Production process for producing plasticizer from PTA oxidation residues

A production process and plasticizer technology, which is applied in the production process field of PTA oxidation residue to produce plasticizer, can solve the problems of single reaction product, low raw material utilization rate, low production efficiency, etc., and achieve reduced reaction difficulty and good cooling effect , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

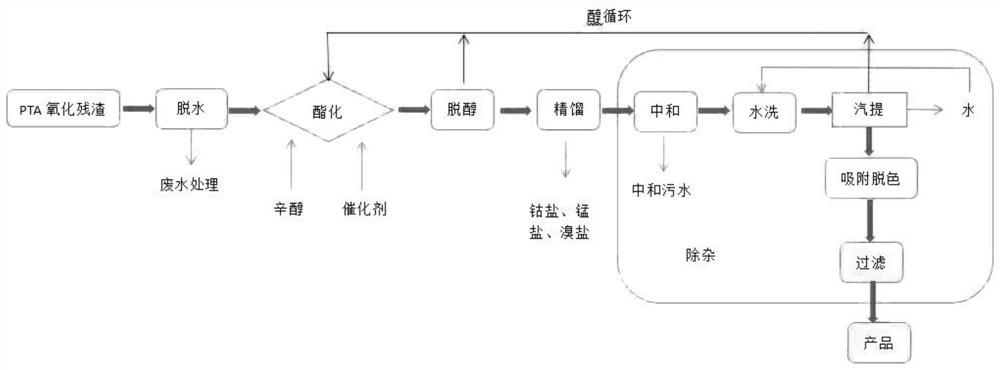

Method used

Image

Examples

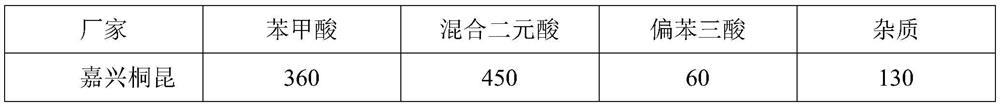

Embodiment 1

[0061] Take Jiaxing Tongkun PTA oxidation residue 1000g (dry basis) into the reactor, add 2001g of octanol, start heating and stirring. When the temperature of the material rises to 184°C, add 3.45g of tetrabutyl titanate catalyst, at this time, the octanol is refluxed with water, wait for the temperature in the kettle to rise to about 220°C and at the same time no water drops are extracted, which is regarded as the end point of the esterification reaction. When it is detected that the acid value of the esterification solution is below 0.5, the esterification reaction is over. When the temperature of the esterification liquid is lowered to 90°C, start to filter to obtain a transparent esterification liquid, and start to enter the rectification step.

[0062] Pour the transparent esterification liquid into the still of the rectification tower. When the vacuum at the top of the tower reaches 0.15kpa, heat the still. When the temperature at the top of the tower rises and stabiliz...

Embodiment 2

[0066] Take Shanghai Yadong PTA oxidation residue 1000g (dry basis) into the reactor, add octanol 2001g, start heating and stirring. When the temperature of the material rises to 184°C, add 3.45g of tetrabutyl titanate catalyst, at this time, the octanol is refluxed with water, wait for the temperature in the kettle to rise to about 220°C and at the same time no water drops are extracted, which is regarded as the end point of the esterification reaction. When it is detected that the acid value of the esterification solution is below 0.5, the esterification reaction is over. When the temperature of the esterification liquid is lowered to 90°C, start to filter to obtain a transparent esterification liquid, and start to enter the rectification step.

[0067] Pour the transparent esterification liquid into the still of the rectification tower. When the vacuum at the top of the tower reaches 0.15kpa, heat the still. When the temperature at the top of the tower rises and stabilizes ...

Embodiment 3

[0072] Take Jiangyin Hailun PTA oxidation residue 1000g (dry basis) into the reactor, add 2001g of octanol, start heating and stirring. When the temperature of the material rises to 184°C, add 3.45g of tetrabutyl titanate catalyst, at this time, the octanol is refluxed with water, wait for the temperature in the kettle to rise to about 220°C and at the same time no water drops are extracted, which is regarded as the end point of the esterification reaction. When it is detected that the acid value of the esterification solution is below 0.5, the esterification reaction is over. When the temperature of the esterification liquid is lowered to 90°C, start to filter to obtain a transparent esterification liquid, and start to enter the rectification step.

[0073] Pour the transparent esterification liquid into the still of the rectification tower. When the vacuum at the top of the tower reaches 0.15kpa, heat the still. When the temperature at the top of the tower rises and stabiliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com