Prefabricated concrete frame system with exposed flat grid floor slabs and exposed truss girders

A frame system and truss beam technology, applied to truss structures, truss beams, floor slabs, etc., can solve the problems of complex installation, increased construction period and cost, and the need to improve the construction technology of prefabricated buildings, so as to reduce cost and increase construction Speed, the effect of reducing plate thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

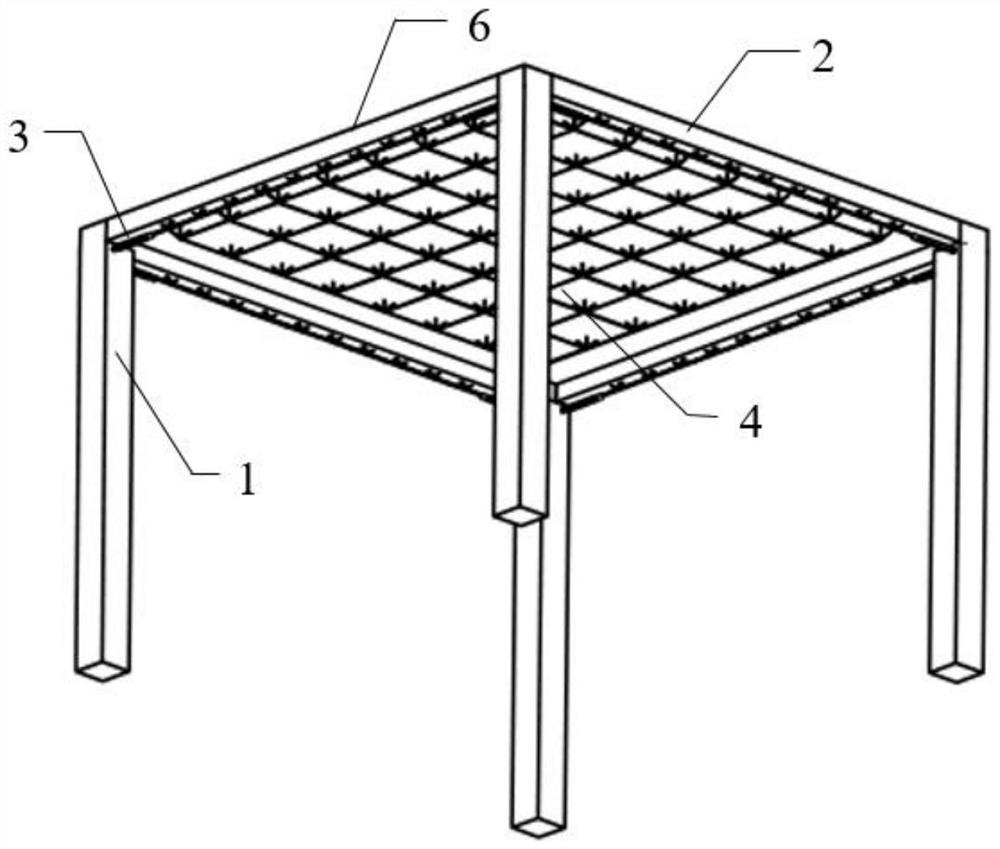

[0042] This example discloses a prefabricated concrete frame system with exposed flat grid floor and exposed truss beams, see figure 1 , including prefabricated concrete columns 1, exposed truss composite beams 2, energy dissipation dampers 3, exposed flat grid frame composite slab bottom plates 4 and post-cast concrete layers 6.

