Method for detecting pipeline defects by combining magnetic flux leakage and electromagnetic ultrasonic waves

A technology for detecting pipelines and magnetic flux leakage, which is applied to radio wave measurement systems, measuring devices, and magnetic variables of materials. operational effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

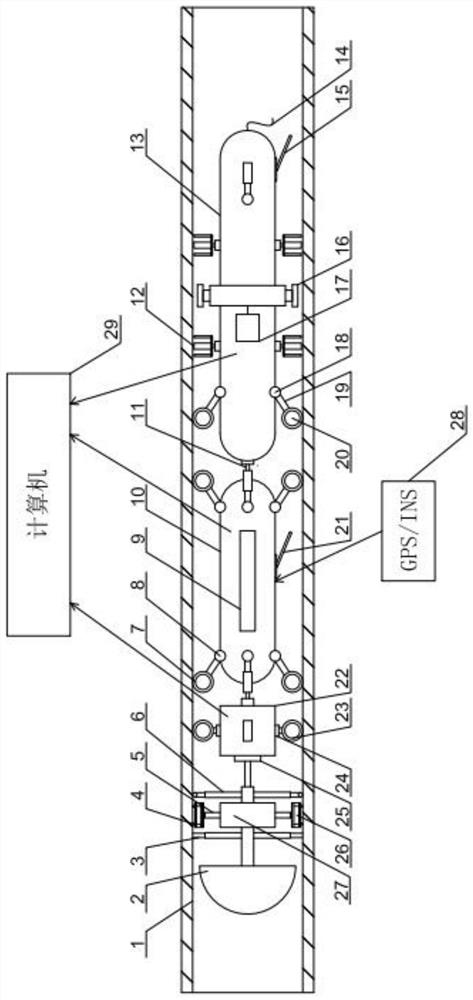

[0061] Embodiment 1: as figure 1 As shown, a device for combined magnetic flux leakage and electromagnetic ultrasonic detection of pipeline defects includes a GPS / INS integrated navigation system 28, a supporting wheeled pipeline robot, a three-axis magnetic flux leakage detection device, an electromagnetic ultrasonic detection device and a computer 29;

[0062] Satellite positioning and inertial navigation (GPS / INS) integrated navigation system 28 is used to accurately locate the specific position of the device in the pipeline, and at the same time obtain the specific position information of the detected defect;

[0063] Supporting the wheeled pipeline robot, which is used to make the three-axis magnetic flux leakage detection device and the electromagnetic ultrasonic detection device advance stably in the pipeline under test 1;

[0064] The three-axis magnetic flux leakage detection device is used to magnetize the tube wall to a near-saturation state by observing the deforma...

Embodiment 2

[0070] Embodiment 2: The structure of the device for detecting pipeline defects combined with magnetic flux leakage and electromagnetic ultrasonic in this embodiment is basically the same as that of the device for detecting pipeline defects in combination with magnetic flux leakage and electromagnetic ultrasonic in Embodiment 1, except that: Figure 3-6 As shown, the supporting wheeled pipeline robot is provided with a positioning antenna 21, and the positioning antenna 21 is wirelessly connected with a computer 29;

