Method for beneficiation and separation of copper-zinc sulfide ore

A sulfide ore, copper-zinc technology, applied in the field of mineral processing, can solve problems such as long process flow, high grinding cost, loss of metal resources, etc., achieve the effect of reducing costs, reducing metal loss, and improving overall economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

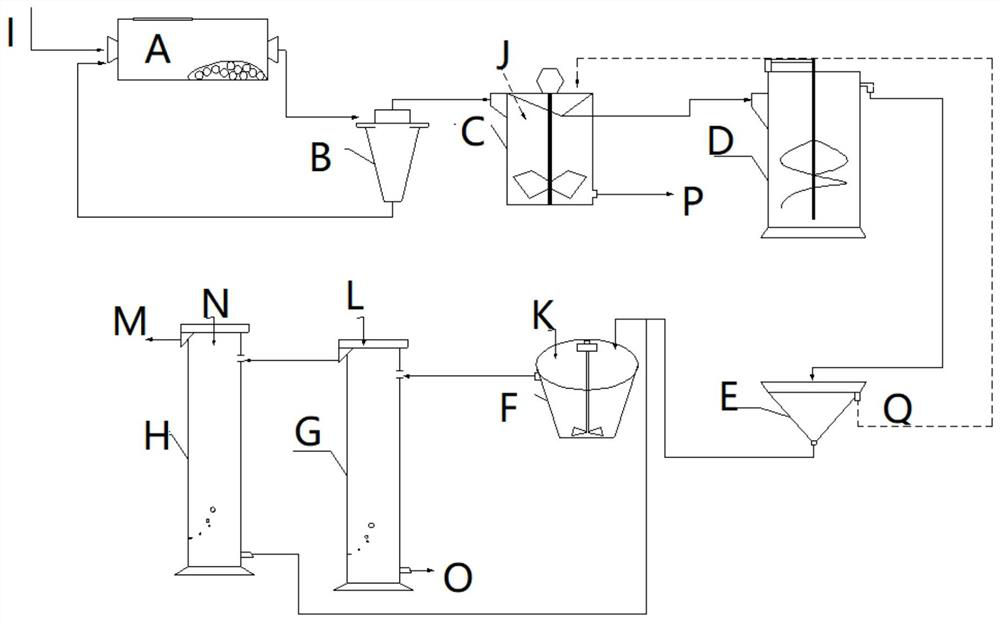

Method used

Image

Examples

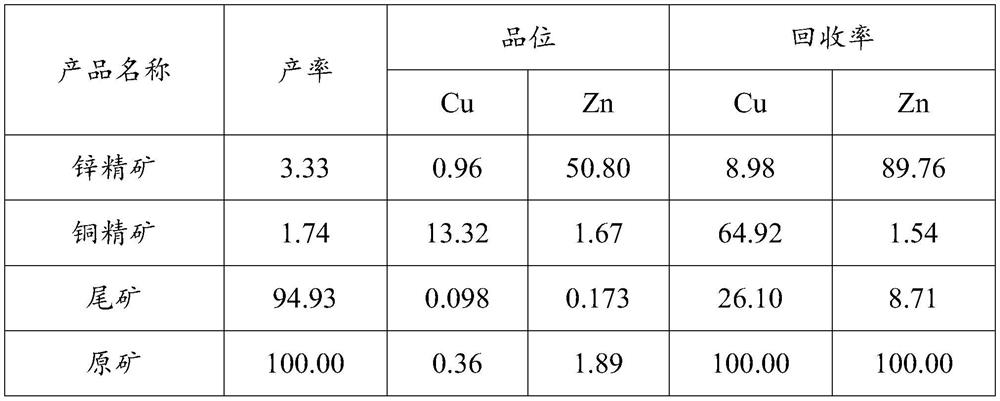

Embodiment 1

[0042] A copper-zinc sulfide mine in Yunnan is a typical copper-zinc mineral fine-grained disseminated low-grade copper-zinc mine. In the raw ore produced by the mine, copper mainly occurs in the form of primary copper sulfide (chalcopyrite), with a distribution rate of 90.45%. Zinc mainly occurs in the form of primary zinc sulfide (sphalerite), with a distribution rate of 95.65%. In addition to chalcopyrite and sphalerite, it also contains a small amount of pyrite, accounting for 4.3% of the total mineral content. The gangue minerals are mainly quartz, and contain some calcite mica minerals. Chalcopyrite and sphalerite in the ore are The fine particles are embedded, and part of them are interspersed in the fissures of pyrite in a mutually wrapped state.

[0043] Table 1 ore chemical multi-element analysis results / %

[0044] components Cu Zn Pb Fe As S content 0.36 1.89 0.02 3.12 <0.01

3.19 components SiO 2

Al 2 o 3

MgO ...

Embodiment 2

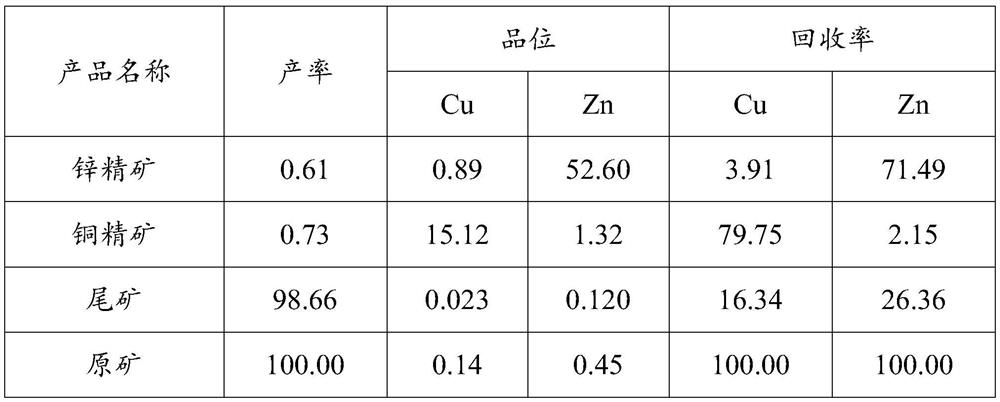

[0056] A low-grade copper-zinc sulfide ore in Inner Mongolia contains 0.14% Cu and 0.44% Zn. figure 1 The process shown treats the mine's raw ore.

[0057] (1) After the raw ore is ground and classified, the selected fineness is -0.074mm, which accounts for 70% of the raw ore pulp. The raw ore pulp is flotation in the flotation machine, and ethylthiocarbamate is added in the flotation process, and the consumption is 60g / t, to obtain copper-zinc mixed concentrate and mixed floating tailings;

[0058] (2) The copper-zinc mixed concentrate is processed by the vertical mill, and the particle size of the vertical mill overflow product is controlled to be -0.039mm, accounting for 85%. 80g / t acetic acid until the pH of the pulp reaches 5, and add 600g / t copper sulfate and 120g / t MIBC, after stirring, the pulp is sent to the total micro-bubble flotation column, and the air volume of the flotation column is controlled to be 0.5m 3 / h, the height of the foam layer is 25cm, the foam c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com