Transformation method for sludge in-situ reduction of sewage treatment plant

A technology for sludge in-situ reduction and sewage treatment plants, applied in water/sludge/sewage treatment, sludge treatment, sludge treatment, etc., can solve the problem of high surplus sludge production, achieve low input cost, reduce The effect of low operating cost and difficulty of reconstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

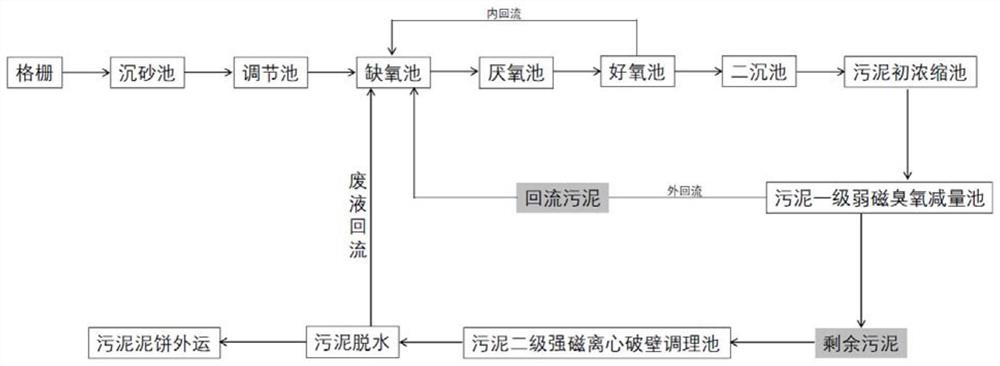

[0023] A transformation method applied to the in-situ reduction of sludge in traditional sewage treatment plants, figure 1 Be the technological process schematic diagram of the present invention, in traditional municipal sewage treatment process (as A 2 / O, but not limited to A 2 / O process), after the sludge in the initial concentration tank passes through the first-level weak magnetic ozone reduction tank, a part of the sludge enters the anoxic tank as return sludge, and the sludge ozone in the first-level weak magnetic ozone reduction tank is micro-nano When the ozone entrainment rate of the bubbles reaches 50%, and the ozone concentration in the water reaches 12mg / L, it enters A 2 / O system, the ozone micro-nano bubble adopts the conventional ozone generator and the micro-nano bubble generating device; the other part of the sludge enters the second-level strong magnetic centrifugal wall-breaking conditioning tank as the remaining sludge, and the ozone is reduced in the fi...

Embodiment 2

[0028] A transformation method applied to the in-situ reduction of sludge in traditional sewage treatment plants, figure 1 Be the technological process schematic diagram of the present invention, in traditional municipal sewage treatment process (as A 2 / O, but not limited to A 2 / O process), after the sludge in the initial concentration tank passes through the first-level weak magnetic ozone reduction tank, a part of the sludge enters the anoxic tank as return sludge, and the sludge ozone in the first-level weak magnetic ozone reduction tank is micro-nano When the ozone entrainment rate of the bubbles reaches 50%, and the ozone concentration in the water reaches 15mg / L, it enters A 2 / O system, the ozone micro-nano bubble adopts the conventional ozone generator and the micro-nano bubble generating device; the other part of the sludge enters the second-level strong magnetic centrifugal wall-breaking conditioning tank as the remaining sludge, and the ozone is reduced in the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com