A high-performance 3D printed piezoelectric part and its preparation method

A 3D printing, high-performance technology, applied in the field of 3D printing, can solve problems such as low efficiency, high energy consumption, and low performance of parts, and achieve the effects of avoiding oxidative degradation, excellent comprehensive performance, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

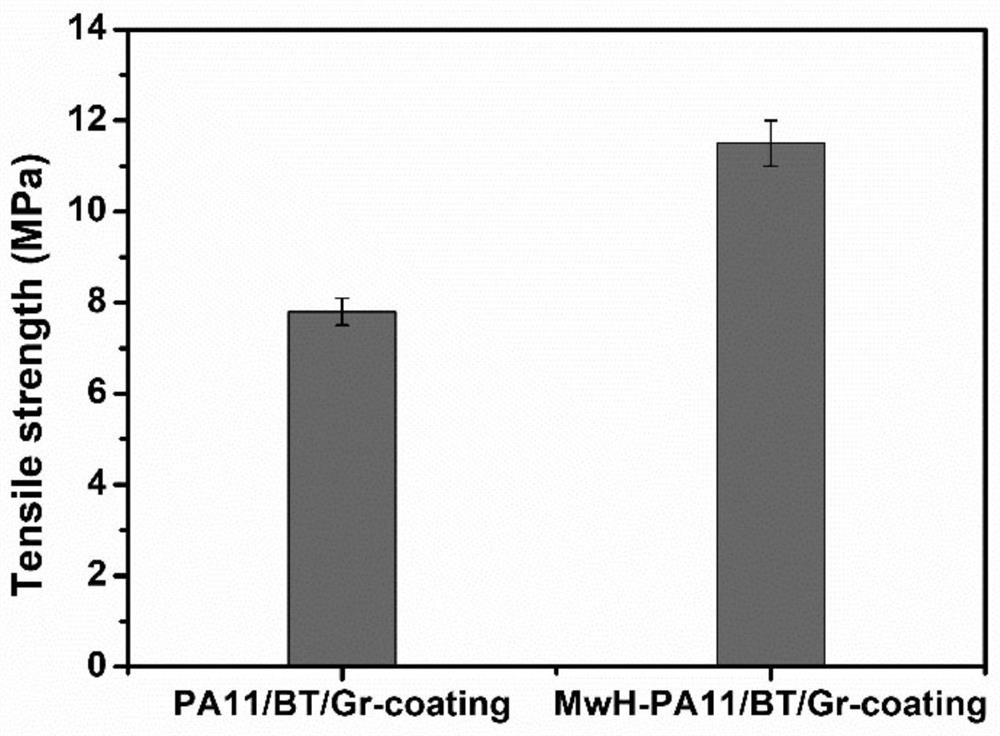

[0036] A high-performance 3D printing piezoelectric part, the preparation method of which comprises the following steps:

[0037] (1) 200g of PA11 pellets and 300g of BaTiO with an average particle size of 0.5μm 3 The powder is mixed evenly and added to the solid-phase shearing milling equipment. During the milling process, the temperature of the cooling cycle water is controlled at 30°C, the milling pressure is 20MPa, the milling speed is 35rpm, and the milling times are 10 times. Powder, sieve it, and select the composite material powder with a particle size within the range of 300 meshes, which is PA11 / BaTiO 3 Piezoelectric composite powder;

