High-strength flexible sheath material for anti-nuclear-electromagnetic cable and preparation method of high-strength flexible sheath material

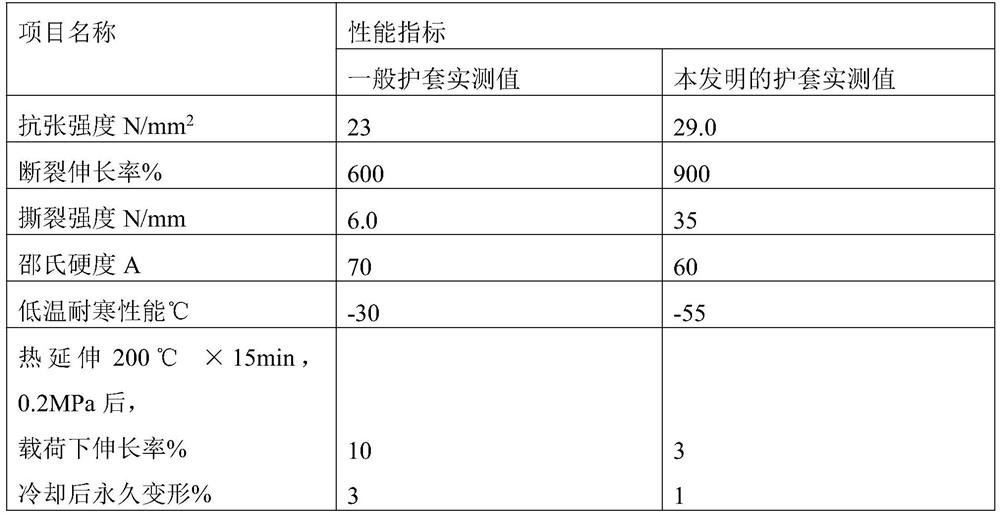

An anti-nuclear electromagnetic, high-strength technology, applied in rubber insulators, organic insulators, etc., can solve the problems affecting the service life of the cable, the cold resistance, softness and tensile strength of the cable jacket, etc., to improve the drag and movement. The effect of retractable and retractable capabilities, increased combat efficiency, increased tensile strength and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The high-strength flexible sheath material for an anti-nuclear electromagnetic cable according to an embodiment of the present invention is made of the following components in parts by weight: 100 parts of CR321 neoprene rubber, 2-3 parts of magnesium oxide, and 3-4 parts of indirect zinc oxide , 2-3 parts of paraffin, 1-2 parts of coumarone resin, 0.5-1.0 part of antioxidant RD, 0.5-1.0 part of vulcanization accelerator DM, 0.5-1.0 part of stearic acid, 0.6-1.5 part of antioxidant DNP parts, anti-scorch agent CTP (PVI) 0.2-0.5 parts, accelerator (NA-22) 0.8-1.5 parts, accelerator TMTD 0.4-0.6 parts, calcium carbonate 5-7 parts, talcum powder 20-25 parts, N330 carbon 15-20 parts of black, 8-10 parts of clay, 5-8 parts of semi-reinforced carbon black, 2-3 parts of rubber oil, 4-6 parts of dioctyl fat, 4-7 parts of cold resistance agent DOS.

[0017] A high-strength flexible sheath material for anti-nuclear electromagnetic cable and a preparation method thereof, character...

Embodiment 2

[0023] The high-strength flexible sheath material for an anti-nuclear electromagnetic cable according to an embodiment of the present invention is made of the following components in parts by weight: 100 parts of CR321 neoprene rubber, 2-3 parts of magnesium oxide, and 3-4 parts of indirect zinc oxide , 2-3 parts of paraffin, 1-2 parts of coumarone resin, 0.5-1.0 part of antioxidant RD, 0.5-1.0 part of vulcanization accelerator DM, 0.5-1.0 part of stearic acid, 0.6-1.5 part of antioxidant DNP parts, anti-scorch agent CTP (PVI) 0.2-0.5 parts, accelerator (NA-22) 0.8-1.5 parts, accelerator TMTD 0.4-0.6 parts, calcium carbonate 5-7 parts, talcum powder 20-25 parts, N330 carbon 15-20 parts of black, 8-10 parts of clay, 5-8 parts of semi-reinforced carbon black, 2-3 parts of rubber oil, 4-6 parts of dioctyl fat, 4-7 parts of cold resistance agent DOS.

[0024] A high-strength flexible sheath material for anti-nuclear electromagnetic cable and a preparation method thereof, character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com