Tungsten and molybdenum separation method

A separation method and tungsten and molybdenum technology, applied in the direction of improving process efficiency, can solve the problems of high molybdenum content and increasing the cost of molybdenum removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

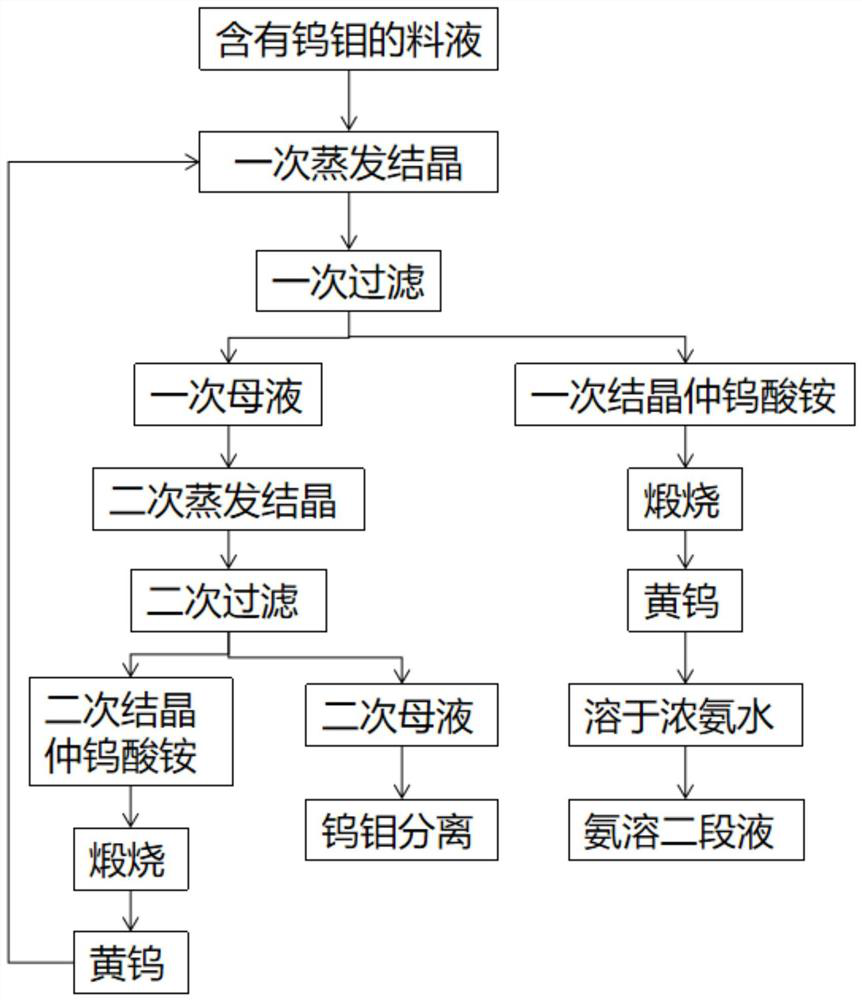

Method used

Image

Examples

Embodiment 1

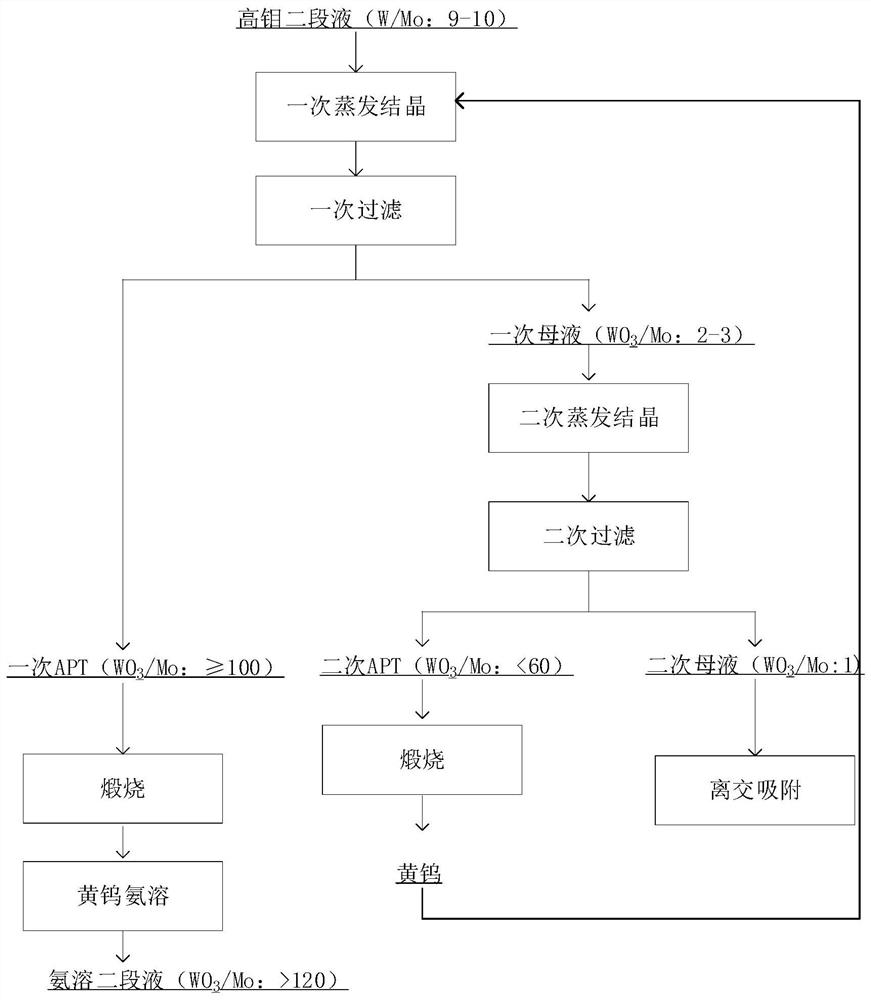

[0049] (1) 7.5m 3 The high molybdenum second-stage liquid (WO 3 : 215.1g / L, Mo: 16.5g / L), carry out one evaporative crystallization, and obtain one mother liquor and one crystalline ammonium paratungstate (APT) after one filtration. In the process of one evaporative crystallization, the vapor pressure is 0.25MPa, the vacuum pressure is -0.025MPa, and the evaporation to the final liquid level is about 4m 3 , the final mother liquor volume is 0.53 of the total volume. Filtration by filter and sampling analysis to obtain WO in the primary mother liquor 3 : 75.2g / L, Mo: 30.2g / L, after alkali dissolution, WO in APT was obtained as a crystal 3 / Mo:145.

[0050] (2) subjecting the primary mother liquor to secondary evaporation and crystallization to obtain secondary mother liquor and secondary crystalline ammonium paratungstate (APT). After alkali dissolution, WO in APT is obtained by secondary crystallization 3 / Mo: 45, the secondary crystallization APT is calcined with 100kg ...

Embodiment 2

[0053] (1) 7.5m 3 The high molybdenum second-stage liquid (WO 3 : 210.1g / L, Mo: 12.5g / L), carry out one evaporative crystallization, and obtain one mother liquor and one crystal ammonium paratungstate (APT) after one filtration. In the process of one evaporative crystallization, the vapor pressure is 