Method for producing D-amino acid oxidase through fermentation

An amino acid and oxidase technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, redox enzymes, etc., can solve the problem of low biomass, inability to obtain a large number of bacteria with high enzyme activity, low enzyme activity of bacteria, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The genetically engineered bacteria are activated on a slant, and the colonies are picked up and inoculated into a shaker flask equipped with a first-level seed medium for cultivation as a first-level seed solution. The cultivation conditions of the first-level seed solution are: pick a single colony into Streptomycin was used as an antibiotic in a 250mL shake flask with a liquid volume of 50mL, placed in a constant temperature shaking incubator at 37°C, and shaken at 180rpm for 12h.

[0047] Inoculate the first-level seed liquid into the shaking flask equipped with the second-level seed medium and cultivate it as the second-level seed liquid. g / L streptomycin sulfate was used as an antibiotic in a 500mL shake flask with a liquid volume of 100mL, placed in a constant temperature shaking incubator at 37°C, and shaken at 180rpm for 10-12h.

[0048] Take the inoculation amount as 10% to inoculate the secondary seed liquid into the 2L fermentation medium in the 5L fermenter...

Embodiment 2

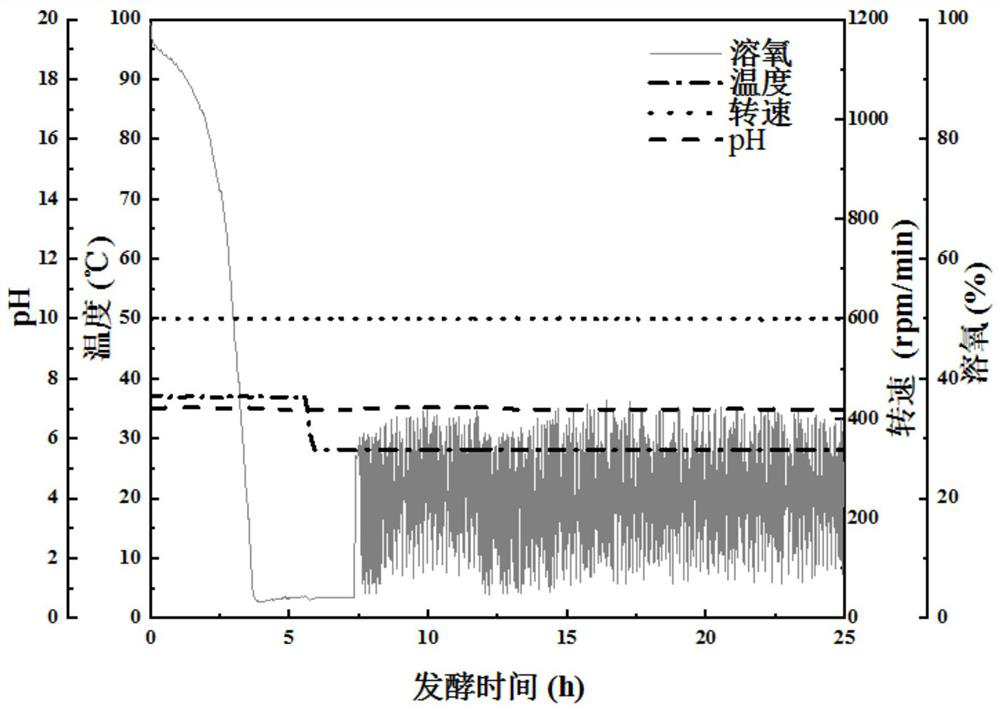

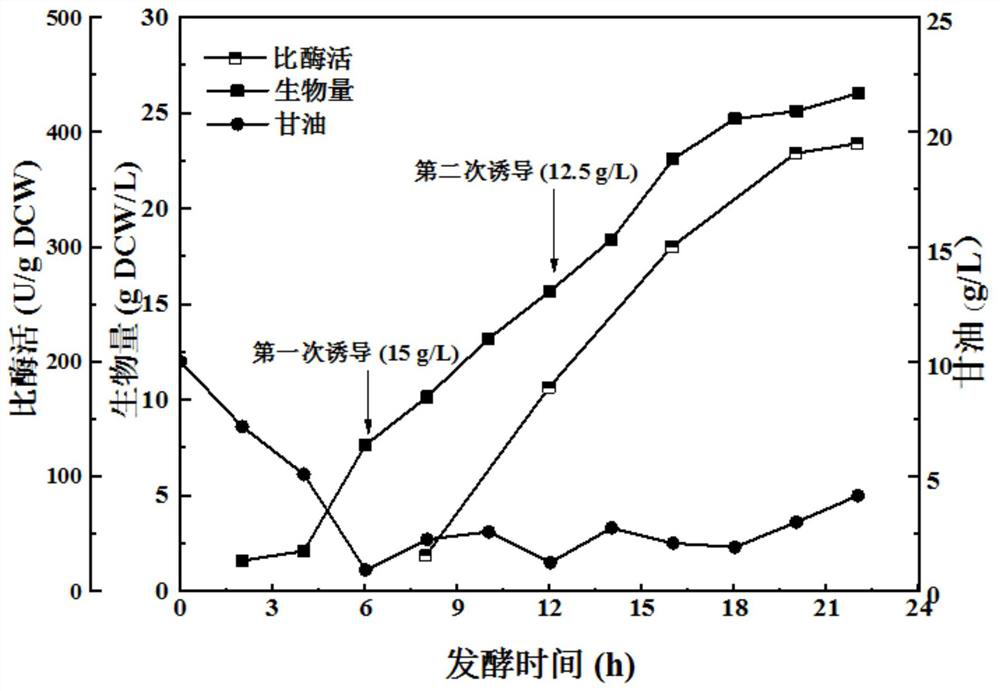

