Spectral selective light absorption structure for solar water gasification

A solar energy and selective technology, applied in the field of solar energy utilization, can solve the problems of reducing photothermal conversion efficiency, large radiation loss, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

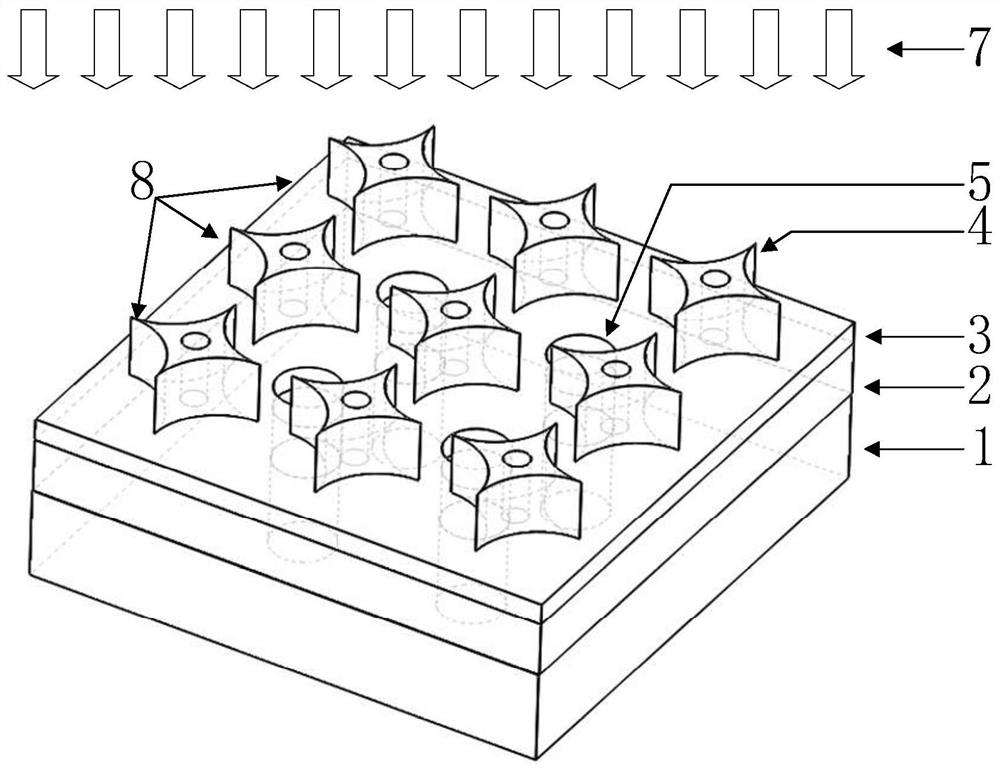

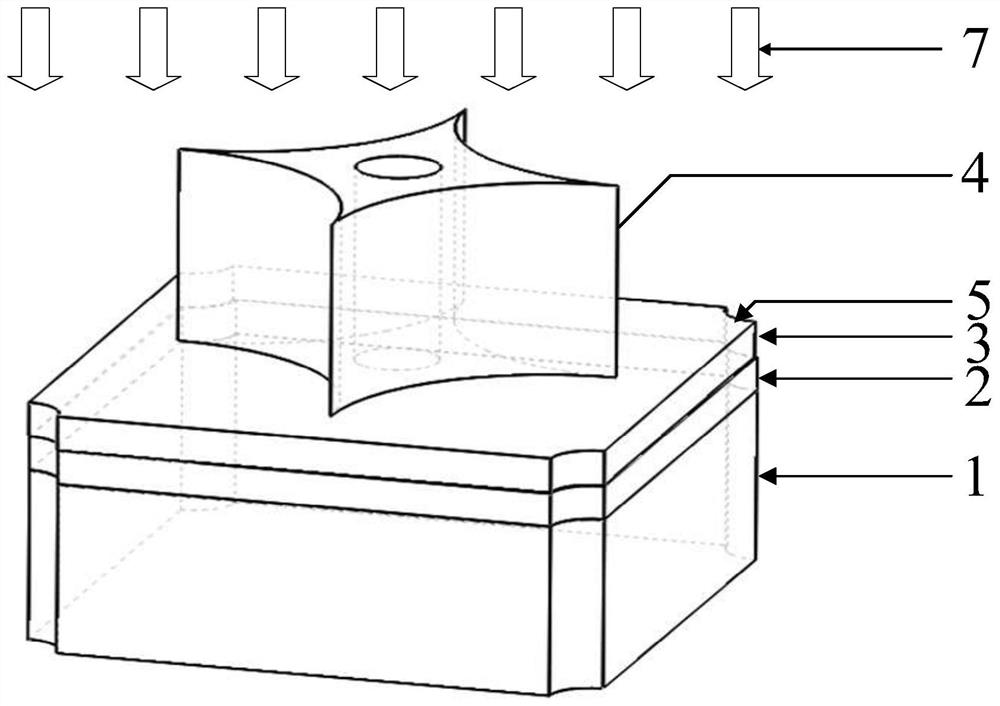

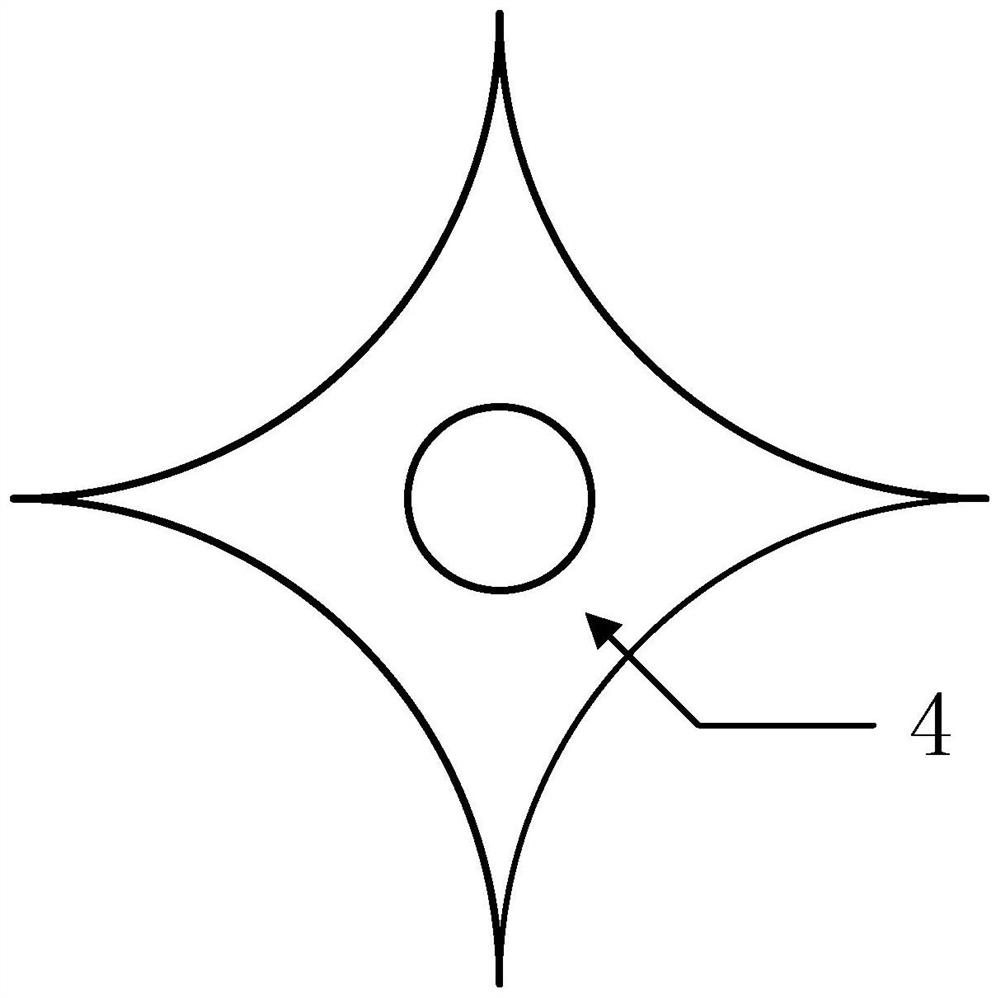

Embodiment 1

[0041] The bottom support plate 1 is made of aluminum oxide with a thickness of 1mm; the metal film 2 is made of titanium with a thickness of 240nm; the metal nano-curved four-pointed star-shaped prisms 4 with circular holes in the center are arranged in a square array 8, and the two phases The distance between the central axes of the adjacent metal nano-arc four-pointed star-shaped prism 4 is 330nm; the material of the metal nano-four-pointed star-shaped prism 4 is titanium, and the thickness of each metal nano-four-pointed star-shaped prism 4 is 170nm, and its cross section is the center Arc-sided four-pointed star with circular holes, wherein the arc-sided four-pointed star is surrounded by four arcs of the same shape, and the angle of each arc is 90°, the radius is 160nm, and the diameter of the central hole is 60nm; dielectric film The material of 3 is silicon dioxide, with a thickness of 40nm; at the center of each square 10 in the square array 8, there is a cylindrical h...

Embodiment 2

[0063] The bottom support plate 1 is made of aluminum oxide with a thickness of 1mm; the material of the metal film 2 is tungsten with a thickness of 300nm; the metal nano-curved four-pointed star-shaped prism 4 with a round hole in the center is arranged in a square array 8, and the two phases