Imported flaxseed impurity biological inactivation treatment device and inactivation process

A biological inactivation and treatment device technology, applied in the direction of fat generation, fat oil/fat production, heating, etc., can solve the problems that do not meet the safety and environmental protection concepts of oil plant enterprises, and achieve pollution prevention, simple inactivation process, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

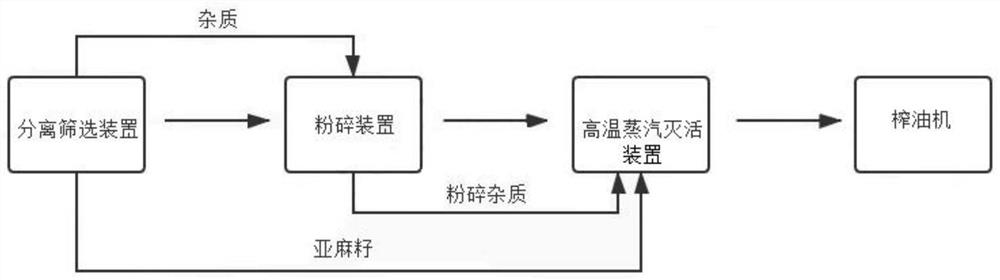

[0024] An imported linseed impurity biological inactivation treatment device, including a separation and screening device, a crushing device, a steam inactivation device and an oil press connected in sequence;

