Electrostatic resonator based on periodic elastic wave reflection structure

A reflective structure and resonator technology, applied in electrical components, impedance networks, etc., can solve the problems of small geometric size of devices and limitations of lithography process accuracy, achieve small size, avoid limitations of lithography accuracy, and reduce anchor loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

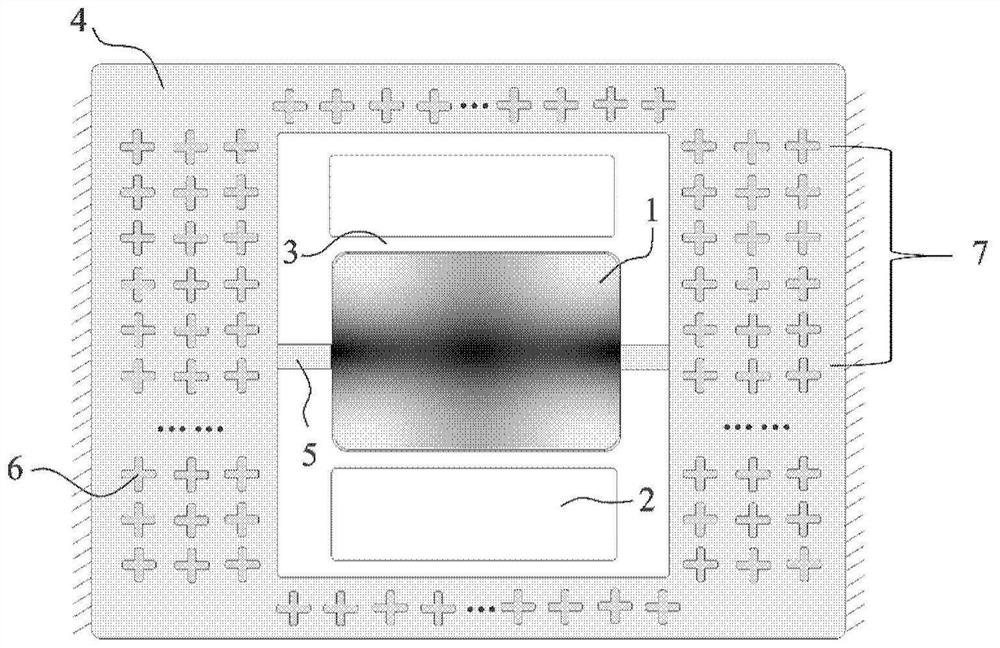

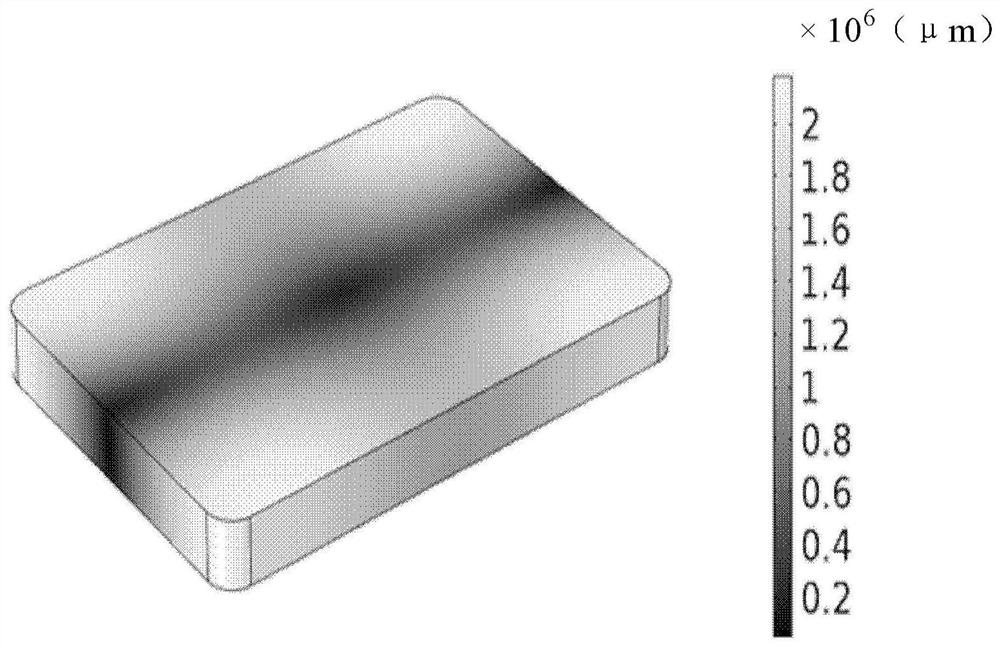

[0032] The disclosure provides an electrostatic resonator based on a periodic elastic wave reflection structure, and the resonator includes a resonance unit, an electrode, a dielectric layer, a base, a supporting structure and a periodic elastic wave reflection structure. By setting the minimum repeating unit on the substrate to form a periodic elastic wave reflection structure, a stop band is formed on the resonator substrate, thereby further reducing the anchor point loss of the resonator and greatly stably improving the quality factor of the resonator. In addition, the resonator is small in size and has a high quality factor, which effectively avoids the limitation of lithography precision, is easy to process, is conducive to improving the yield rate, realizes large-scale batch production of devices, significantly reduces costs, and promotes the development of MEMS resonators. In the process of practical application, the present disclosure is universal, and solves the bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com