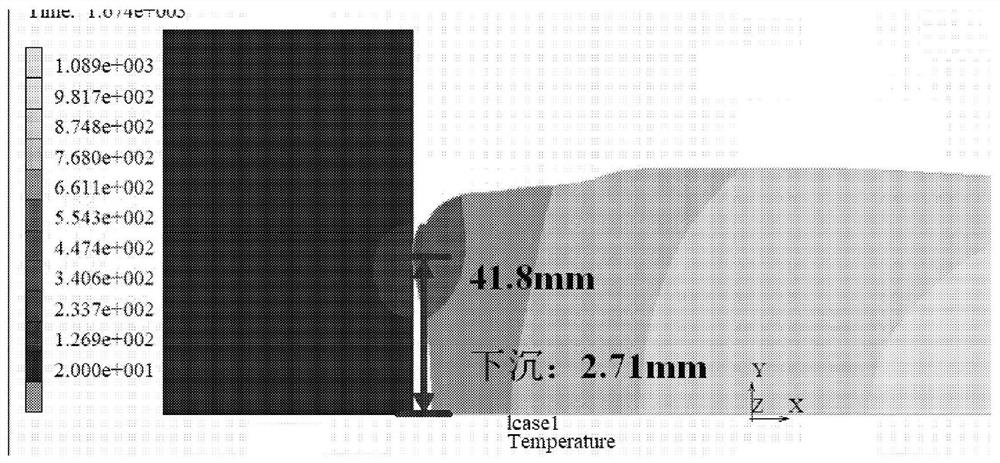

[0032] Reduce the sinking depth of the end surface of the electric upsetting to improve the additive control method of the mixed crystal. The outer ring of the end where the blank and the anvil electrode are in contact is formed by arc additive manufacturing. The diameter D of the blank is 56mm, and the length L is 1500mm, the thickness of the added material is about 0.036D, which is 2mm, and the length is about 0.027L, which is 40mm. After the material is added, the end is rounded. The radius of the rounded corner is 15mm, and then the electric upsetting Forming processing.

