Method for preparing micro-nano structure Prussian blue sodium battery positive electrode material through ultrasonic spray pyrolysis

A technology of Prussian blue and positive electrode materials, which is applied in the field of preparing micro-nano-structured sodium-ion battery positive electrode materials, can solve the problems of reduced tap density of electrode materials, unfavorable practical application, increased specific surface area of solid electrolyte membrane membrane, etc., and meets equipment requirements The effect of low, high tap density and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

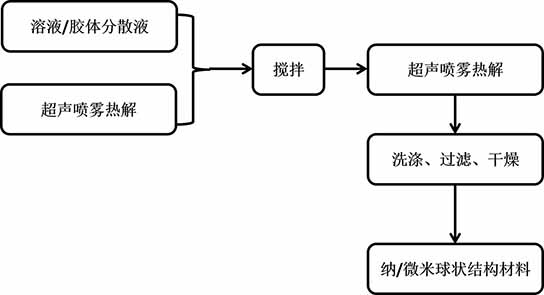

Method used

Image

Examples

Embodiment 1

[0029] In this example, uniformly mixed LiOH and electrode materials of equal mass are used for spray pyrolysis at 250°C. The specific operation steps are as follows:

[0030] (1) Precursor dispersion preparation: First prepare a certain concentration of CoCl 2 and Na 4 Fe(CN) 6 , and then slowly mix the two solutions. After a period of reaction, precipitation will occur. Wash the precipitation with water and ethanol three times, and then redisperse it in the aqueous solution.

[0031] (2) Ultrasonic spray pyrolysis: add an equal mass of LiOH to the dispersion prepared in step (1), put the suspension in an ultrasonic atomizer after dissolution, and then pass the atomized solution into the preheating Pyrolysis was performed in a tube furnace at 250°C, and powder samples were finally collected. Soak in deionized water for 1 hour, filter, then rinse with deionized water until neutral, and dry to obtain the required electrode material.

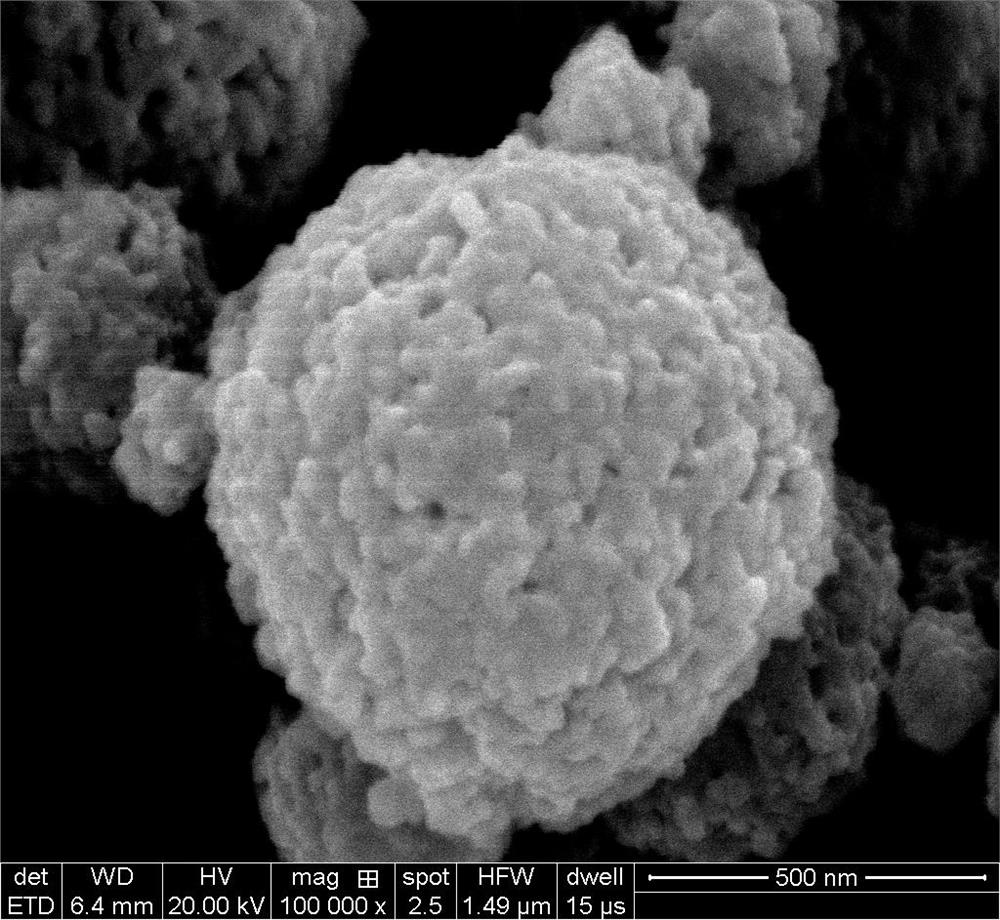

[0032] Adopt scanning electron microsco...