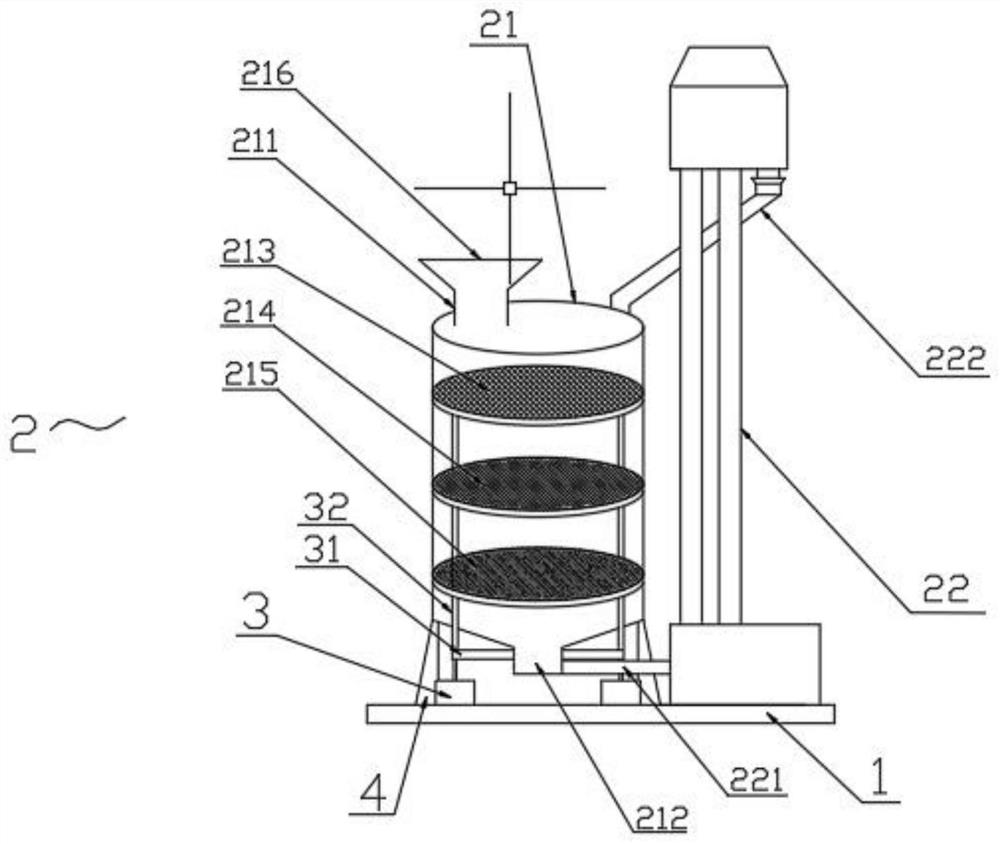

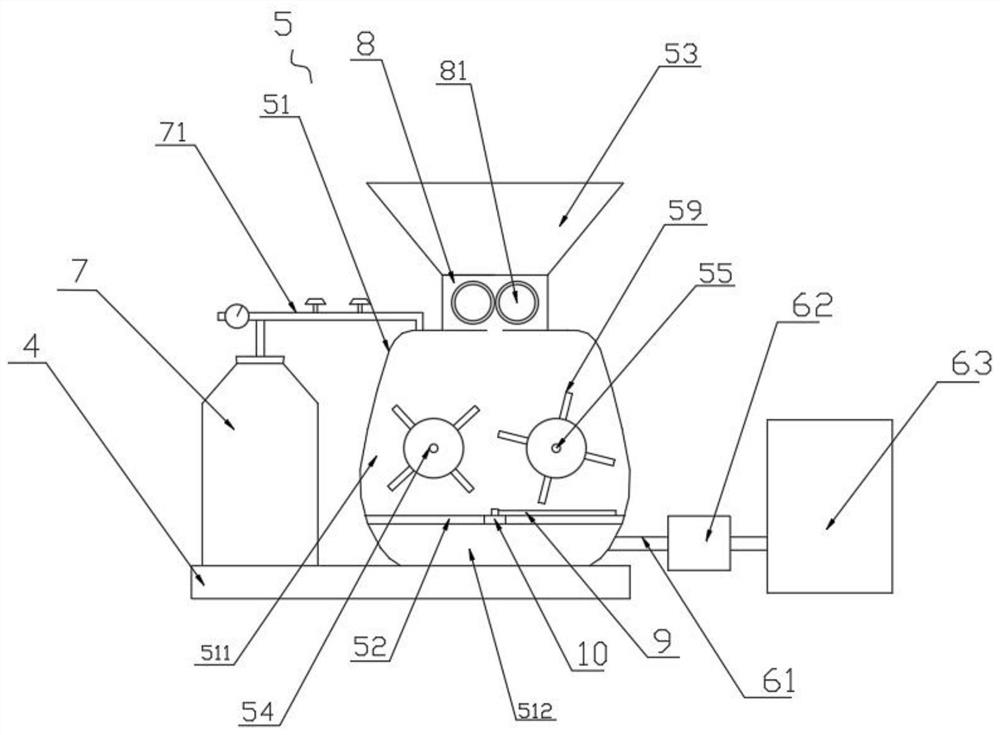

[0025] The invention provides a flaxseed impurity separation and screening device, comprising a first base 1 and a screening mechanism 2 arranged on the top of the first base 1; two vibration motors 3 are arranged above the first base 1, and the two A vibrating plate 31 is connected between the output shafts of the vibrating motor 3, and vibrating rods 32 are installed on the left and right sides above the vibrating plate 31; the screening mechanism 2 includes a screening tank 21 and a lifting mechanism 22 arranged on the outside of the screening tank 21 The top of the screening tank 21 is provided with a feed inlet 211, and the bottom is provided with a tapered discharge opening 212; the inside of the screening tank 21 is provided with a large mesh sieve plate 213 and ...

Embodiment 2

[0033] A biological inactivation treatment process for imported linseed impurities, characterized in that it comprises the following steps:

[0034] (1) Use a separation and screening device to sieve the impurities in the flaxseed, and then send the impurities to a crushing device for crushing to a particle size≦2mm to obtain crushed impurities;

[0035] (2) After the impurity-removed linseed is mixed with the pulverized impurities, it is passed into a high-temperature steam fire extinguishing device for inactivation to obtain an inactivated material; wherein, the temperature of the high-temperature steam is 105° C.;

[0036] (3) Send the inactivated material into the seed frying machine for frying, and then enter the oil press for pressing to obtain linseed crude oil and linseed pressed cake.

Embodiment 3

[0038] A biological inactivation treatment process for imported linseed impurities, characterized in that it comprises the following steps:

[0039] (1) Use a separation and screening device to sieve out the impurities in the flaxseed, then send the impurities into the crushing device for crushing to a particle size of ≦2mm, assist in feeding pulse nitrogen during the crushing process, and the ventilation frequency is 5 times / second, to obtain crushed impurities;

[0040] (2) After the impurity-removed linseed is mixed with the pulverized impurities, it is passed into a high-temperature steam fire extinguishing device for inactivation to obtain an inactivated material; wherein, the temperature of the high-temperature steam is 115° C.;

[0041] (3) Send the inactivated material into the seed frying machine for frying, and then enter the oil press for pressing to obtain linseed crude oil and linseed pressed cake.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com