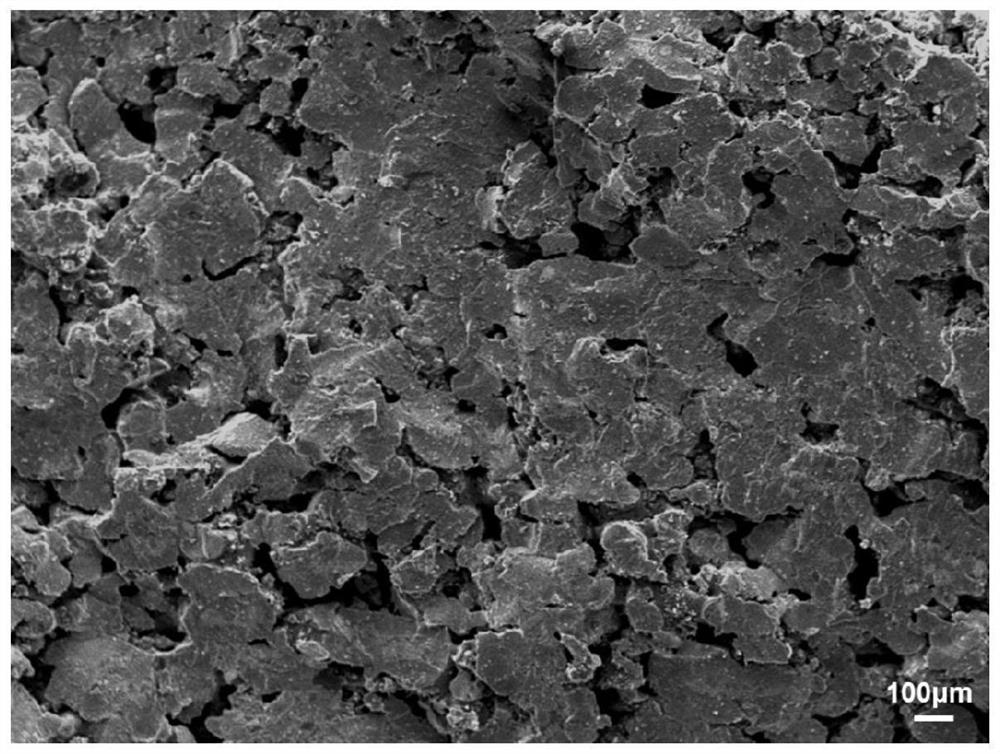

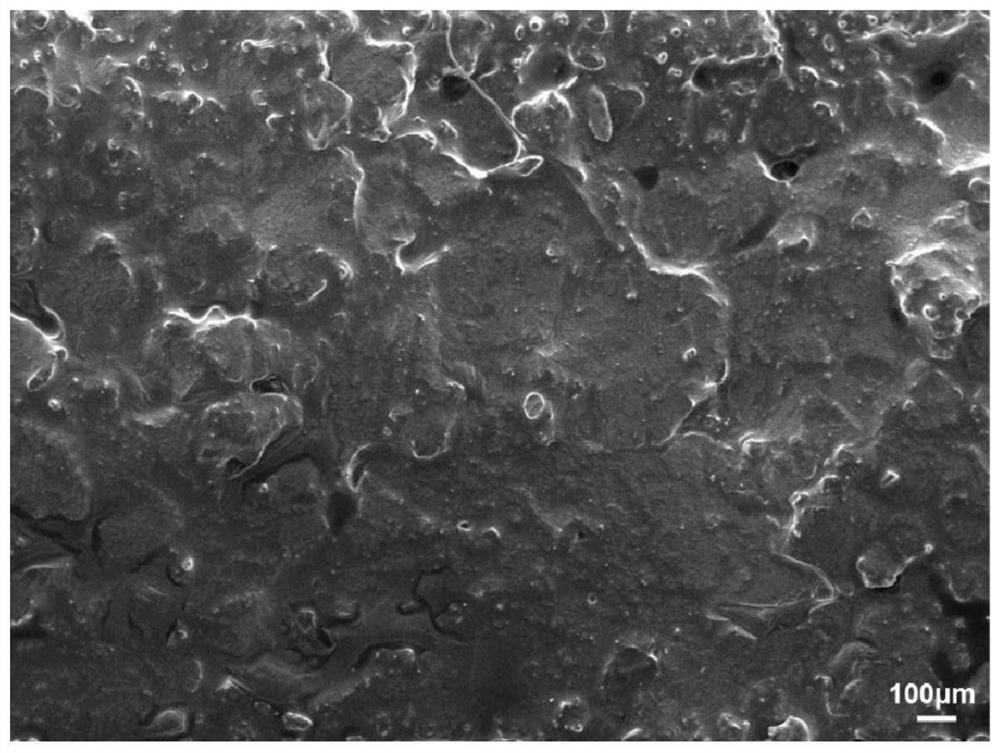

[0038] (2) PA11 / BaTiO in step (1) 3The surface of the piezoelectric composite powder is coated with graphene wave-absorbing material. The specific coating operation is as follows: add 2 g of graphene into 1 L of ethanol solution, and carry out ultrasonic dispersion for 1 h at an ultrasonic power of 800 W to obtain a stable graphene ...

Embodiment 2

[0041] A high-performance 3D printing piezoelectric part, the preparation method of which comprises the following steps:

[0042] (1) 100g of PVDF pellets and 300g of BaTiO with an average particle size of 50 μm 3 The powder is mixed evenly and added to the solid phase shearing milling equipment. During the milling process, the temperature of the cooling circulation water is controlled at 5°C, the milling pressure is 50MPa, the milling speed is 100rpm, and the number of milling times is 20 times. Powder, sieve it, and select the composite material powder with a particle size within the range of 800 meshes, which is PVDF / BaTiO 3 Piezoelectric composite powder;

[0043] (2) PVDF / BaTiO in step (1) 3 The surface of the piezoelectric composite powder is coated with graphene absorbing material. The specific coating operation is as follows: add 2.5g graphene into 1L ethanol solution, and carry out ultrasonic dispersion for 1 hour under the ultrasonic power of 800W to obtain a stabl...

Embodiment 3

[0046] A high-performance 3D printing piezoelectric part, the preparation method of which comprises the following steps:

[0047] (1) Mix 200g of PA11 pellets and 100g of lead zirconate titanate powder with an average particle size of 0.3μm and add them to the solid phase shearing milling equipment. It is 30MPa, the grinding speed is 80rpm, and the number of grinding times is 15 times. The composite powder is obtained by grinding, which is sieved, and the composite material powder with a particle size within the range of 500 meshes is selected, which is PA11 / lead zirconate titanate pressed Electric composite powder;

[0048] (2) The surface of the PA11 / lead zirconate titanate piezoelectric composite powder in step (1) is coated with CNTs wave-absorbing material. The specific coating operation is: add 3.0g of CNTs to 1L ethanol solution, and under the ultrasonic power of 800W Ultrasonic dispersion was performed for 1 hour to obtain a stable CNTs dispersion; 300 g of the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com