Method for determining hydrolysis degree of partially hydrolyzed polyacrylamide for oil displacement

A technology of polyacrylamide and degree of hydrolysis, applied in chemical method analysis, chemical analysis by titration method, measuring device, etc., can solve the problems of large subjective judgment error, difficult to identify the color of titration end point, etc., and achieve the elimination of human error and control Product quality, the effect of improving economic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

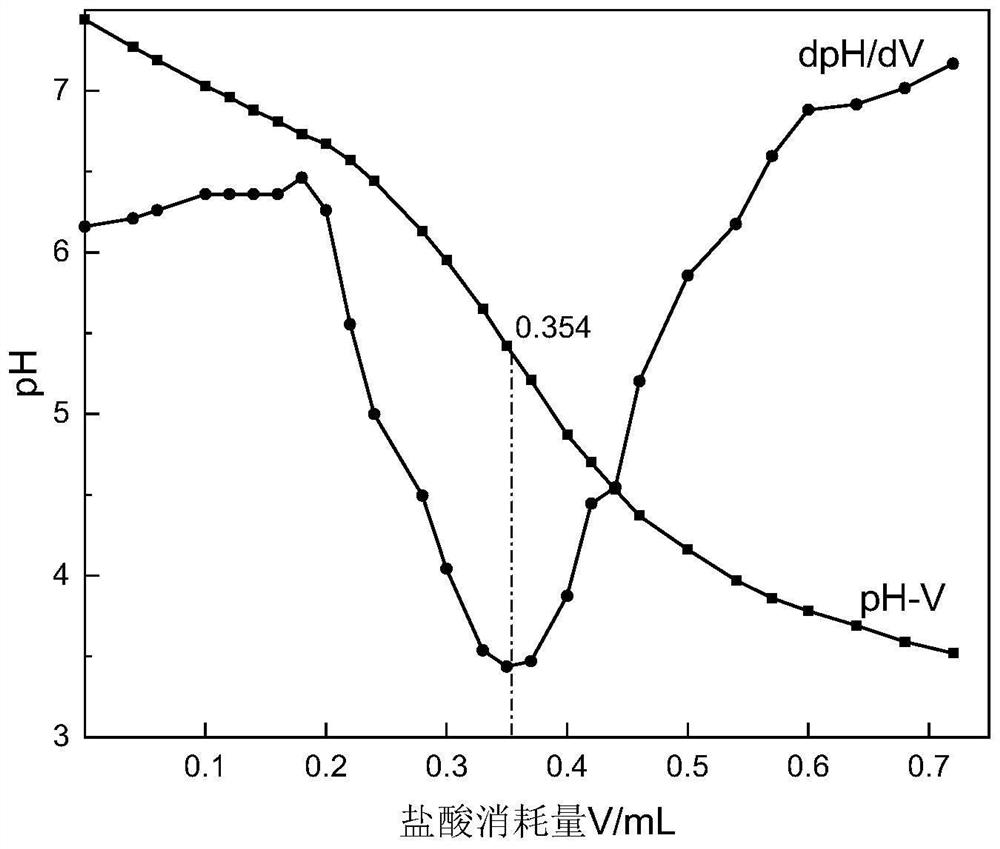

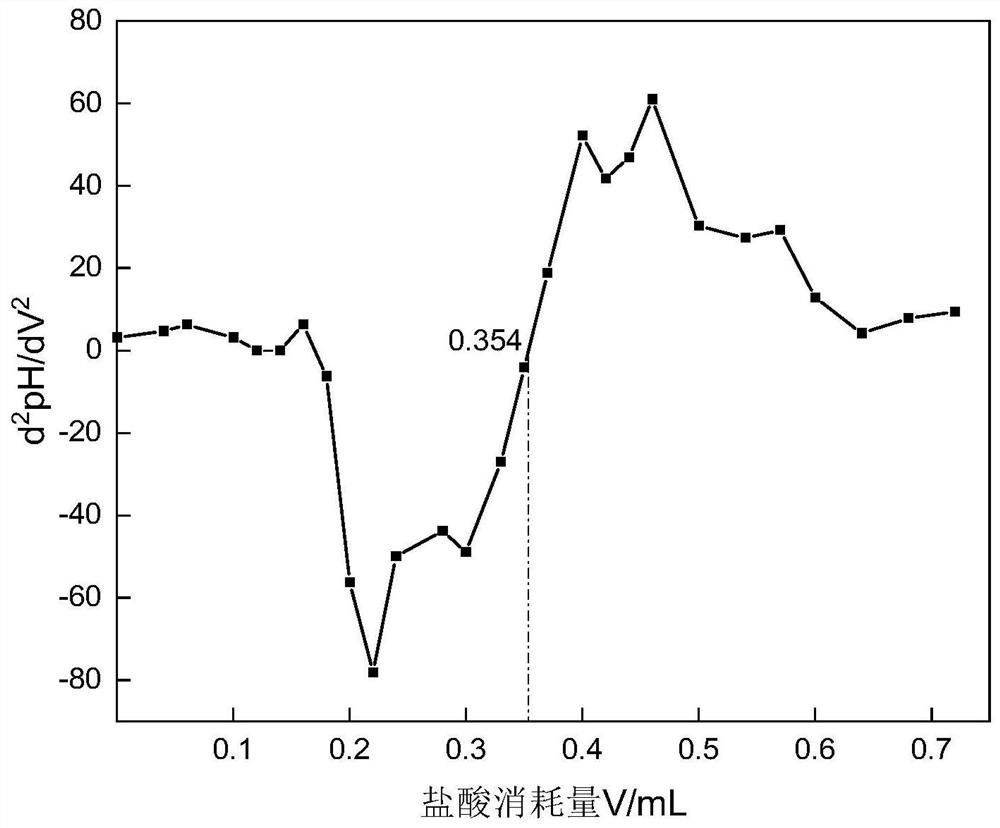

[0029] Example 1 Detection of the degree of hydrolysis of a certain medium and high-salt-resistant polymer A001 produced by France Eisen Company

