Method for improving yield of Li<+> in sodium sulfate subtype salt lake brine

A technology of salt lake brine and sodium sulfate, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of improving the yield, reducing the hindering effect, and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

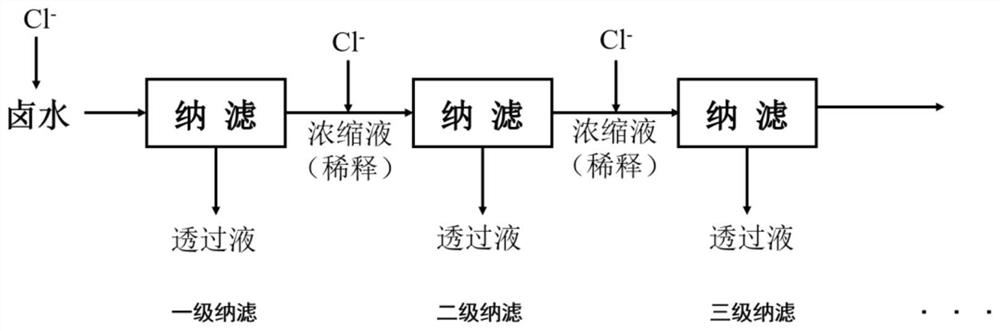

[0038] The sodium sulfate subtype salt lake brine in Tibet was used as raw material to extract lithium by nanofiltration. The main components are as follows: Li + : 0.239g / L, Mg 2+ : 0.786g / L, Na + : 15.066g / L, Cl - : 12.27g / L, SO 4 2- : 18.8g / L. Take 20L of the above-mentioned brine as a raw material, adopt 1812 nanofiltration separation equipment produced by Xiamen Fumei Technology Co., Ltd., the nanofiltration membrane is Dow DK2540F30, the nanofiltration pressure is 40bar, and the volume ratio of nanofiltration permeate and concentrate at all levels is 3 : 1, after the end of the primary nanofiltration process, MgCl 2 as Cl - Introduce the source, introduce Cl in the concentrate - , dilute the concentrate twice with RO water, introduce Cl - And the Cl in the diluted concentrate - The concentration is 10g / L (you can also introduce Cl after dilution - ; The effect of dilution is mainly to reduce the concentration of the total salt content in the solution, and the c...

Embodiment 2

[0040] The sodium sulfate subtype salt lake brine in Tibet was used as raw material to extract lithium by nanofiltration. The main components are as follows: Li + : 0.239g / L, Mg 2+ : 0.786g / L, Na + : 15.066g / L, Cl - : 12.27g / L, SO 4 2- : 18.8g / L. Take 20L of the above-mentioned brine as a raw material, adopt 1812 nanofiltration separation equipment produced by Xiamen Fumei Technology Co., Ltd., the nanofiltration membrane is Dow DK2540F30, the nanofiltration pressure is 40bar, and the volume ratio of nanofiltration permeate and concentrate at all levels is 3 : 1, NaCl is used as Cl after the end of the primary nanofiltration process - Introduce the source,, introduce Cl in the concentrate - , dilute the concentrate twice with RO water, introduce Cl - And the Cl in the diluted concentrate - Concentration is 10g / L, above-mentioned introduced Cl - And the diluted concentrated solution is subjected to secondary nanofiltration. After the secondary nanofiltration, the prima...

Embodiment 3

[0042] The sodium sulfate subtype salt lake brine in Tibet was used as raw material to extract lithium by nanofiltration. The main components are as follows: Li + : 0.239g / L; Mg 2+ : 0.786g / L, Na + : 15.066g / L, Cl - : 12.27g / L, SO 4 2- : 18.8g / L. Take 20L of the above-mentioned brine as a raw material, adopt 1812 nanofiltration separation equipment produced by Xiamen Fumei Technology Co., Ltd., the nanofiltration membrane is Dow DK2540F30, the nanofiltration pressure is 40bar, and the volume ratio of nanofiltration permeate and concentrate at all levels is 3 : 1, with MgCl 2 as Cl - Introduce the source, and introduce the concentration of Cl in the raw brine as 5g / L - , introducing Cl - The final raw material brine is subjected to primary nanofiltration, and Cl is continuously introduced into the primary concentrate obtained in the primary nanofiltration process. - , dilute the primary concentrated solution by 2 times with RO water, and introduce Cl - And dilute Cl i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com