Dietary fiber soda water and production process thereof

A technology of dietary fiber and production process, which is applied in the field of dietary fiber soda water and its production process, and can solve the problems of single taste and use of soda water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

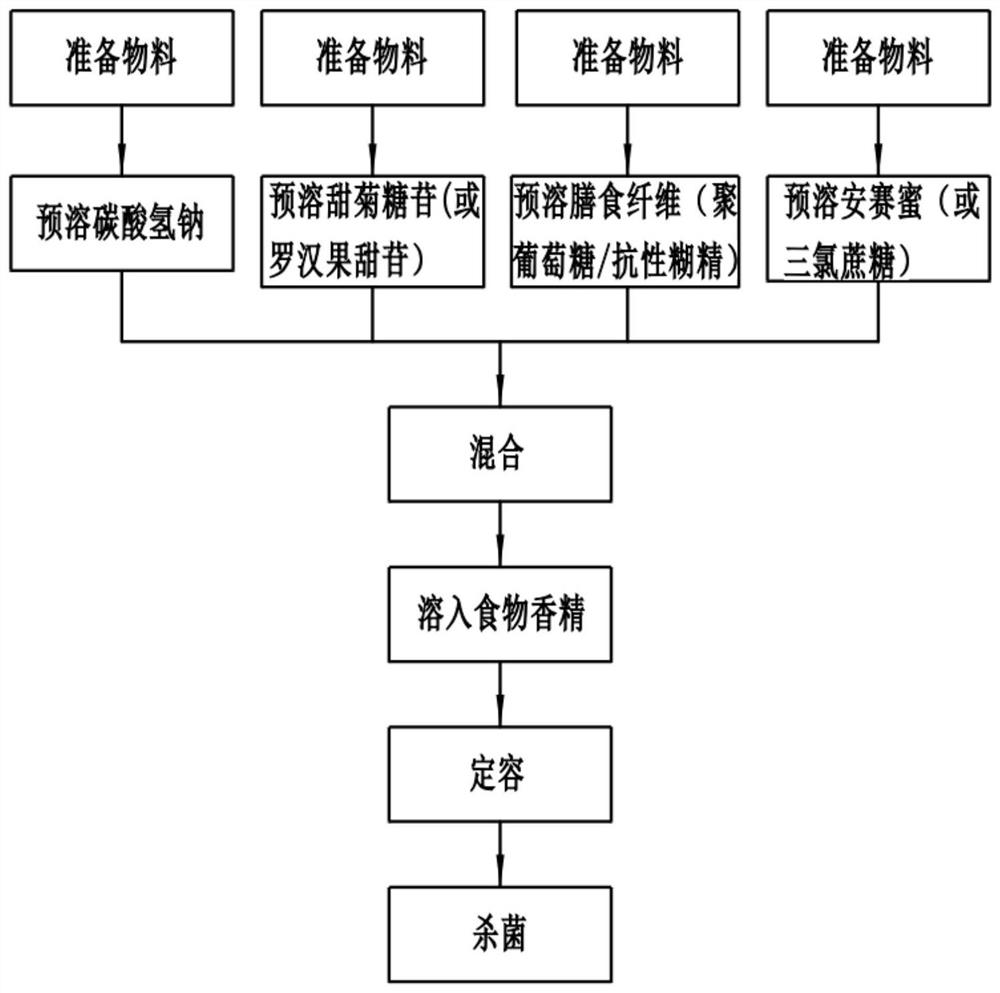

[0042] Basic as attached figure 1 Shown: a kind of dietary fiber soda water preparation process, comprises the following steps:

[0043] Step 1, prepare materials, including the deployment of water, sodium bicarbonate, steviol glycoside, sucralose, dietary fiber and food flavor; 995 parts of the deployment water, 0.25 parts of sodium bicarbonate, 0.15 parts of steviol glycoside, resistant dextrin 2 1 part, 1.6 parts of sucralose, 1 part of food flavor.

[0044] Step 2, pre-dissolve sodium bicarbonate, prepare the first pre-dissolution bucket, dissolve sodium bicarbonate in 180L of preparation water, and use the first stirrer to stir;

[0045] Step 3, pre-dissolve steviol glycosides, prepare a second pre-dissolution tank, dissolve steviosides in 180L of preparation water, and use the second stirrer to stir;

[0046] Step 4, pre-dissolve the sucralose, prepare the third pre-dissolution tank, dissolve the sucralose in 180L of prepared water, and use the third stirrer to stir; ...

