Tool for four-axis four-station machining center

A processing center and four-station technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large volume, low pressure, low tooling efficiency, etc., to increase the clamping space, reduce the space, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

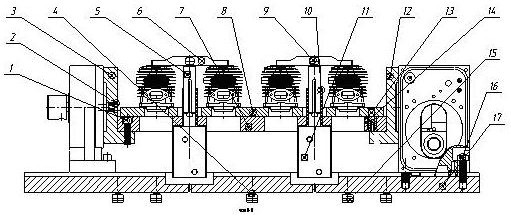

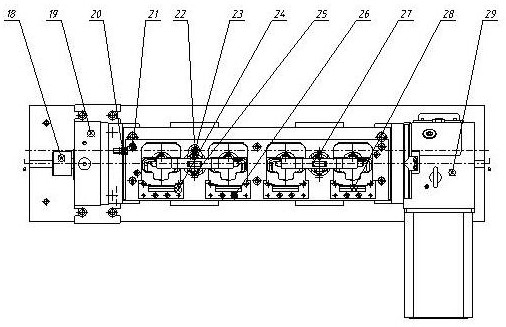

[0018] Such as Figure 1 to Figure 2 As shown, the tooling for a four-axis four-station machining center of the present invention adopts a technical solution that includes a base plate 17, a tailstock 19 and a headstock 29, and the tailstock 19 and the headstock 29 are installed on the On the base plate 17, the tailstock 19 and the headstock 29 are respectively provided with a tailstock L-shaped plate 3 and a headstock L-shaped plate 12, and the tailstock L-shaped plate 3 and the headstock L-shaped A bridge plate 7 is provided between the plates 12, and a positioning plate 8 is provided on the bridge plate 7; two sets of installation grooves are opened on the bridge plate 7 and the bottom plate 17, and an oil cylinder 11 is arranged in the installation groove. The telescoping end of the oil cylinder 11 is provided with a push rod 5, and the positioning plate 8 is provided with a through hole matching the size of the push rod 5, and the push rod 5 is connected with a pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com