Inulin-containing low-fat non-dairy creamer, preparation method thereof and inulin-containing low-fat non-dairy creamer beverage

A technology of planting butter powder and inulin, which is applied in the direction of fat-containing food ingredients, food ingredients, edible oil/fat, etc., to achieve the effect of long storage time, reducing content, and promoting the absorption of nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

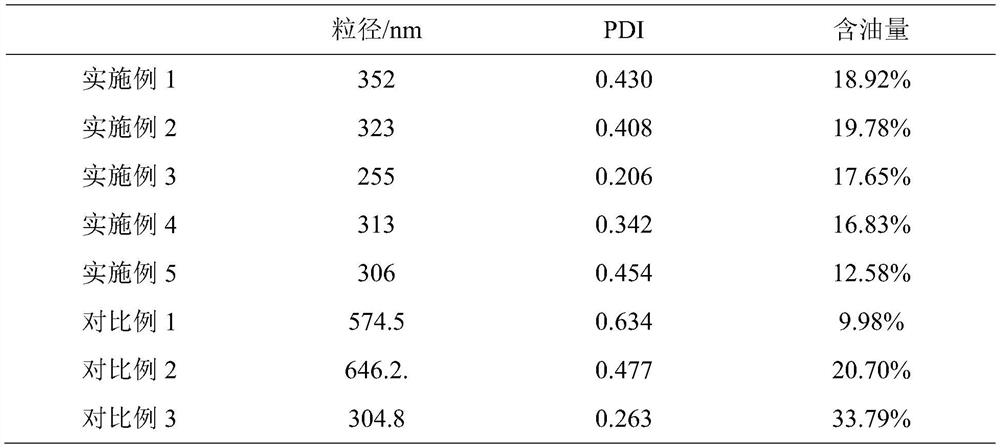

Examples

Embodiment 1

[0026] The inulin-containing low-fat non-dairy creamer of this implementation is made from the following raw materials:

[0027] Hydrogenated coconut oil 22g, sodium caseinate 15g, corn syrup 55g, gum arabic 5g, sodium stearoyl lactylate 0.7g, glyceryl monostearate 4.3g, inulin 12g, dipotassium hydrogen phosphate 2g, silicon dioxide 0.3 g.

[0028] The preparation process of the low-fat non-dairy creamer containing inulin of this implementation comprises:

[0029] 1) Water phase preparation: Dissolve sodium caseinate and dipotassium hydrogen phosphate in hot water at 75°C and fully dissolve them; then add corn syrup, gum arabic, and inulin and mix thoroughly, and control the temperature at 75°C.

[0030] 2) Oil phase preparation: melt the hydrogenated coconut oil at 60-70° C., add sodium stearoyl lactylate and fatty acid glycerol monostearate after melting to fully dissolve.

[0031] 3) After fully mixing the oil phase and the water phase, carry out emulsification and steril...

Embodiment 2

[0035] The inulin-containing low-fat non-dairy creamer of this implementation is made from the following raw materials:

[0036] Hydrogenated coconut oil 25g, sodium caseinate 14g, corn syrup 60g, gum arabic 6g, sodium stearoyl lactylate 0.8g, glyceryl monostearate 4.3g, inulin 14g, dipotassium hydrogen phosphate 2g, silicon dioxide 0.3 g.

[0037] The preparation process of the low-fat non-dairy creamer containing inulin of this implementation comprises:

[0038] 1) Water phase preparation: Dissolve sodium caseinate and dipotassium hydrogen phosphate in hot water at 80°C and fully dissolve them; then add corn syrup, gum arabic, and inulin and mix thoroughly, and control the temperature at 75°C.

[0039] 2) Oil phase preparation: melt the hydrogenated coconut oil at 60-70° C., add sodium stearoyl lactylate and fatty acid glycerol monostearate after melting to fully dissolve.

[0040] 3) After fully mixing the oil phase and the water phase, carry out emulsification and steril...

Embodiment 3

[0044] The inulin-containing low-fat non-dairy creamer of this implementation is made from the following raw materials:

[0045] Hydrogenated coconut oil 20g, sodium caseinate 10g, corn syrup 55g, gum arabic 5g, sodium stearoyl lactylate 0.7g, glyceryl monostearate 4.3g, inulin 16g, dipotassium hydrogen phosphate 2g, silicon dioxide 0.3 g.

[0046] The preparation process of the low-fat non-dairy creamer containing inulin of this implementation comprises:

[0047] 1) Water phase preparation: Dissolve sodium caseinate and dipotassium hydrogen phosphate in hot water at 80°C, fully dissolve them; then add corn syrup, gum arabic, and inulin and mix thoroughly, and control the temperature at 80°C.

[0048] 2) Oil phase preparation: melt the hydrogenated coconut oil at 60-70° C., add sodium stearoyl lactylate and fatty acid glycerol monostearate after melting to fully dissolve.

[0049] 3) After fully mixing the oil phase and the water phase, carry out emulsification and sterilizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com