Physical vapor deposition of piezoelectric films

A physical vapor deposition, piezoelectric layer technology, applied in electrical components, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., to reduce overheating, improve downtime, and excellent piezoelectric performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

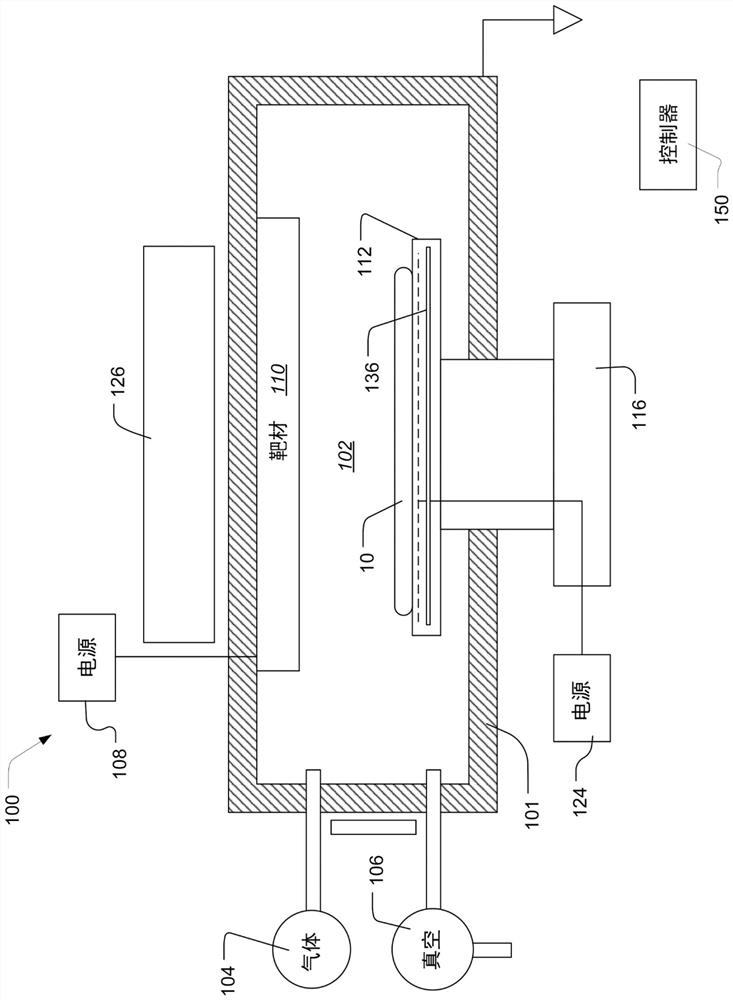

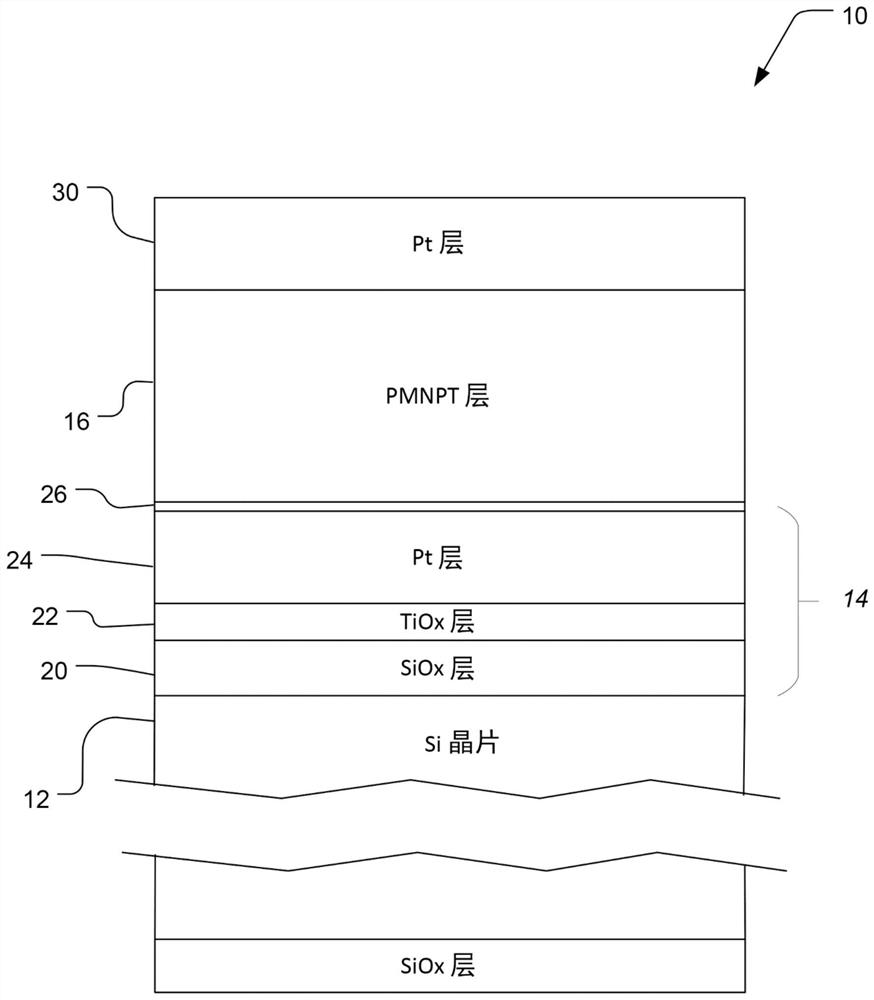

[0014] Fabrication of piezoelectric layers from bulk crystals and deposition of piezoelectric layers using sol-gel techniques are slow processes that do not favor implementation in semiconductor fabrication plants. Bulk crystals require processing in conventional machine shops. Not only is this expensive, but it limits the ability to