Printing ink for PCB of LED display screen, preparation method of LED display module using printing ink and LED display screen

A technology of LED display screen and PCB board, which is applied in the direction of printing ink, photographic plate-making process of patterned surface, and photosensitive material used in optical mechanical equipment, etc. advanced questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

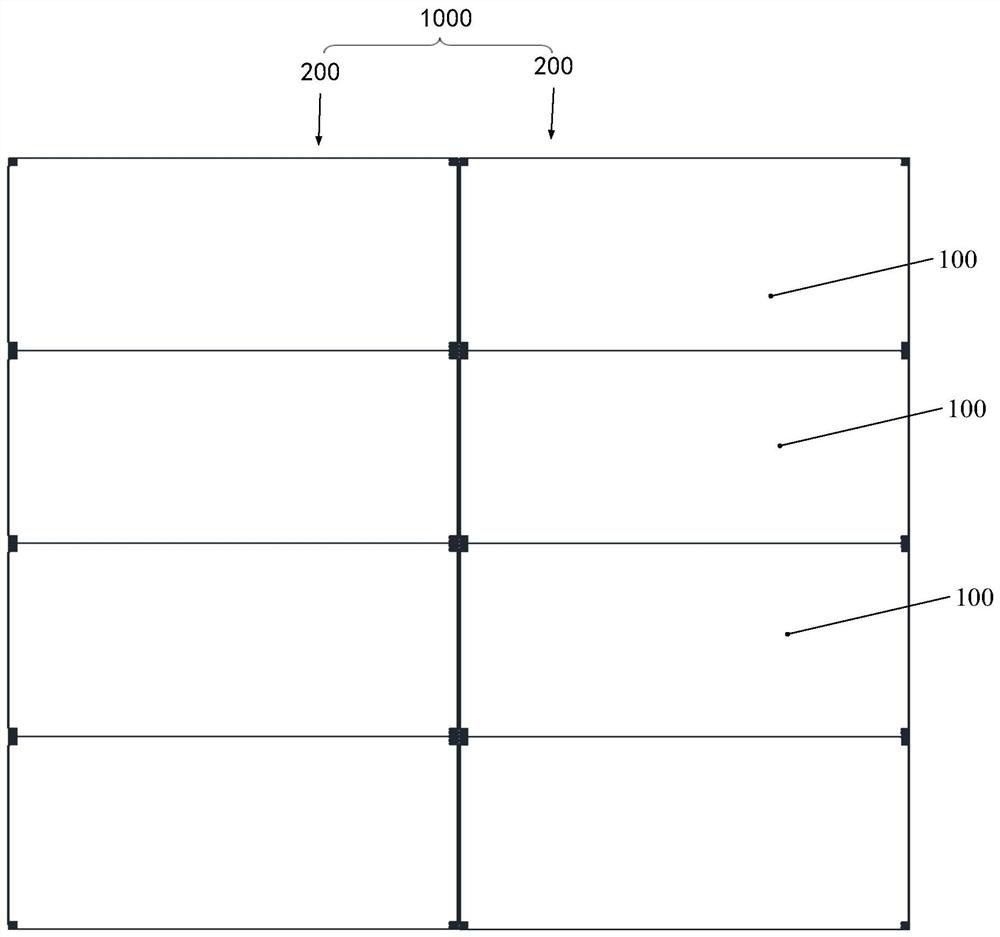

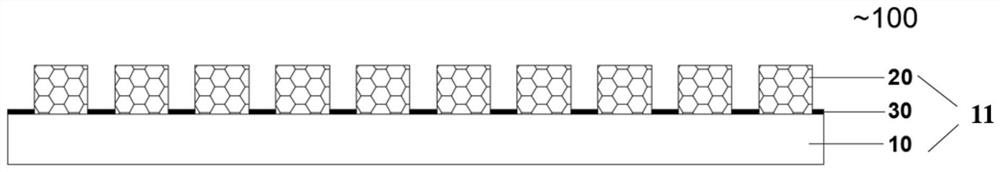

[0055] Correspondingly, the embodiment of the present application also provides a method for preparing an LED display module using the above-mentioned matting solder resist ink, including the following steps:

[0056] S100, coating or printing the matt solder resist ink obtained by mixing the first component and the second component on the first surface of the PCB, and then pre-baking, exposure treatment, development treatment, and post-baking, Forming a patterned matte solder resist ink layer;

[0057] S200, mounting a plurality of LED lamp beads on the area of the first surface not covered by the matting solder resist ink layer to obtain an LED display module.

[0058] In step S100, the first surface of the PCB board is the side surface of the PCB board to be mounted with LED lamp beads. The above-mentioned coating methods may include brush coating, spray coating, doctor blade coating or spin coating, etc., and the specific printing method may be screen printing, and its ...

Embodiment 1

[0068] A kind of matting solder resist ink for LED display PCB board, comprises the first component and the second component that store separately, and described first component comprises each raw material of following mass percentage content:

[0069] Oligomer (specifically modified o-methyl novolak epoxy acrylic resin, viscosity at 60°C is 2500mPa·s): 35%;

[0070] Photoinitiator: 10%, specifically 7% of 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-propanone and 3% of 2-isopropylthioxanthone ;

[0071] Nano black filler (specifically carbon microspheres with a particle size of 30nm): 10%;

[0072] Matting agent (specifically fumed silica, secondary particle size is 10 μm): 18%;

[0073] Coupling agent (specifically aminopropyltriethoxysilane): 2%;

[0074] DBE solvent: 25%;

[0075] Described second component comprises each raw material of following mass percentage content:

[0076] Epoxy resin (specifically novolac type epoxy resin, the viscosity at 25°C is 2000mPa·s...

Embodiment 2

[0088] A kind of matting solder resist ink for LED display PCB board, comprises the first component and the second component that store separately, and described first component comprises each raw material of following mass percentage content:

[0089] Oligomer (specifically novolac epoxy acrylic resin, viscosity at 60°C is 3000mPa·s): 33%;

[0090] Photoinitiator 10%, specifically 7% of 2-methyl-1-(4-methylthiophenyl)-2-morpholine-1-propanone and 3% of 2-isopropylthioxanthone) ;

[0091] Nano black filler (specifically carbon microspheres with a particle size of 30nm): 10%;

[0092] Matting agent (specifically fumed silica, secondary particle size is 10 μm): 20%;

[0093] Coupling agent (specifically aminopropyltriethoxysilane): 2%;

[0094] DBE solvent: 25%;

[0095] Described second component comprises each raw material of following mass percentage content:

[0096] Epoxy resin (specifically bisphenol F type epoxy resin, the viscosity at 25°C is 1500mPa·s): 35%;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com