Method for preparing degreased insect powder and insect oil from hermetia illucens

A technology for black soldier flies and fresh soldier flies, which is applied in the fields of application, animal feed, additional food elements, etc., can solve the problems of uneconomical transportation, high electricity consumption, and poor degreasing, etc., and achieve good utilization value and operating cost. Low, shelf-life extension effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

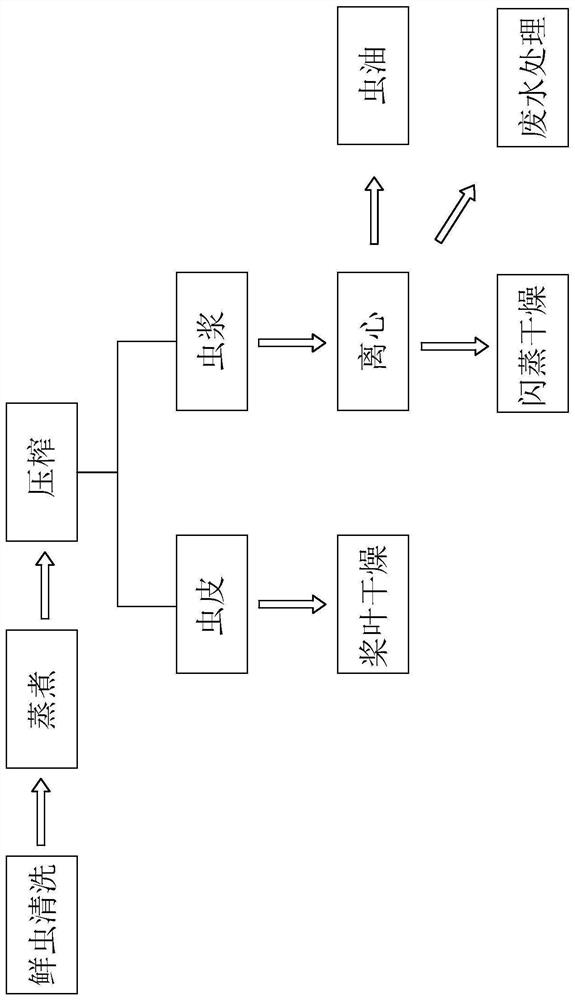

[0057] Step 1), after harvesting the fresh worms of black soldier flies, clean the attached insect powder and impurities through the insect washing machine;

[0058] Step 2), then put the cleaned black soldier fly fresh worms into the cooking pot and cook at 100 degrees Celsius for 30 minutes to kill the living larvae. This process can be continuous, and mature products can be used;

[0059] Step 3), the boiled fresh worms are lifted out of the water by the screw, filtered and dried, and transported to the crushing system; the squeezing system adopts a double-shaft press, which can crush the worm skin and send out the worm pulp inside the skin sac, thereby Also formed solid-liquid separation, obtains the solid slag skin of 45% volume (water content is at 55%) and the insect slurry mixture of 55% volume (water content is at 90%);

[0060] Step 4) Transport the worm pulp mixture to a three-phase centrifuge to separate oil, water, and slag, wherein 10% by volume of grease (i.e. i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com