0.3MPa, the vacuum pressure is -0.03MPa, and the evaporation to the final liquid level is about 3.8m 3 , the final mother liquor volume is 0.51 of the total volume. Filtration by filter and sampling analysis to obtain WO in the primary mother liquor 3 : 65.2g / L, Mo: 25.1g / L, after being dissolved in alkali, a crystal of WO in APT was obtained 3 / Mo:135.

[0054] (2) subjecting the primary mother liquor to secondary evaporation and crystallization to obtain secondary mother liquor and secondary crystalline ammonium paratungstate (APT). After alkali dissolution, WO in APT is obtained by secondary crystallization 3 / Mo: 55, the secondary crystallization APT is calcined with 120...

Embodiment 3

[0057] (1) 7.5m 3 The high molybdenum second-stage liquid (WO 3 : 209.1g / L, Mo: 11.5g / L), carry out one evaporative crystallization, and obtain one mother liquor and one crystal ammonium paratungstate (APT) after one filtration. In the process of one evaporative crystallization, the vapor pressure is 0.28MPa, the vacuum pressure is -0.035MPa, and the evaporation to the final liquid level is about 4.5m 3 , the final mother liquor volume is 0.6 of the total volume. Filtration by filter and sampling analysis to obtain WO in the primary mother liquor 3 : 66.3g / L, Mo: 28.6g / L, after alkali dissolution, WO in APT was obtained as a crystal 3 / Mo:130.

[0058] (2) subject the primary mother liquor to secondary evaporative crystallization to obtain secondary mother liquor and secondary crystalline ammonium paratungstate (APT), and obtain WO in secondary crystalline APT after alkali dissolution 3 / Mo: 46, the secondary crystallization APT is calcined with 90kg of primary mother liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com