Preparation method of low-temperature-resistant stretchable solid-liquid double-phase CuGa2-GaInSn conductive thin film

A conductive film, cuga2-gainsn technology, applied in ion implantation plating, metal material coating process, coating and other directions, to achieve excellent application prospects, improve low temperature phase stability, reduce the effect of solidification temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

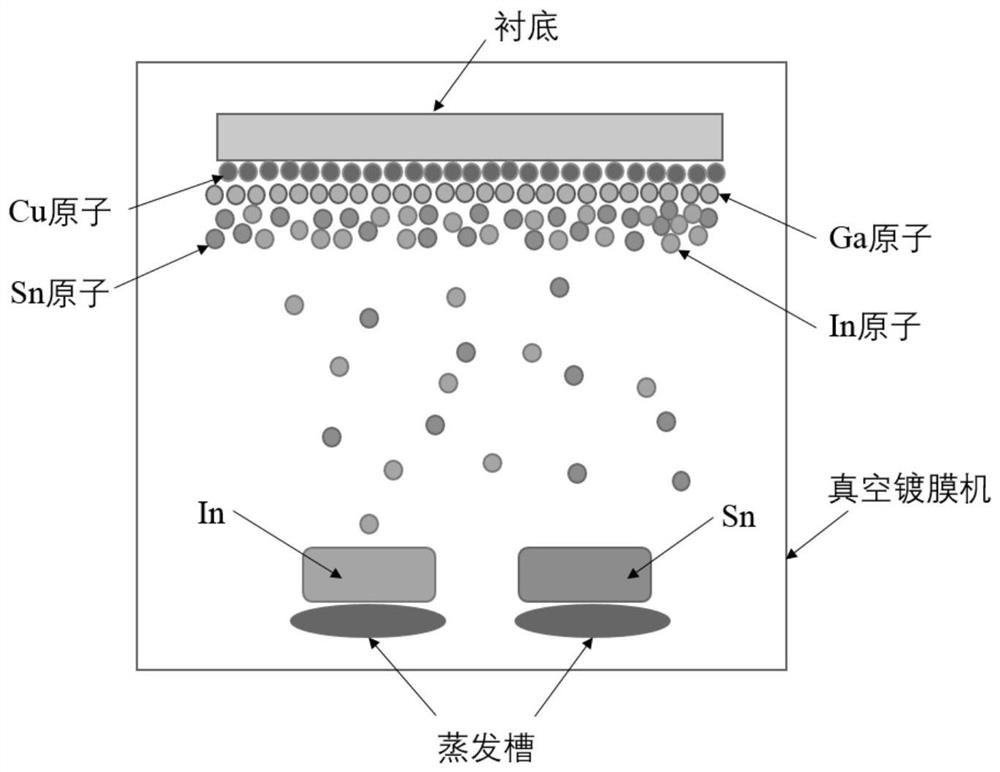

[0024] A Stretchable Solid-liquid Dual Phase CuGa with Low Temperature Resistance 2 -The preparation method of GaInSn conductive thin film, comprises following preparation steps:

[0025] (1) Use a flexible high temperature resistant (stable at 250°C) polymer film as the substrate, such as silicone rubber (PDMS), polyimide (PI), and use plasma treatment and surface mercaptolation on the substrate ,stand-by.

