Rod-like microstructure optical fiber

A microstructured optical fiber and rod-like technology, which is applied in cladding optical fibers, light guides, optics, etc., can solve problems such as the inability to use long-distance communication and the inability of microstructured cladding to Bragg diffraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following specific embodiments.

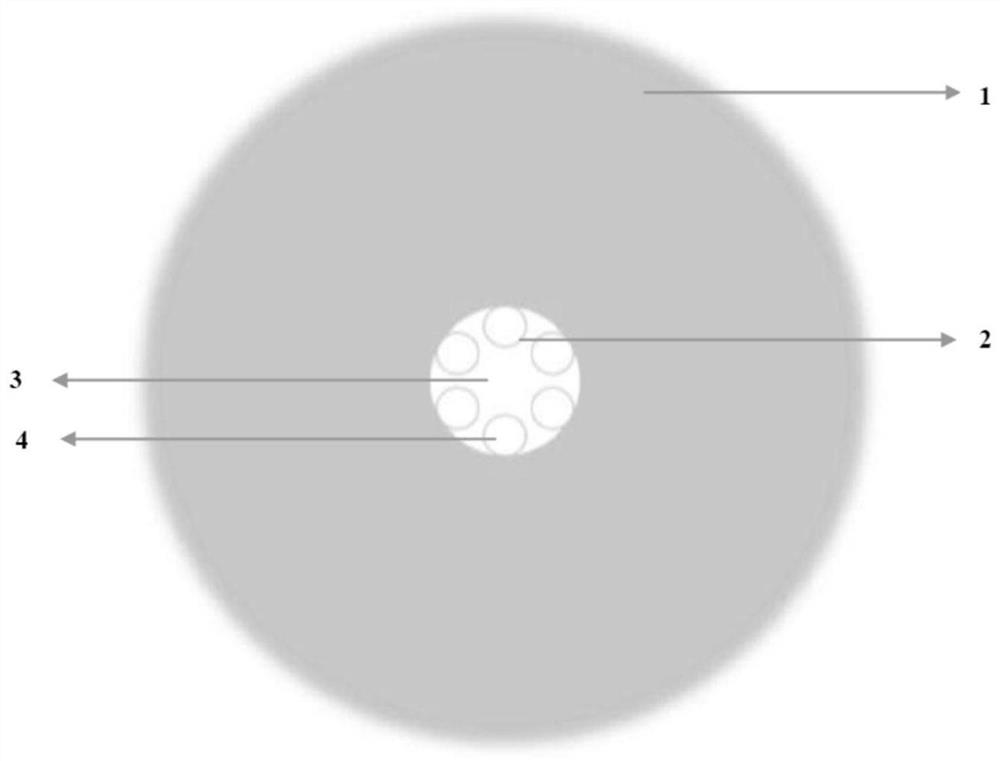

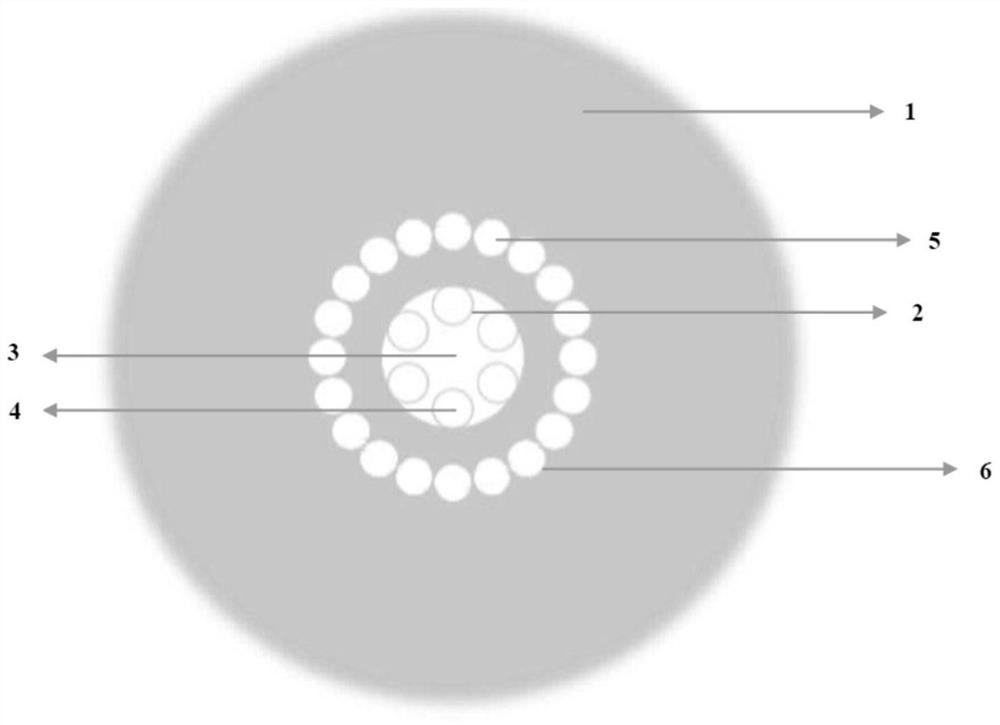

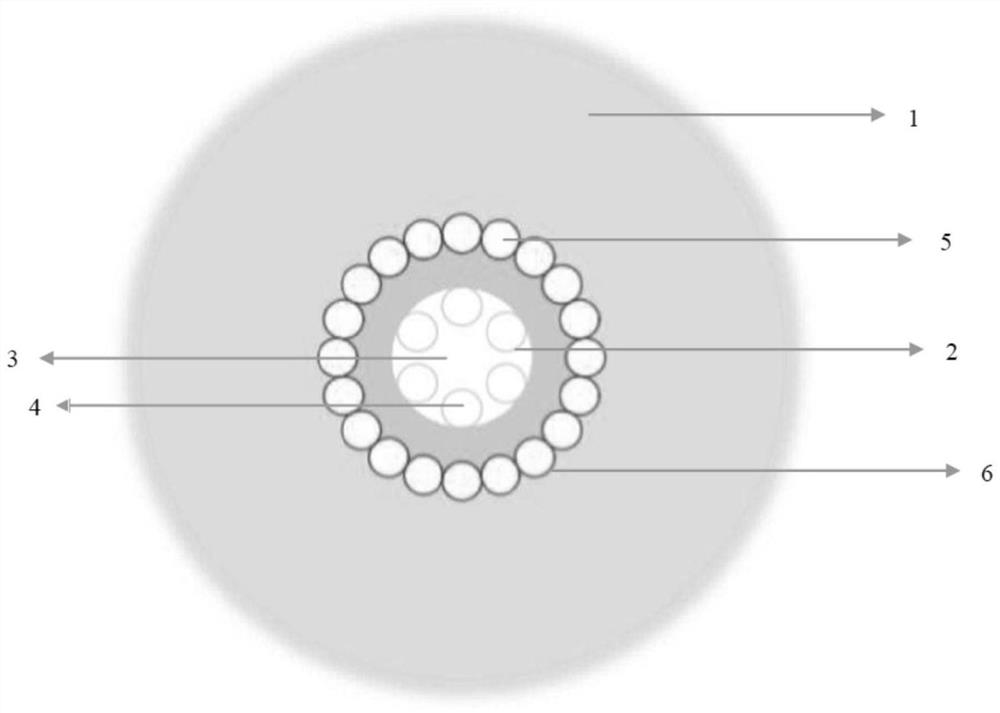

[0034] figure 1 , 2 , 3, 4, 5, and 6 show the schematic diagrams of the end face structures of Embodiments 1-6 of the rod-shaped microstructured optical fiber of the present invention. Their structures all include an outer cladding (1), an anti-resonant cladding (2), a core region (3) and an air region (4) in the anti-resonant cladding. The anti-resonant cladding is connected to the outer cladding. Among them, the refractive index of the anti-resonant cladding region (2) and the outer cladding region (1) is relatively high and equal, and the thickness of the outer cladding region (1) can reach the order of millimeters, so that the optical fiber is free from bending and external stress. Influenced perfect waveguide structure; the core region (3) is air. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com