A kind of ceramic material and its preparation method and application

A technology of ceramic materials and ceramic capacitors, applied in the field of materials, can solve problems such as low breakdown field strength, low energy storage density, and limited applications, and achieve the effects of good stability, high energy storage density, and huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0077] The preparation method of ceramic material of the present invention, comprises the steps:

[0078] (1) According to the chemical formula Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 Weigh the analytically pure BaCO of stoichiometric ratio 3 , CaCO 3 , ZrO 2 and TiO 2 Perform batching, then ball mill for 10h to 12h at a speed of 300r / min to 400r / min for mixing, and calcined at 1100°C to 1200°C for 4h to 6h to obtain Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 Powder, Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 The sieve residue of the powder passing through the 120 mesh sieve is ≤5%. Among them, the ball mill adopts wet ball milling, with absolute ethanol as the medium, zirconia as the grinding ball, and the mass ratio of absolute ethanol, zirconium ball and powder is 2:(1~1.5):1.

[0079] (2) According to the chemical formula Sr 0.7 Bi 0.2 TiO 3 Weigh the analytically pure SrCO of stoichiometric ratio 3 、 Bi 2 o 3 and TiO 2 Dosing, then ball milling at 300r / min-400r / min for 1...

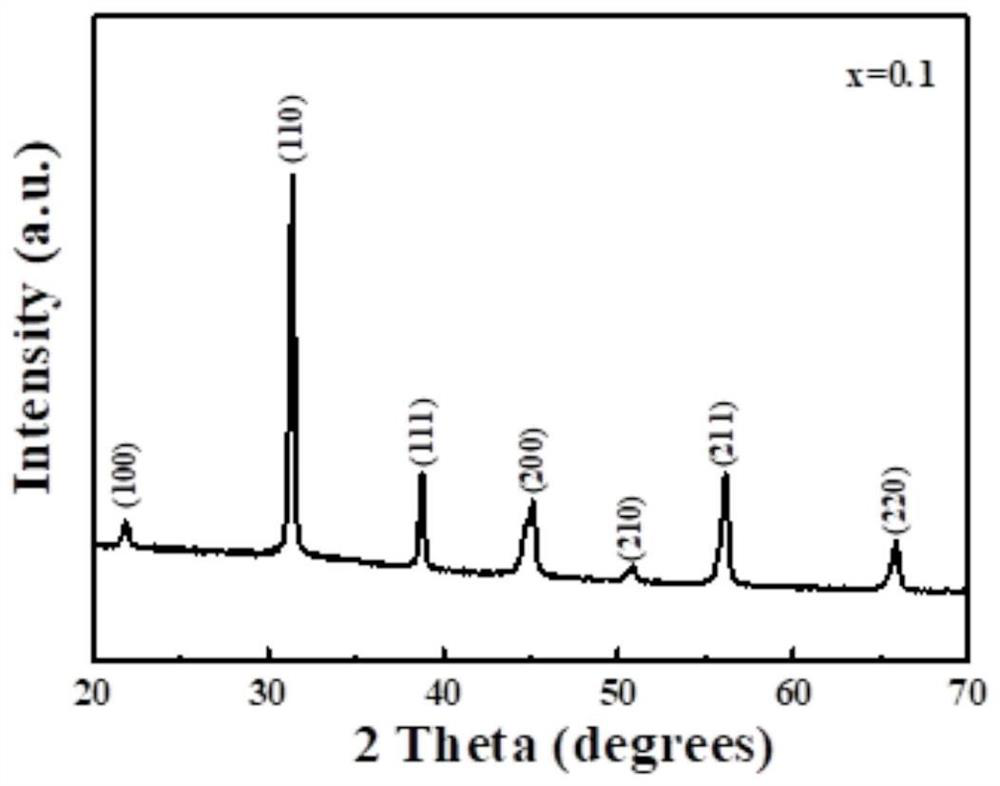

Embodiment 1

[0089] In the present embodiment, shown in the chemical formula of ceramic material: 0.9(Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 )0.1(Sr 0.7 Bi 0.2 TiO 3 ), prepared according to the following steps:

[0090] (1) According to the chemical formula Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 Weigh out the stoichiometric BaCO 3 , CaCO 3 , ZrO 2 and TiO 2 Carry out batching, then ball mill at 300r / min for 10h for mixing, calcined at 1100°C for 4h, and pass through a 120-mesh sieve after crushing to obtain Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 Powder.