[0030] The specific measurement steps are as follows:

[0031] 1. Determination of sample solid content

[0032] Determination method of polymer sample solid content S: according to SY / T 5862-2008.

[0033] 2. Preparation of sample solution

[0034] (1) Weigh (200-1 / S)g of distilled water (accurate to 0.01g) in a 500mL beaker;

[0035] (2) Accurately weigh (1 / S)g sample, accurate to 0.0001g, adjust the rotation speed of the vertical stirrer to (400±20)r / min, make the distilled water form a vortex, slowly and evenly dissolve the sample within 1min Withdraw the sample into the wall of the vortex, continue to stir for 2 hours, and prepare a solution with a concentration of 0.5%;

[0036] (3) Take 40.00 g of a 0.5% solution and 160.00 g of distilled water into a 500 mL beaker, stir with a magnetic stirrer for about 15 minutes until ...

Embodiment 2

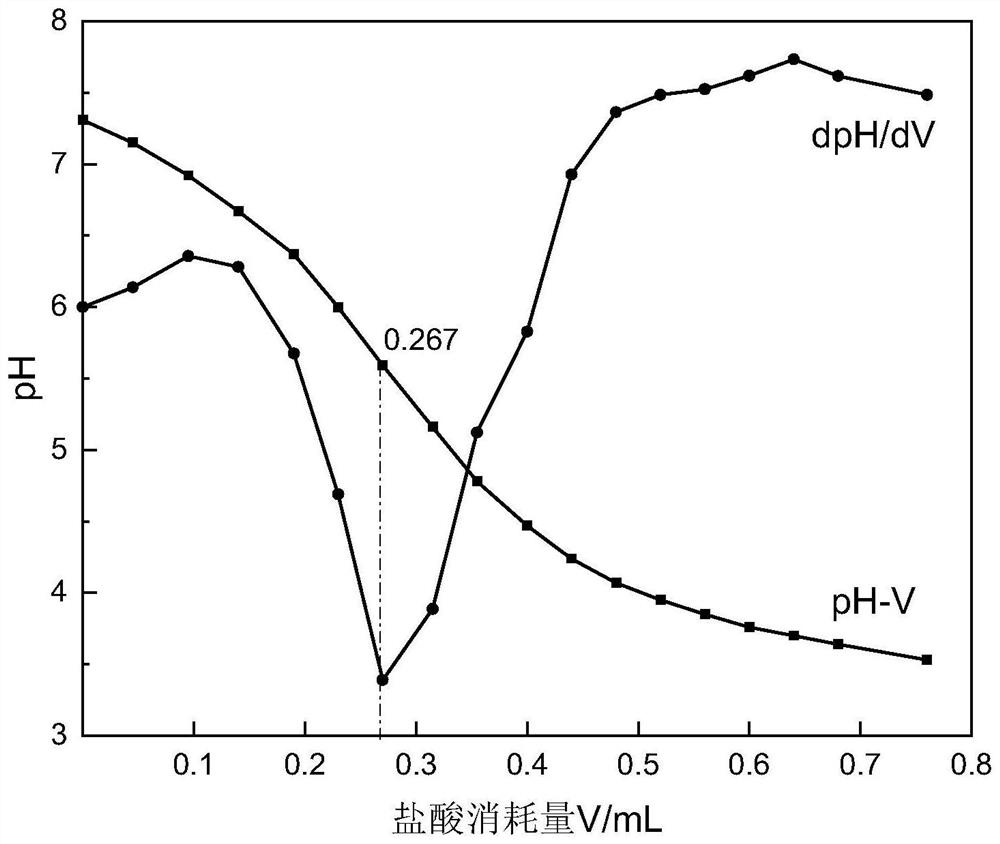

[0056] Example 2 Detection of the degree of hydrolysis of a certain high-resolution polymer A002 produced by Daqing Refining and Chemical Company

[0057] The specific measurement steps are as follows:

[0058] 1. Determination of sample solid content

[0059]Determination method of polymer sample solid content S: according to SY / T 5862-2008.

[0060] 2. Preparation of sample solution

[0061] (1) Weigh (200-1 / S)g of distilled water (accurate to 0.01g) in a 500mL beaker;

[0062] (2) Accurately weigh (1 / S)g sample, accurate to 0.0001g, adjust the rotation speed of the vertical stirrer to (400±20)r / min, make the distilled water form a vortex, slowly and evenly dissolve the sample within 1min Withdraw the sample into the wall of the vortex, continue to stir for 2 hours, and prepare a solution with a concentration of 0.5%;

[0063] (3) Take 40.00 g of a 0.5% solution and 160.00 g of distilled water into a 500 mL beaker, stir with a magnetic stirrer for about 15 minutes until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com