Carbon fiber production method and carbon fiber production equipment capable of realizing one-step demonomerisation and defoaming

A kind of production equipment and technology of carbon fiber, which is applied in the field of carbon fiber production method and equipment field of one-step desingling and degassing, can solve the problems of low production efficiency and poor quality of polymerization liquid, etc. Single-deaeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

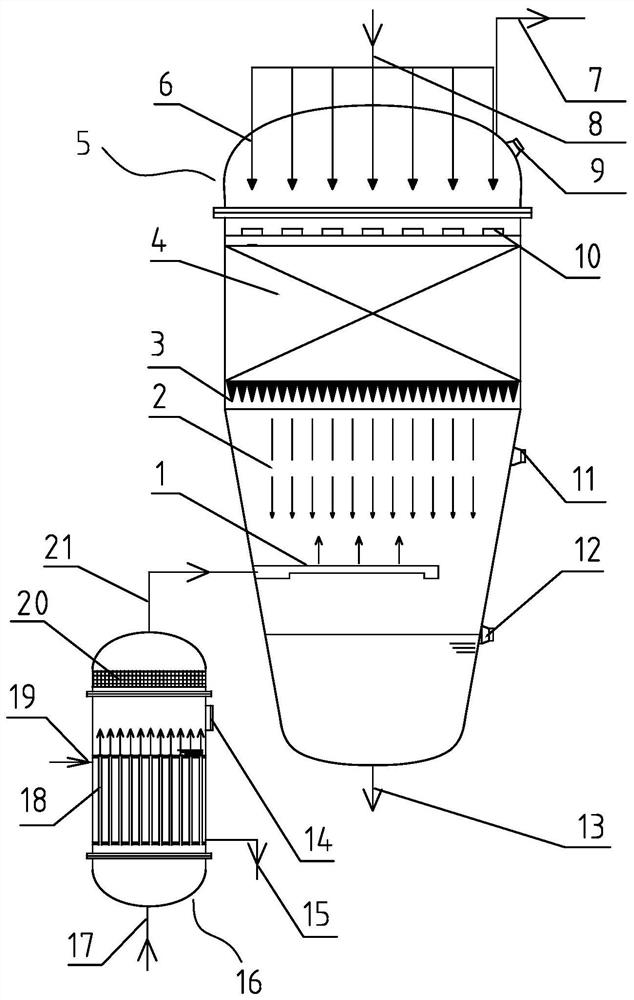

[0035]Such asfigure 1 As shown, a one-step deserted carbon fiber production apparatus includes a reactor 5, a reboiler 16, and a vacuum device, and the vacuum device is connected to the reactor 5 through the vacuum port 7, and the top end of the reactor 5 is provided. The polymer liquid feed pipe 8, the internal feed distribution pipe 6 is provided inside the reactor 5, and the feed distribution tube 6 is connected to the polymer feed pipe 8, and the feed distribution pipe is provided below the feed distribution plate 10, The feed distribution disk 10 is provided with a wire mesh filler 4, and the wire mesh filler 4 is fixed by the stent support, and the wire mesh filler 4 is disposed under the lower circumference 3, and the cone 3 is also fixed. On the bracket. The reactor 5 is provided with a padded DMSO steam dispersing disc 1, and the DMSO steam dispersing disc 1 is located above the liquid portion in the reactor 5 and below the cone 3. Next, a DMSO feed tube 17 is provided belo...

Embodiment 2

[0044]As compared with Example 1, the difference in the present embodiment is that a one-step method of decorating a carbon fiber production method, the specific steps are:

[0045](1) Start the vacuum device to reduce the internal pressure of the reaction kettle 5 until drop to 0.8 kPa;

[0046](2) The polymerization liquid 2 is injected into the feed distribution tube 6 in the reaction kettle 5 by the polymer feed tube 8, and the polymer flow is 3800 kg / hr, the concentration of the monomer is 10%, the polymerization liquid is 12 ~ The 28 feed distribution tube 6 is evenly distributed to the feed distribution tray 10, and from the feed distribution disc 10, the wire mesh filler 4 is passed through the tapered body 3 through the cone 3, and obtains a considerable depreciation- Defoulating massive surface area, and the wire mesh filler 4 is described below, and a fine wire polymerization liquid having a diameter of 0.5 mm to 5 mm is flowed downward; the reaction kettle 5 is provided with...

Embodiment 3

[0051]As compared with Example 1, the difference in the present embodiment is that a one-step method of decorating a carbon fiber production method, the specific steps are:

[0052](1) Start the vacuum device to reduce the internal pressure of the reaction kettle 5 until 5 kPa;

[0053](2) The polymerization liquid 2 is injected into the feed distribution tube 6 in the reaction kettle 5 by the polymer feed tube 8, and the polymer flow is 2300 kg / hr, the concentration of the monomer is 10%, the polymerization liquid is 12 ~ The 28 feed distribution tube 6 is evenly distributed to the feed distribution tray 10, and from the feed distribution disc 10, the wire mesh filler 4 is passed through the tapered body 3 through the cone 3, and obtains a considerable depreciation- Defoulating massive surface area, and the wire mesh filler 4 is described below, and a fine wire polymerization liquid having a diameter of 0.5 mm to 5 mm is flowed downward; the reaction kettle 5 is provided with a top vie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com