Embodiment 2

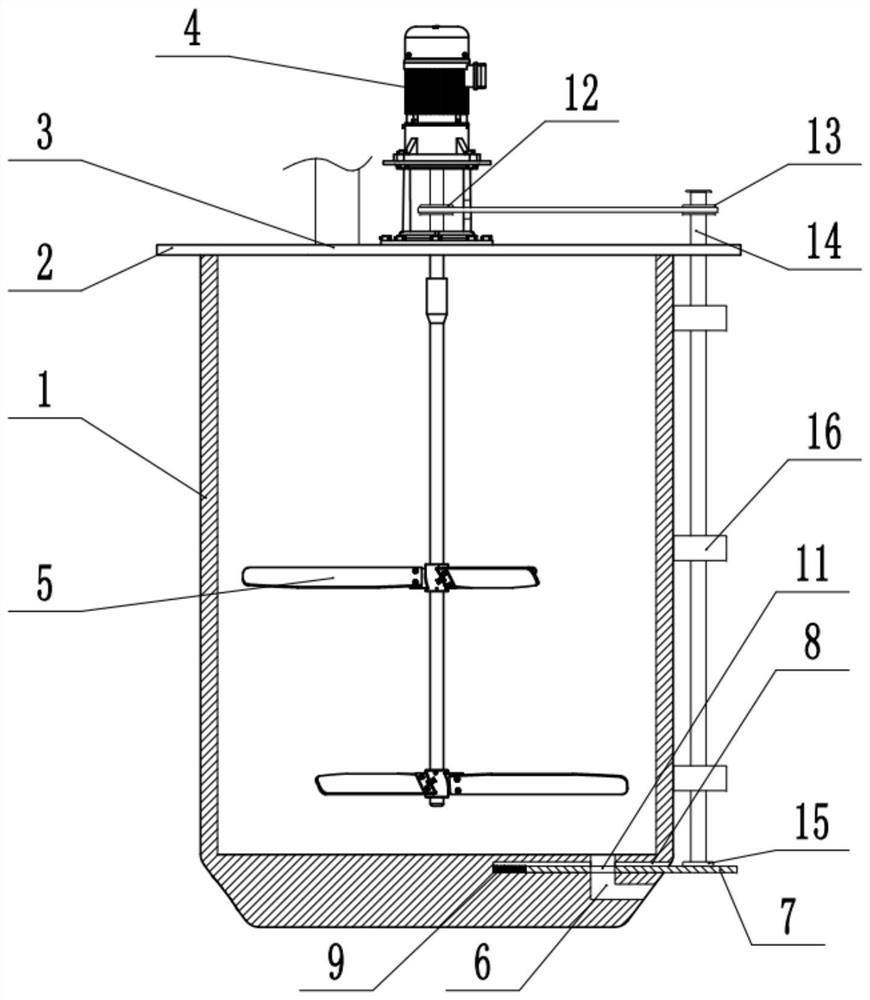

[0054] The difference between this embodiment and Embodiment 1 is that, as attached figure 2 , attached image 3 As shown, the blending cylinder includes a cylinder body 1, the top of the cylinder body 1 is fixedly connected with a baffle plate 2, the two ends of the baffle plate 2 extend out of the outer wall of the cylinder body 1, and the baffle plate 2 is provided with a feeding hole 3. The top bolt of the baffle plate 2 is fixed with the fifth drive motor 4, the output shaft of the fifth drive motor 4 is vertically rotatably connected to the bottom of the baffle plate 2, and the output shaft of the fifth drive motor 4 extends in the cylinder body 1, the fifth The output shaft of the motor is connected with the coaxial key and is fixed with the fifth agitator 5 .

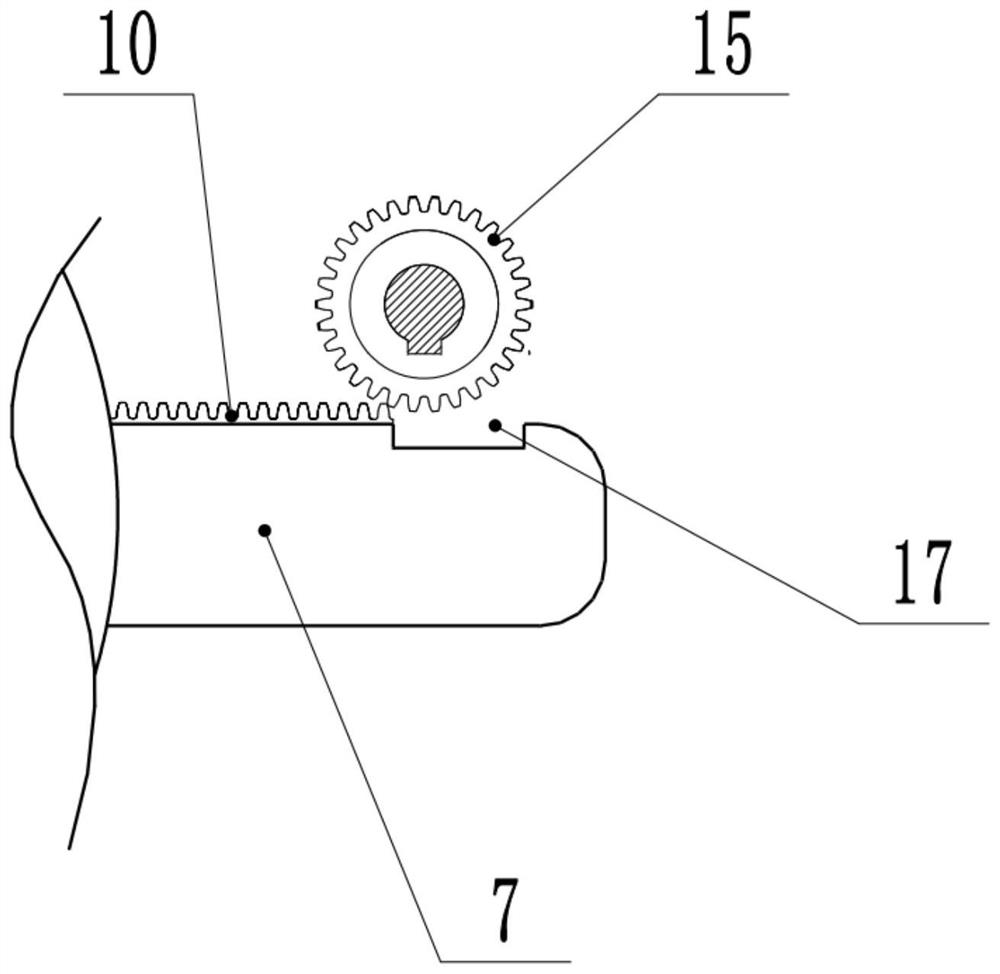

[0055] The bottom of the cylinder body 1 is provided with a discharge hole 6, and the discharge hole 6 is connected with a discharge pipe. There is also a horizontal slideway 8 at the bottom of the cylinder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com