[0091] (2) According to the chemical formula Sr 0.7 Bi 0.2 TiO 3 Weigh out the stoichiometric ratio of SrCO 3 、 Bi 2 o 3 and TiO 2 Perform batching, then ball mill for 12 hours at a speed of 350r / min for mixing, calcined at 900°C for 4 hours, and pass through a 120-mesh sieve after crushing to obtain Sr 0.7 Bi 0.2 TiO 3 Powder.

[0092] (3) The powders of steps (1) and (2) are according to chemical formula 0.9 (Ba 0.85 C...

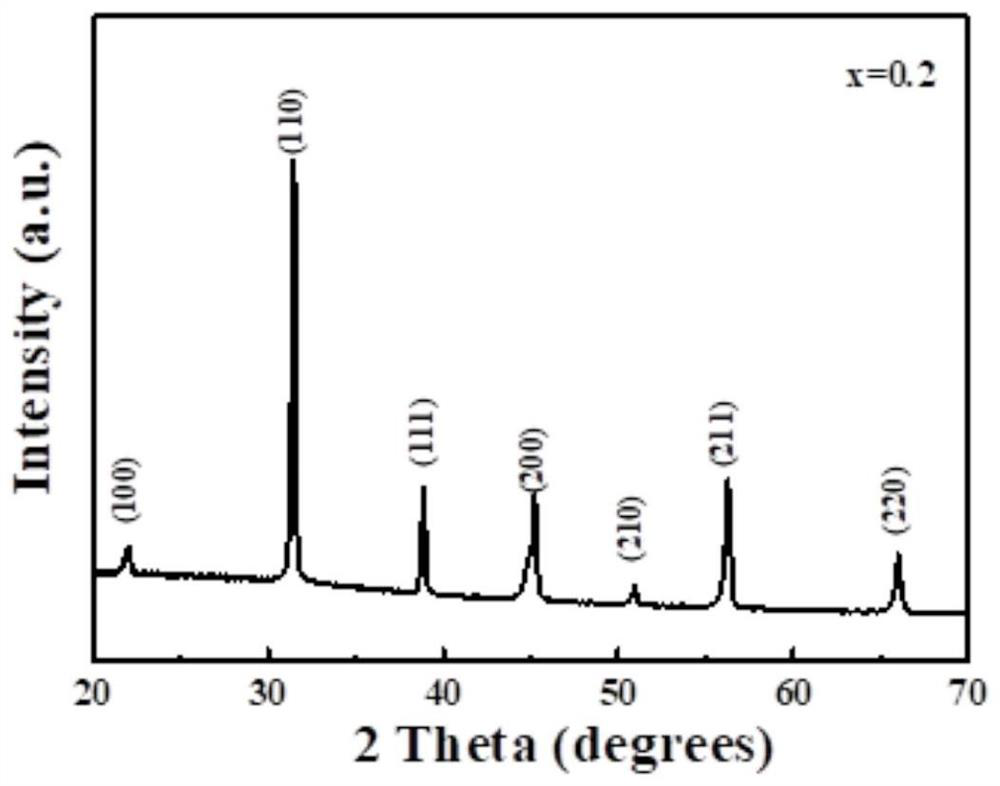

Embodiment 2

[0102] In the present embodiment, shown in the chemical formula of ceramic material: 0.8 (Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 )0.2(Sr 0.7 Bi 0.2 TiO 3 ), prepared according to the following steps:

[0103] (1) According to the chemical formula Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 Weigh out the stoichiometric BaCO 3 , CaCO 3 , ZrO 2 and TiO 2 Carry out batching, then ball mill at 320r / min for 11h for mixing, calcined at 1100°C for 5h, and pass through a 120-mesh sieve after crushing to obtain Ba 0.85 Ca 0.15 Zr 0.1 Ti 0.9 o 3 Powder.

[0104] (2) According to the chemical formula Sr 0.7 Bi 0.2 TiO 3 Weigh out the stoichiometric ratio of SrCO 3 、 Bi 2 o 3 and TiO 2 Perform batching, then ball mill for 11 hours at a rotational speed of 320r / min for mixing, calcined at 960°C for 5 hours, and pass through a 120-mesh sieve after crushing to obtain Sr 0.7 Bi 0.2 TiO 3 Powder.

[0105] (3) The powder of steps (1) and (2) is according to chemical formula 0.8 (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| energy density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com