integrate piezoelectric layers into devices. The sol-gel process requires multiple rounds of deposition and curing, making the process time-consuming. Therefore, it is desirable to deposit piezoelectric materials by physical vapor deposition processes such as sputtering.

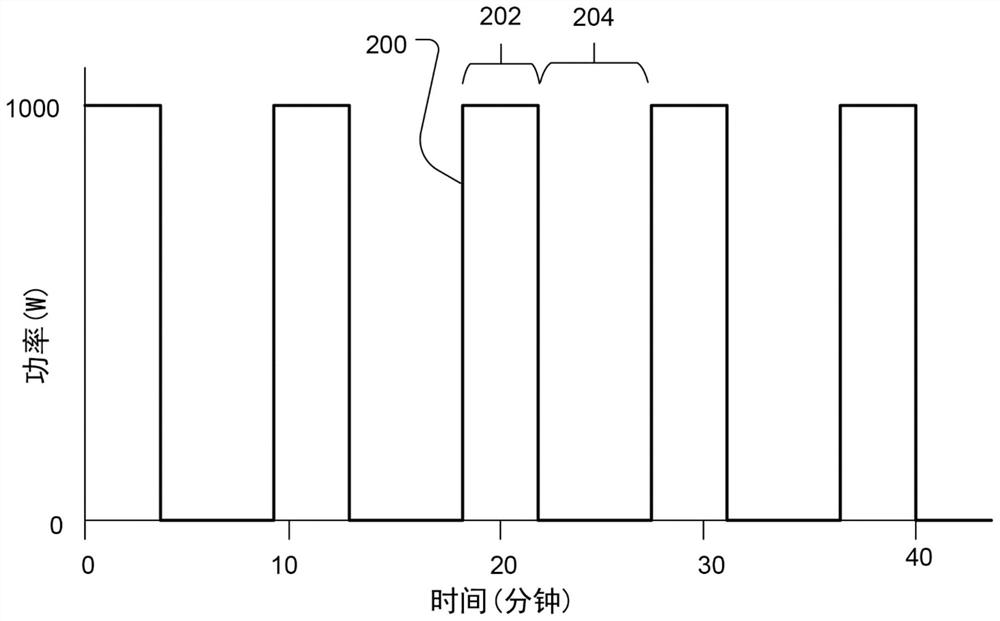

[0015] Fabricating thin films of piezoelectric materials on large-area semiconductor wafers, such as silicon wafers, by physical vapor deposition (PVD) is challenging. For PVD of piezoelectric materials such as PZT or Relax-PT, the target material used in the sputtering process is a ceramic material. However, targets used in chambers may crack or suffer other forms of damage....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com