The distance between the central axes of the metal nano-curved four-pointed star-shaped prism 4 is 350nm; the material of the metal nano-curved four-pointed star-shaped prism 4 is tungsten, and the thickness of each metal nano-curved four-pointed star-shaped prism 4 is 190nm. The cross-section is an arc-sided four-pointed star with a circular hole in the center, wherein the arc-sided four-pointed star is surrounded by four arcs of the same shape, and the angle of each arc is 90°, the radius is 160nm, and the diameter of the central circular hole is 70nm The material of the dielectric film 3 uses titanium dioxide with a thickness of 50nm; at the center of each square 10 in the square arra...

Embodiment 3

[0065]The bottom support plate 1 is made of aluminum oxide, with a thickness of 4mm; the material of the metal film 2 is nickel, with a thickness of 260nm; the metal nano arc-edge four-pointed star-shaped prism 4 with a round hole in the center is arranged in a square array 8, and the two phases The distance between the central axes of the metal nano-curved four-pointed star-shaped prism 4 is 320nm; the material of the metal nano-curved four-pointed star-shaped prism 4 is nickel, and the thickness of each metal nano-curved four-pointed star-shaped prism 4 is 150nm. The cross-section is an arc-sided four-pointed star with a circular hole in the center, wherein the arc-sided four-pointed star is surrounded by four arcs of the same shape, and the angle of each arc is 90°, the radius is 140nm, and the diameter of the central circular hole is 50nm The material of the dielectric film 3 uses silicon dioxide, and the thickness is 35nm; the central position of each square 10 in the squa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com