Embodiment 2

[0034] In this example, uniformly mixed KOH and electrode materials of equal mass are used for spray pyrolysis at 250°C. The specific operation steps are as follows:

[0035] (1) Precursor dispersion preparation: First prepare a certain concentration of CoCl 2 and Na 4 Fe(CN) 6 , and then slowly mix the two solutions. After a period of reaction, precipitation will occur. Wash the precipitation with water and ethanol three times, and then redisperse it in the aqueous solution.

[0036] (2) Ultrasonic spray pyrolysis: Add an equal mass of KOH to the dispersion prepared in step (1), put the suspension in an ultrasonic atomizer after dissolving, and then pass the atomized solution into the preheating Pyrolysis was performed in a tube furnace at 250°C, and powder samples were finally collected. Soak in deionized water for 1 hour, filter, then rinse with deionized water until neutral, and dry to obtain the required electrode material.

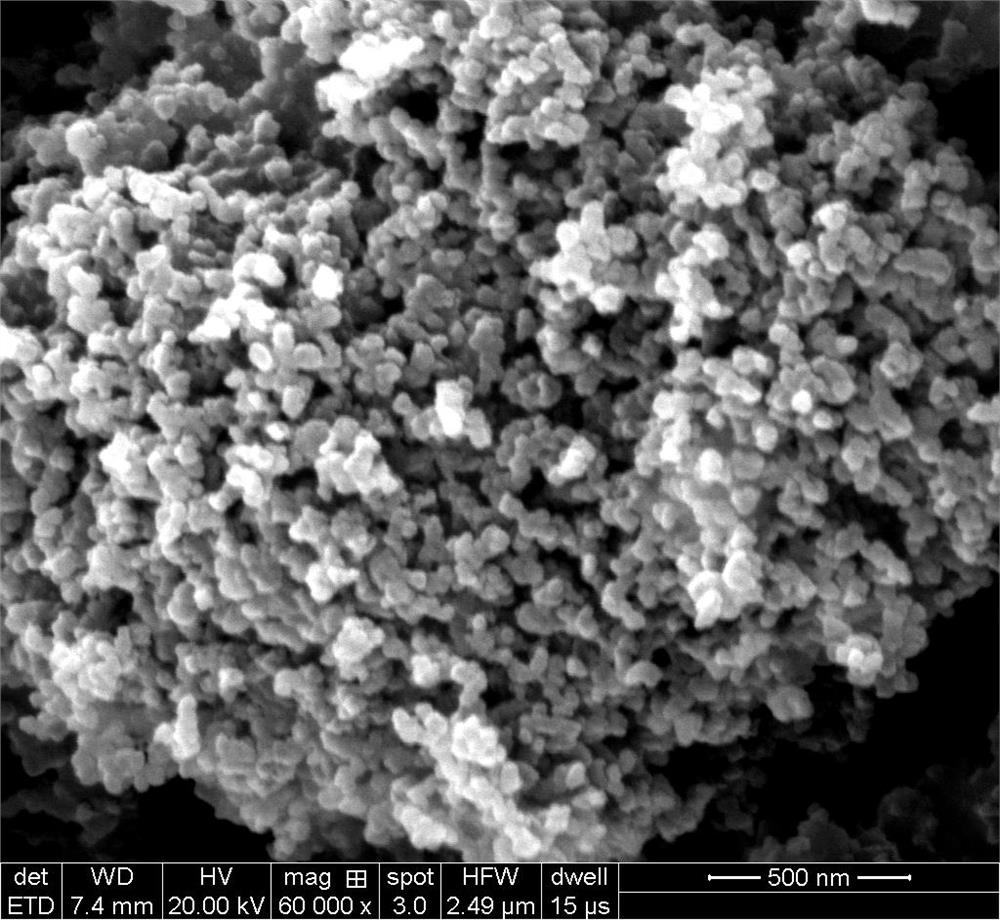

[0037] Adopt scanning electron microscope ...

Embodiment 3

[0039] This embodiment utilizes the Na of equal mass uniformly mixed 2 CO 3 And electrode material spray pyrolysis at 250 ℃, the specific operation steps are as follows:

[0040] (1) Precursor dispersion preparation: First prepare a certain concentration of CoCl 2 and Na 4 Fe(CN) 6 , and then slowly mix the two solutions. After a period of reaction, precipitation will occur. Wash the precipitation with water and ethanol three times, and then redisperse it in the aqueous solution.

[0041] (2) Ultrasonic spray pyrolysis: add an equal mass of Na to the dispersion prepared in step (1) 2 CO 3, after being dissolved, the suspension was placed in an ultrasonic atomizer, and then the atomized solution was passed into a tube furnace preheated to 250°C for pyrolysis, and finally the powder sample was collected. Soak in deionized water for 1 hour, filter, then rinse with deionized water until neutral, and dry to obtain the required electrode material.

[0042] Adopt scanning elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com