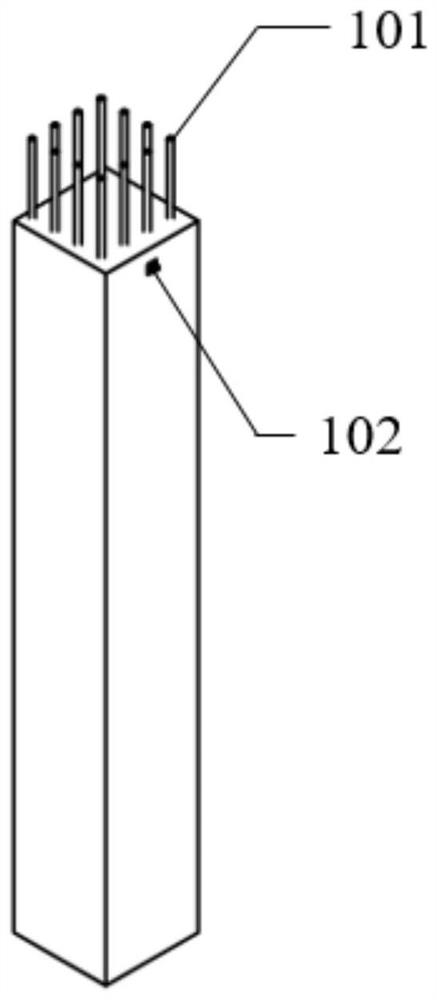

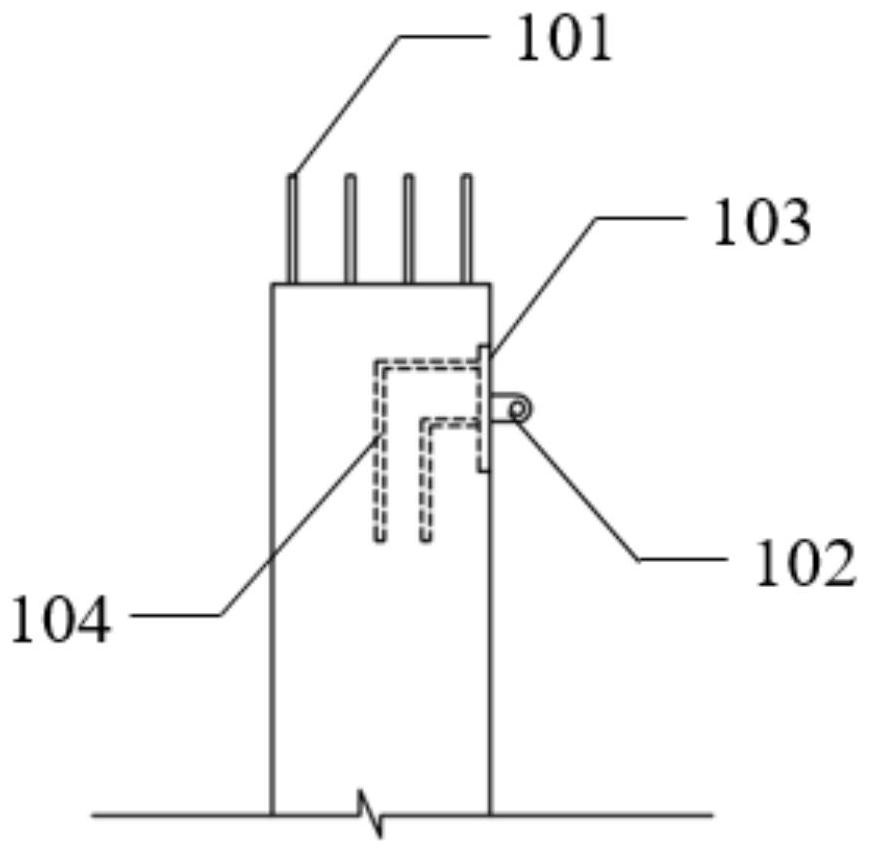

[0043] see figure 2 , 3 , the precast concrete column 1 includes column longitudinal reinforcement 101, column ear plate 102, conversion steel plate 103 and anchoring reinforcement 104; column longitudinal reinforcement 101 is arranged inside the precast concrete column 1, and the reinforcement is drawn out along the column; conversion steel plate 103 is pre-embedded in the precast concrete column 1. The column ear plate 102 and the anchoring steel bar 104 are welded with the conversion steel plate 103, the column ear plate 102 is exposed on the column surface, and the anchoring steel bar 104 is pre-embedded in the precast concrete column 1.

[0...

Embodiment 2

[0050] The main structure of this embodiment is the same as that of Embodiment 1, see Figure 11 , wherein the precast concrete column 1 is a corner column, and the upper chord 2031 of the space truss is bent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com