Preparation method and application of lithium ion battery positive electrode material

A lithium-ion battery and cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve problems such as poor product stability, uneven coating, complex processes, etc., to achieve good consistency, easy reaction control, The effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

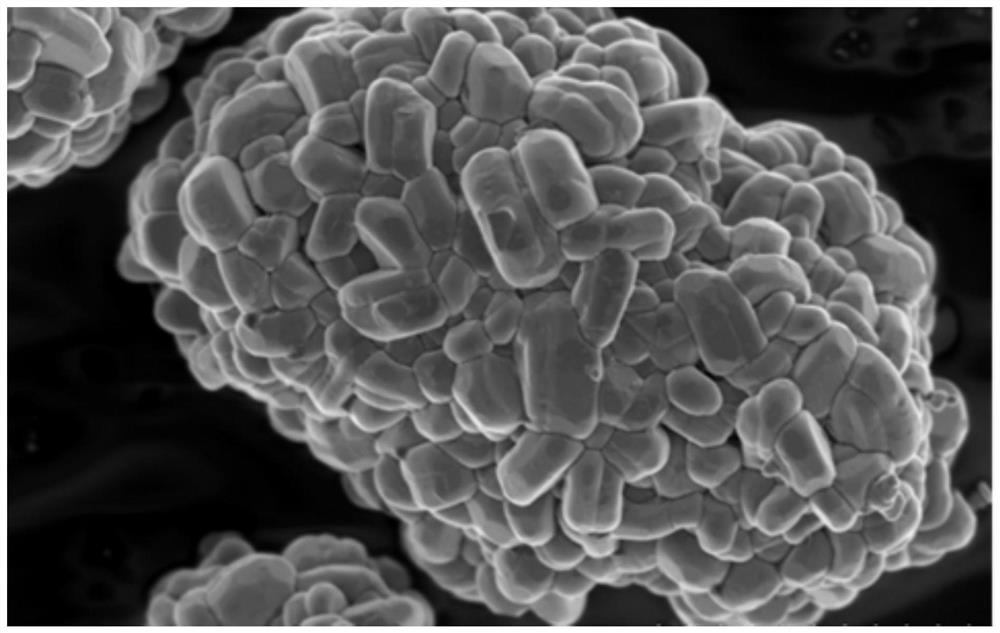

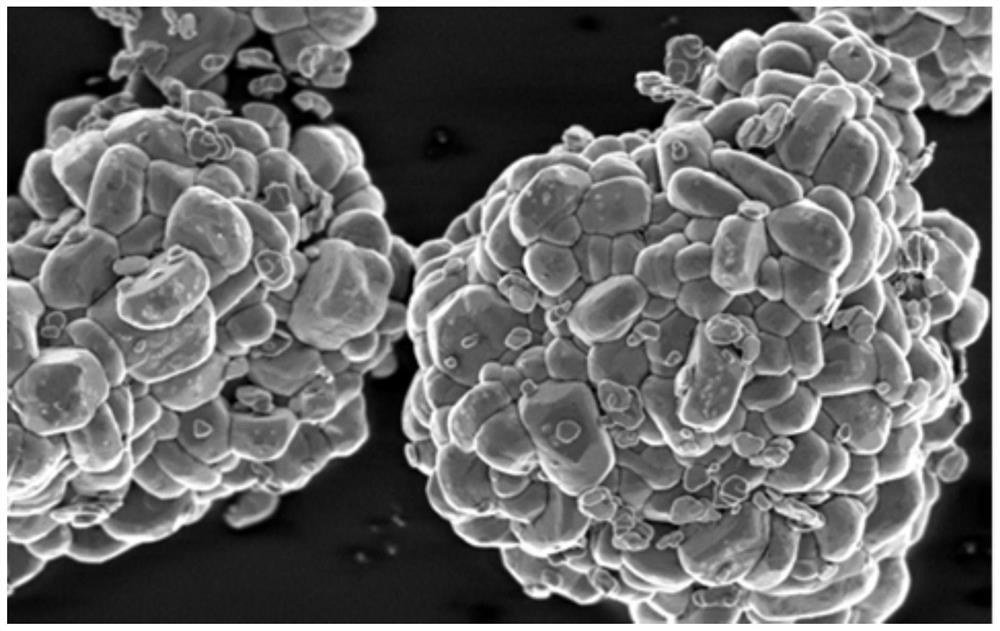

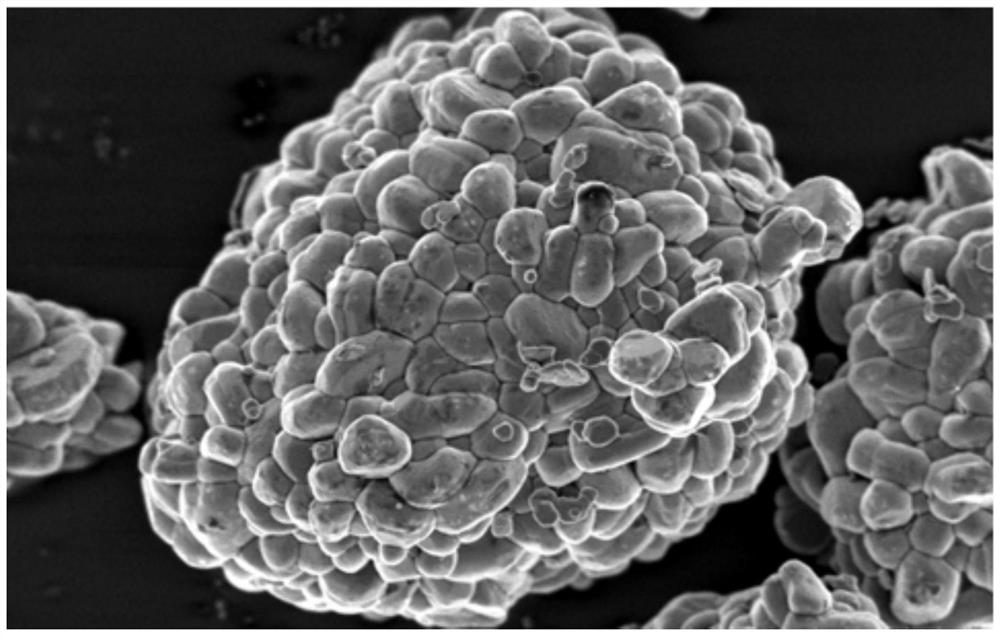

Image

Examples

Embodiment 1

[0045] (1) Add 3.5L of deionized water into a 10L small water bath container with a stirring device, add 3.5kg of substrate while stirring, and keep the temperature of the water bath at 50°C to obtain the first suspension.

[0046] (2) Pass into the conjugate acid-base pair solution in the first suspension, adjust the pH value to 9.5 ± 0.1, obtain the second suspension liquid, wherein the conjugate acid-base pair solution is 150g / L ammonium bicarbonate solution.

[0047] (3) Dissolve 69.5 g of aluminum nitrate nonahydrate in 600 mL of deionized water to prepare an aluminum nitrate solution. Use deionized water to prepare a sufficient amount of 1 mol / L lithium hydroxide solution. The quality of aluminum nitrate (metal salt) can be calculated according to the target aluminum coating amount of 1300ppm, the aluminum content of aluminum salt and the precipitation rate.

[0048] (4) Pass the aluminum nitrate solution and the lithium hydroxide solution in the step (3) to different ...

Embodiment 2

[0053] The pH values in step (2) and step (4) in Example 1 are all changed to 10.5±0.1, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0055] Except following steps, all the other steps are identical with embodiment 1:

[0056] Step (3) is changed to "add 10% dilute sulfuric acid to 600mL deionized water, adjust the pH of the solution<2, and dissolve 25.0g of titanium sulfate in it", and the flow rate of lithium hydroxide solution in step (4) is changed to 10.3mL / min. The mass of titanium sulfate (metal salt) can be calculated according to the target titanium coating amount of 1300ppm, the titanium content of the titanium salt, and the precipitation rate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com