Modified pearlescent powder, preparation method thereof and cosmetics

A technology of pearlescent powder and cosmetics, which is applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc. It can solve the problems of pearlescent powders not shining enough, not easy to apply evenly, and poor makeup retention, so as to improve spreadability and high gloss , good makeup effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The present invention also provides a method for preparing the modified pearlescent powder, comprising: mixing the pearlescent powder, fluorine-containing silane coupling agent and lauroyl lysine powder, and heating to obtain the modified pearlescent powder.

[0038] Since the alkoxy group of the fluorine-containing silane coupling agent will be hydrolyzed to form silanol in the air, so, in one embodiment, the pearlescent powder and lauroyl lysine powder are mixed first, and then the fluorine-containing silane coupling agent is added agent, to avoid premature hydrolysis of the fluorine-containing silane coupling agent and connect to the surface of the pearlescent powder, affecting the coating effect of the lauroyl lysine powder on the surface of the pearlescent powder.

[0039] At the same time, the lauroyl lysine powder is randomly coated on the surface of the pearlescent powder, and then the fluorine-containing silane coupling agent reacts with the uncoated surface, an...

Embodiment 1

[0055] Mix 30g lauryl lysine powder with lamellar structure and 1kg pearlescent powder (10μm-60μm, silvery white, mica substrate, titanium dioxide cover layer), and then add 10g perfluorooctyl triethoxy The base silane was evenly mixed, heated to 110° C. and kept for 2 hours to obtain a modified pearlescent powder.

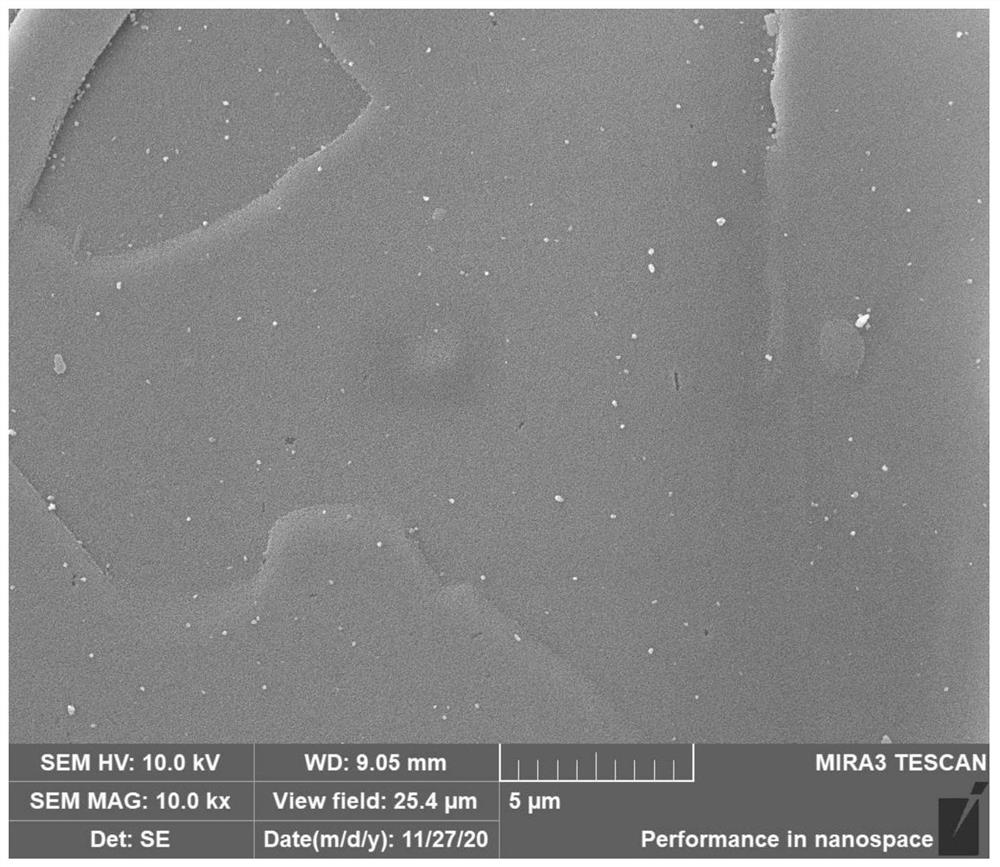

[0056] like figure 1 As shown, in the modified pearlescent powder obtained in this example, lauroyl lysine powder with a lamellar structure covers the surface of the pearlescent powder. In addition, in the modified pearlescent powder, the fluorine-containing silane coupling agent is connected to the pearlescent powder through a covalent bond, and part of the fluorine-containing silane coupling agent associates with each other and forms a network-like film, in which the lamellar laurel The acyllysine powder and the fluorine-containing silane coupling agent are interlacedly distributed.

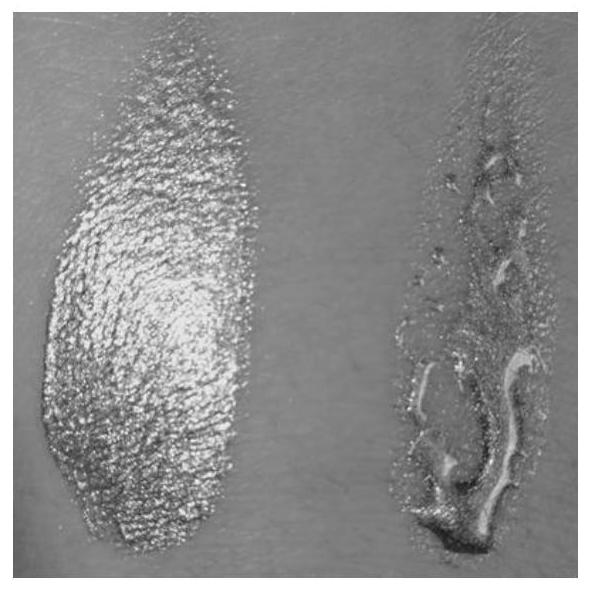

[0057] The pearlescent powder of this embodiment and the modified pearlescen...

Embodiment 2

[0061] The only difference between Example 2 and Example 1 is that the particle size of the pearlescent powder in Example 2 is 30 μm-150 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com