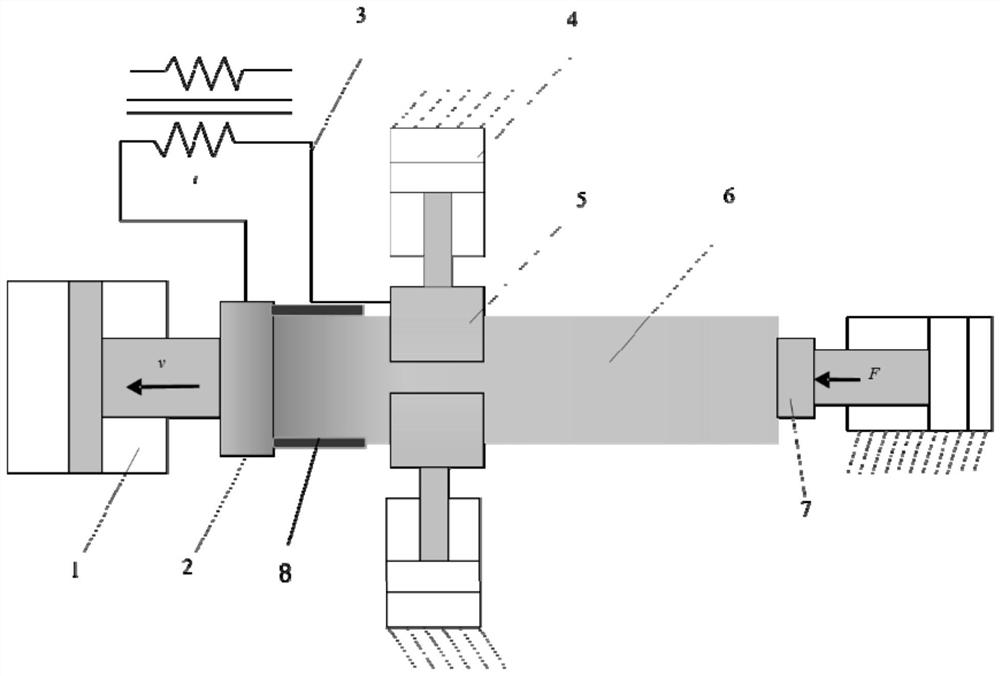

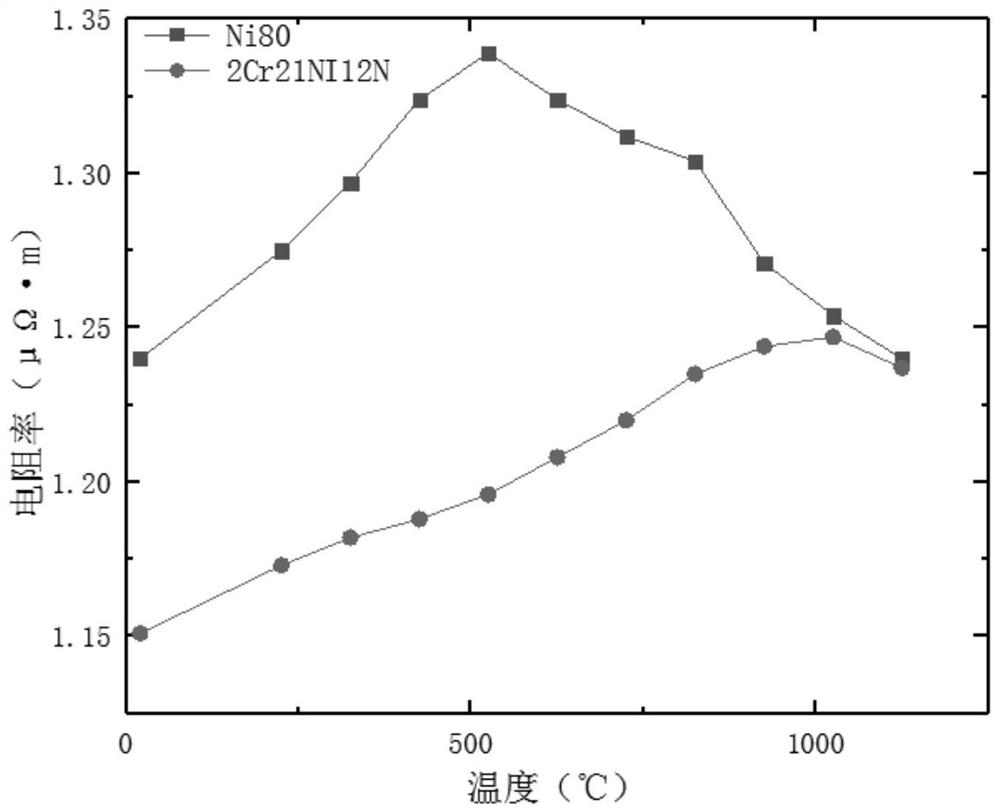

[0033] The principle of electric upsetting is as follows: figure 1 As shown, it includes anvil cylinder 1, anvil electrode 2, secondary transformer 3, clamp cylinder 4, clamp electrode 5, blank 6 and upsetting cylinder anvil 7; during electric upsetting, anvil electrode 2 and clamp The holding electrode 5 is heated by the contact resistance and its own resistance, and the blank 6 and the additive materi...

Embodiment 2

[0038] The difference from Example 1 is that material addition is performed on both the end and the outer ring of the blank, that is, the entire end of the blank is added, and the thickness of the added material is 2 mm.

Embodiment 3

[0040] The difference from Example 2 is that the addition of material at the end of the blank is concentric with the center of the end of the blank, and the diameter d is 20 mm to 56 mm at the ring, and the thickness of the addition is 2 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com