Preparation method of core-shell nano polymer and application of core-shell nano polymer in cyclic regeneration of coenzyme

A technology of recycling and polymers, applied in multi-enzyme systems, immobilized on or in the direction of inorganic carriers, can solve the problems of low efficiency and inability to fold correctly, and achieve the effect of increased conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

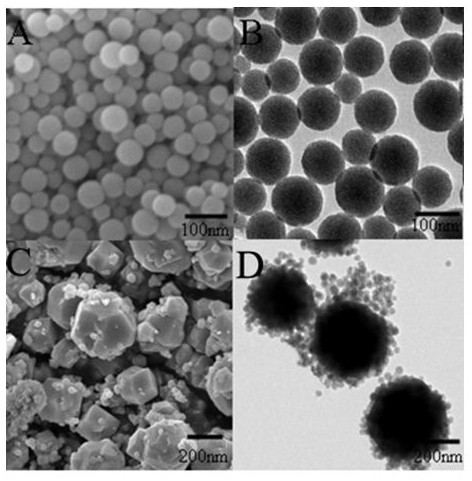

[0026] Preparation of coenzyme polymer: Weigh 2g of carboxyl-modified mesoporous silicon nanoparticles, sonicate in 30mL deionized water for 8-15 minutes, then add a certain amount of coenzyme NAD + , adjust the pH to 4.5-5.5 with 0.5M hydrochloric acid solution, and stir magnetically at 25-30°C. Add 50 mg of water-soluble carbodiimide EDC continuously within 5 minutes, continue to add hydrochloric acid solution dropwise during the addition process, keep the pH at 4.5-5.5, and stir magnetically at 25-30°C for 25-30h. After the reaction, centrifuge to remove unreacted NAD + and other impurities, washed with 0.2M NaCl solution until NAD was not detected in the washing solution + . Finally, freeze-dry to obtain immobilized coenzyme.

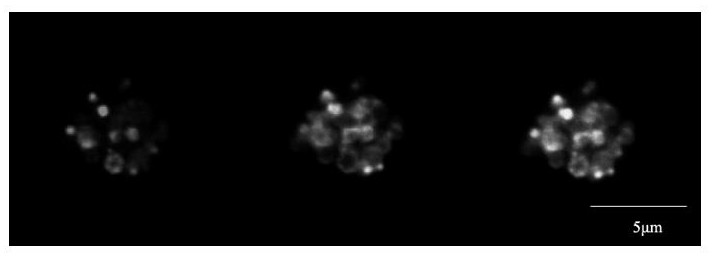

[0027] In situ co-immobilization of multiple enzymes: 0.5-1mg alcohol dehydrogenase, 0.5-1mg lactate dehydrogenase, 1-2mg MSN-NAD + Add 5-10mL zinc acetate (40mM) solution, quickly add 5-10mL (2.8mM) 2-methylimidazole under stirring at room temp...

Embodiment 2

[0031]Weigh 2 g of group-modified mesoporous silicon nanoparticles, ultrasonicate in 30 mL of deionized water for 8-15 minutes, add a certain amount of coenzyme NADPH, and stir magnetically at 25-30°C. Add 50 mg of water-soluble carbodiimide EDC continuously within 5 minutes, control the pH to maintain at 7.4-8 during the addition, and stir magnetically at 25-30° C. for 25-30 h. After the reaction, unreacted NADPH and other impurities were removed by centrifugation, and washed with 0.2M NaCl solution until no NADPH was detected in the washing solution. Finally, freeze-dry to obtain immobilized coenzyme. Glutamate dehydrogenase and glucose-6-phosphate dehydrogenase were co-immobilized and coenzyme polymer encapsulated by in situ growth of ZIF-67 and ZIF-8 materials, respectively. Adding a certain amount of glutamic acid and glucose 6-phosphate initiates the coenzyme cycle and multi-enzyme cascade reaction in the system. In the presence of glutamate dehydrogenase and NADPH in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com