[0056] Fermentation method, condition are all the same as embodiment 1 except following changes. Set the feeding mode to DO-STAT, where the DO setting value is 30%, and when DO exceeds 0.1%, automatic feeding. The fermentation time is 22-24h, and when the biomass growth of the bacteria slows down, the fermentation is stopped. After the fermentation is completed, the fermentation broth is centrifuged at 8000 rpm for 10 minutes with a freeze-drying centrifuge to collect the bacteria. It is determined by experiments that the biomass of the thalline obtained by fed-batch fermentation by the method is 23.4g DCW / L, and the specific enzyme activity of the thalline is 388.3U / gDCW. The parameters of the fermentation process are shown in figure 1 .

Embodiment 3

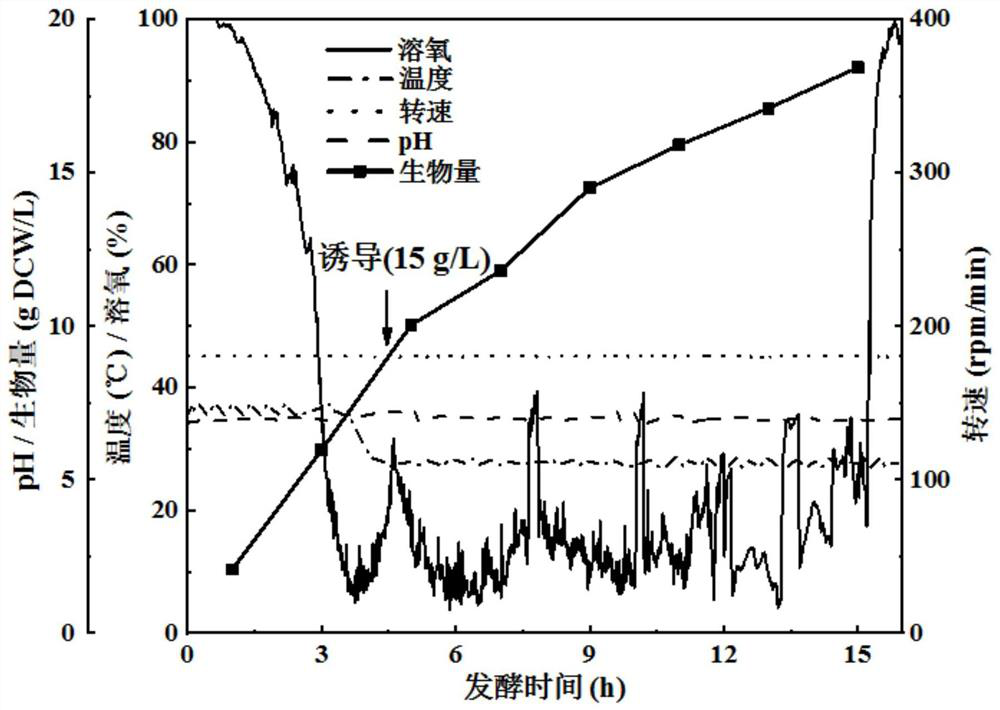

[0058] Fermentation method, condition are all the same as embodiment 1 except following changes. Set the feeding mode to DO-STAT, where the DO setting value is 50%, and when DO exceeds 0.1%, automatic feeding. The fermentation time is 22-24h, and when the biomass growth of the bacteria slows down, the fermentation is stopped. After the fermentation is completed, the fermentation broth is centrifuged at 8000 rpm for 10 minutes with a freeze-drying centrifuge to collect the bacteria. It is determined by experiments that the biomass of the thalli obtained by fed-batch fermentation by the method is 20.4g DCW / L, and the specific enzyme activity of the thalline is 377.3U / gDCW.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com