Treatment liquid for on-line cleaning of hygienic product production line and preparation method and application of treatment liquid

A technology for cleaning treatment and sanitary products, applied in the field of cleaning treatment in enterprise production, can solve the problems of inability to take into account decontamination, glue removal, cleaning, economic losses of production enterprises, and many defective products produced, and achieves easy large-scale industrial production. , Easy to operate, strong targeted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific embodiments.

[0022] 1. Components and preparation conditions of the on-line cleaning treatment liquid for the sanitary product production line of the present invention to obtain the cleaning treatment liquid.

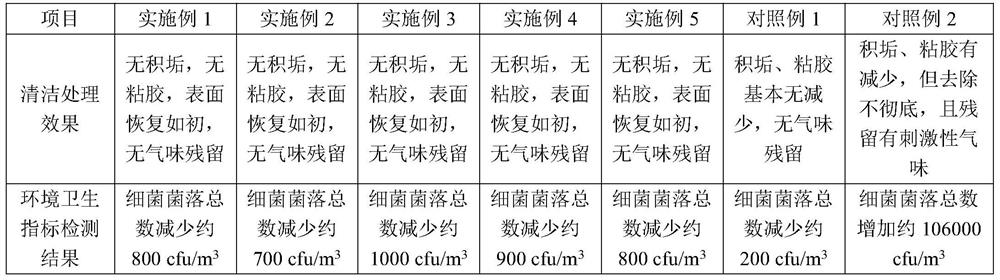

[0023] Table 1 is treatment liquid composition and preparation condition of the present invention

[0024] Ratio of main raw materials Example 1 Example 2 Example 3 Example 4 Example 5 L-glutamic acid-gamma-ethyl ester / g 10 20 30 40 50 L-Aspartic acid-beta-tert-butyl ester / g 25 20 15 10 5 Sodium alginate / g 1 2 3 4 5 Coconut oil fatty acid / g 5 4 3 2 1 Aloe Vera and Cinnamon Leaf Extract / L 1 1 1 1 1 The first ultrasonic stirring time / h 1 1.5 1.5 2 2 The second ultrasonic stirring time / h 1 1 1 0.5 0.5 The third ultrasonic stirring time / h 0.5 0.5 1 1 1

[0025] Table 2 Alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com