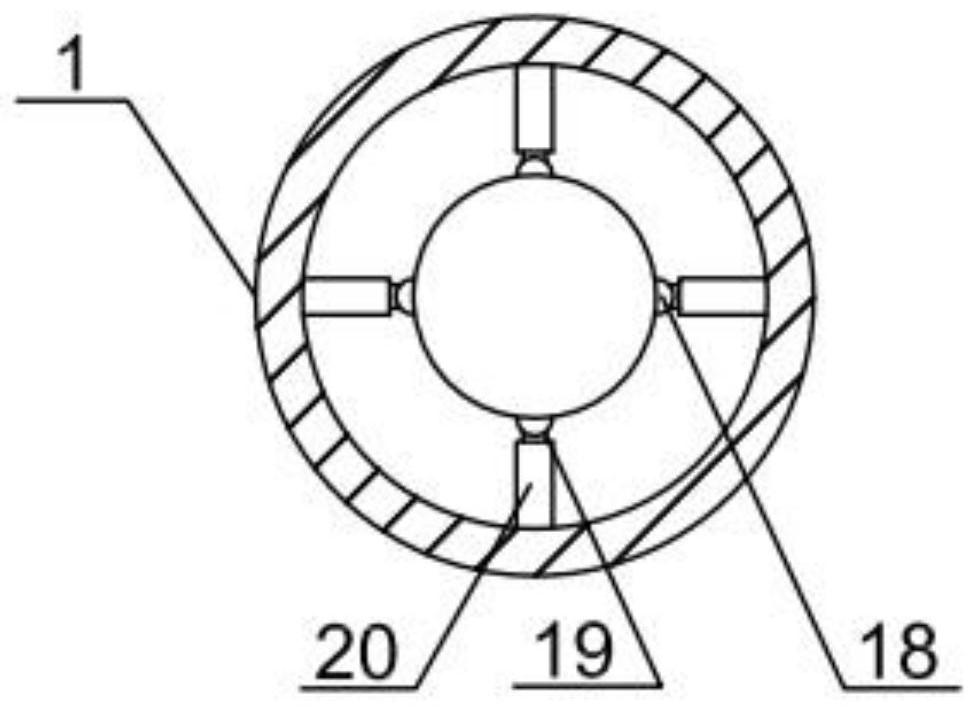

[0071] The three-axis magnetic flux leakage detection device includes an installation housing 13, and the installation housing 13 is provided with a brush set I12, a brush set II, and a magnetic flux leakage detection probe 16, and the brush set I12 and the brush set II are respectively located on the magnetic flux leakage detection Both sides of the probe 16, the brush set I12 and the brush set II are all attached to the inner wall of the pipeline 1, and the inst...

Embodiment 3

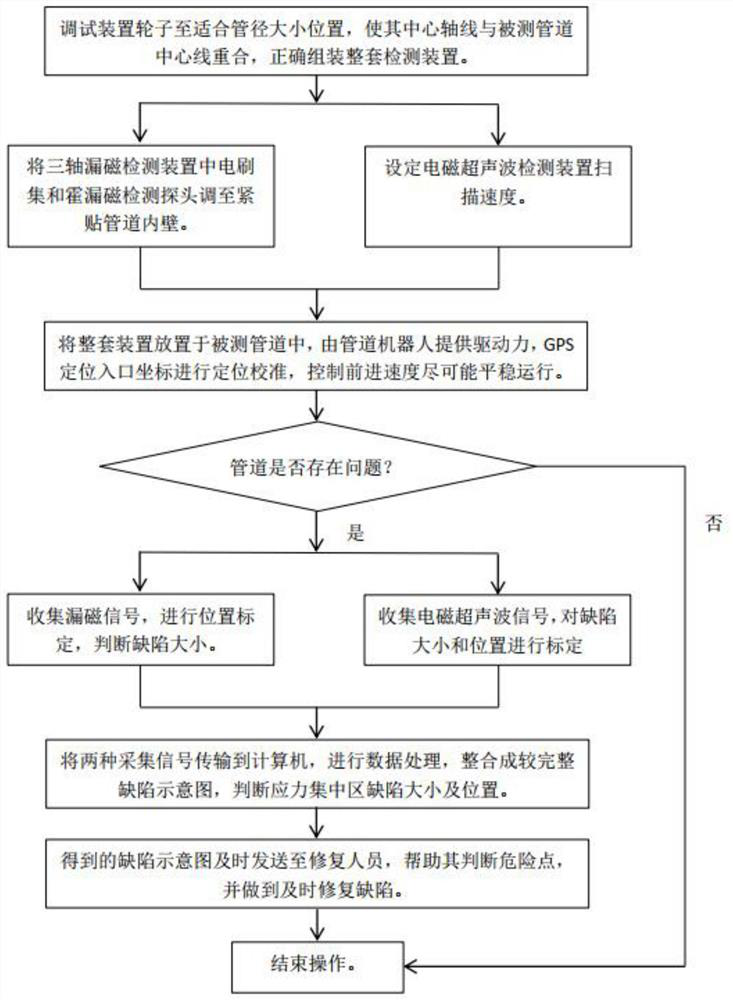

[0080] Embodiment 3: as figure 2 As shown, the identification and detection method of the device based on combined magnetic flux leakage and electromagnetic ultrasonic detection of pipeline defects includes the following specific steps:

[0081](1) Set the three-axis magnetic flux leakage detection device and the electromagnetic ultrasonic detection device at both ends of the supporting wheeled pipeline robot, and the GPS / INS integrated navigation system is set on the supporting wheeled pipeline robot; according to the diameter of the pipeline to be tested, adjust Support the wheeled pipeline robot, the three-axis magnetic flux leakage detection device and the electromagnetic ultrasonic detection device so that the central axis coincides with the central axis of the pipeline, and make the wheeled pipeline robot, the three-axis magnetic flux leakage detection device and the electromagnetic ultrasonic detection device coincide with the pipeline The inner wall fits;

[0082] (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com