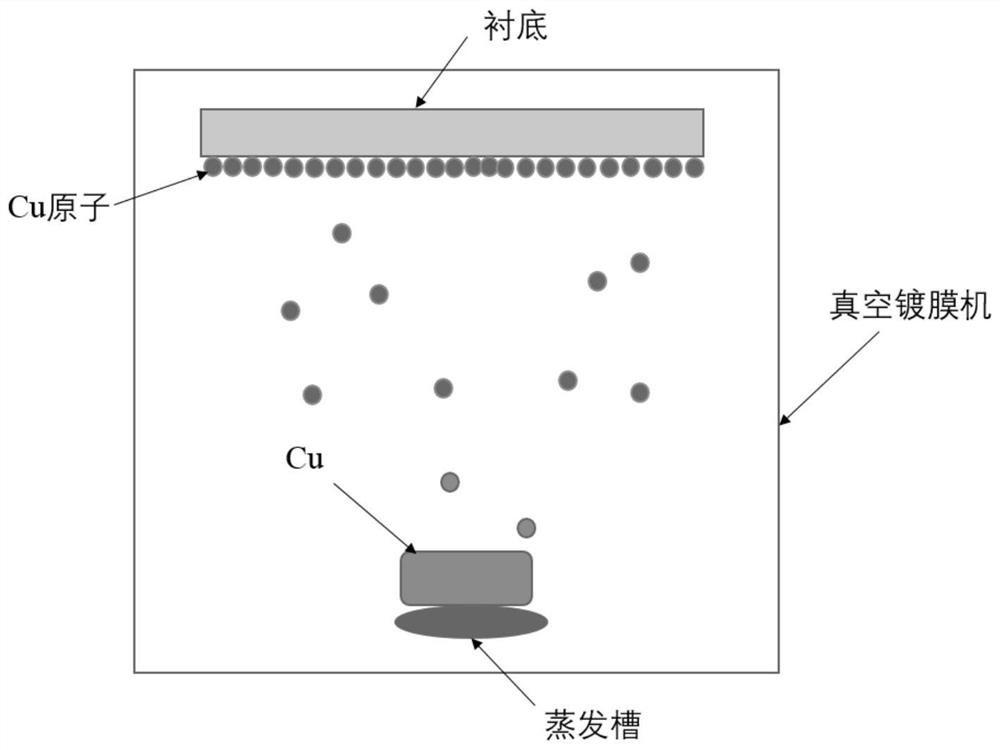

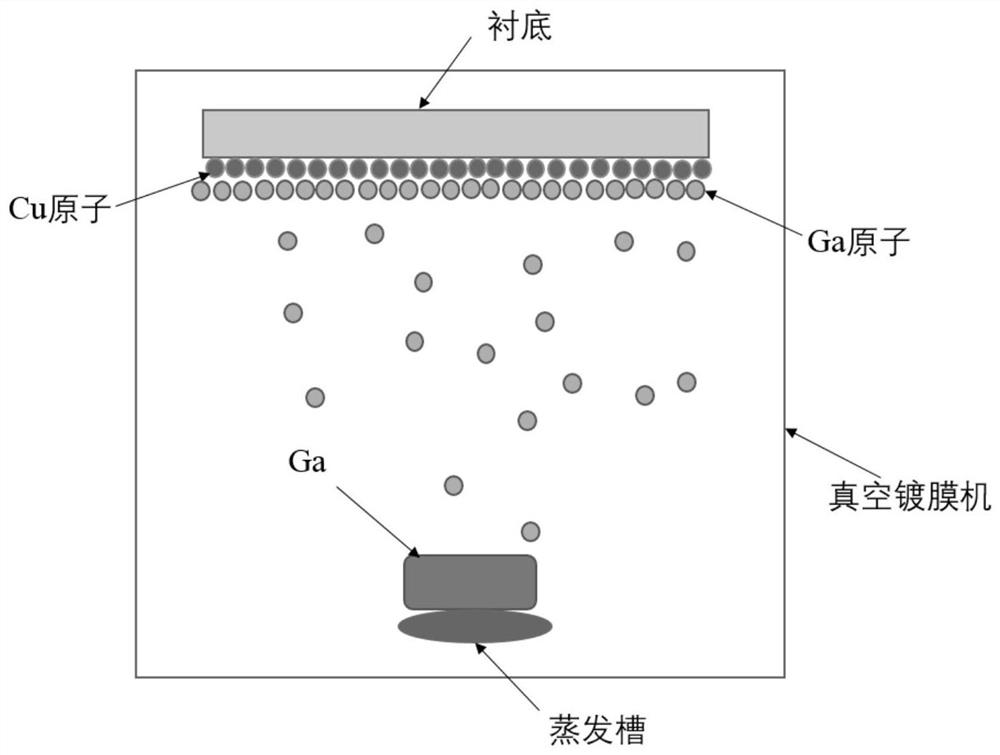

[0026] (2) The substrate obtained in step (1) is cleaned by deionized water, and put into the chamber of the vacuum coating machine, and copper (Cu) (purity: 99.9%-99.9999%) is put into the resistance of the vacuum coating machine in the evaporation tank.

[0027] (3) Close the chamber door of the vacuum coating machine, evacuate the chamber of the vacuum coating machine, and reduce the vacuum degree to 4×10 - 6 mbar.

[0028] (4) Regulate the current (A) of the thermal evaporation tank to uniformly deposit Cu atoms on the substrate, and obtain a Cu thin film on the su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com