Corrosion hole forming device for high-voltage aluminum electrolysis electronic aluminum foil

An electronic aluminum foil and aluminum electrolysis technology, which is applied in the electrolysis process and electrolysis components, etc., can solve the problems affecting the uniformity of the distribution of pores, the uniformity of the hole depth, the effect of the corrosion effect of the pores on the upper end of the aluminum foil, and the inability to effectively discharge air bubbles. The uniformity of the hair hole, the reduction of installation costs, and the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

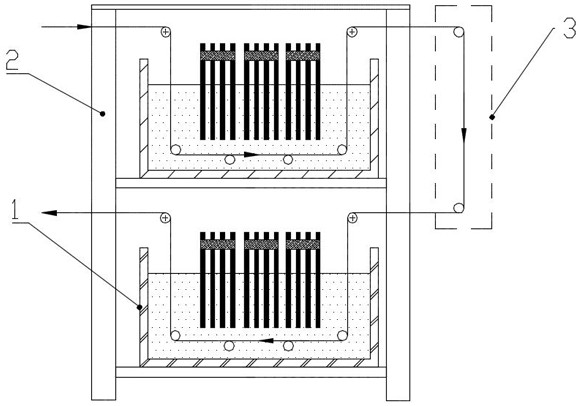

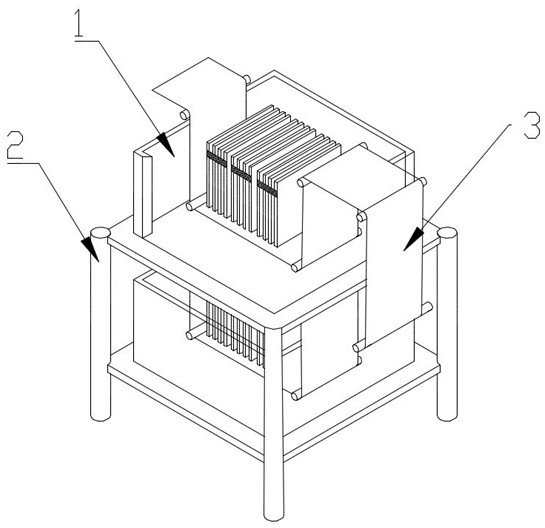

[0034] A corroding perforation device for high-voltage aluminum electrolytic electronic aluminum foil, including two primary perforation slots 1, a bracket 2 and a flipping device 3;

[0035] The support 2 is divided into two layers, and each layer is equipped with a primary hair hole groove 1, and a turning device 3 is provided on the side of the support 2; the turning device 3 includes a transmission roller I8 and a transmission roller II9 , the transmission roller I8 is located above the transmission roller II9;

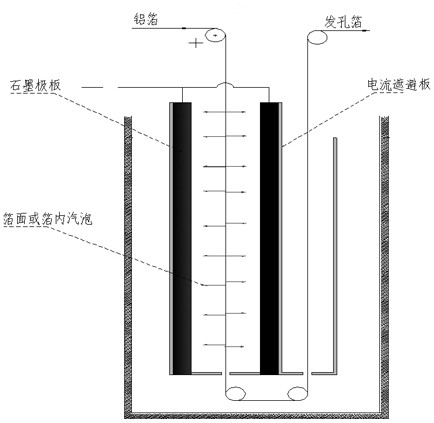

[0036] The primary hair cell 1 includes an electrolyte tank body 4, and the middle part of the electrolyte tank body 4 is provided with 3 groups of graphite pole plate groups 5 vertically downward, and each group of graphite pole plate groups 5 is connected to a high-frequency The negative pole of the switching power supply; the graphite pole plate group 5 includes copper bars 11 and 4 graphite pole plates 10, the graphite pole plates 10 are parallel to each other...

Embodiment 2

[0040]The difference between this embodiment and Embodiment 1 is that: the electrolyte tank body 4 is provided with 2 sets of graphite pole plate groups 5; the graphite pole plate group 5 has 2 graphite pole plates 10, graphite The distance between the pole plates 10 is 20mm; the height of the graphite pole plate group 5 is 400mm. A ceramic roller 7 is arranged below the graphite electrode plate group 5 . When the aluminum foil passes through the bottom surface of each graphite pole plate group 5 to corrode and open holes, the lower part of the aluminum foil is supported by a ceramic copper roller 7 .

[0041] The working principle of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that: the electrolyte tank body 4 is provided with 4 groups of graphite pole plate groups 5; there are 8 graphite pole plates 10 in the graphite pole plate group 5, graphite The distance between the pole plates 10 is 100mm; the height of the graphite pole plate group 5 is 1000mm. Two ceramic rollers 7 are arranged below the graphite plate group 5 . When the aluminum foil passes through the bottom surface of each graphite pole plate group 5 to corrode and open holes, the lower part of the aluminum foil is supported by a ceramic copper roller 7 .

[0044] The working principle of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com