Instant purple coarse rice flour rich in anthocyanin and preparation method thereof

A technology of brown rice flour and anthocyanins, applied in the direction of food science, etc., can solve the problems of low degree of comprehensive utilization of purple rice, inability to impart viscosity to products, and long dissolution duration, so as to improve taste and digestibility, and shorten consumption Time, the effect of improving water solubility and gelatinization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

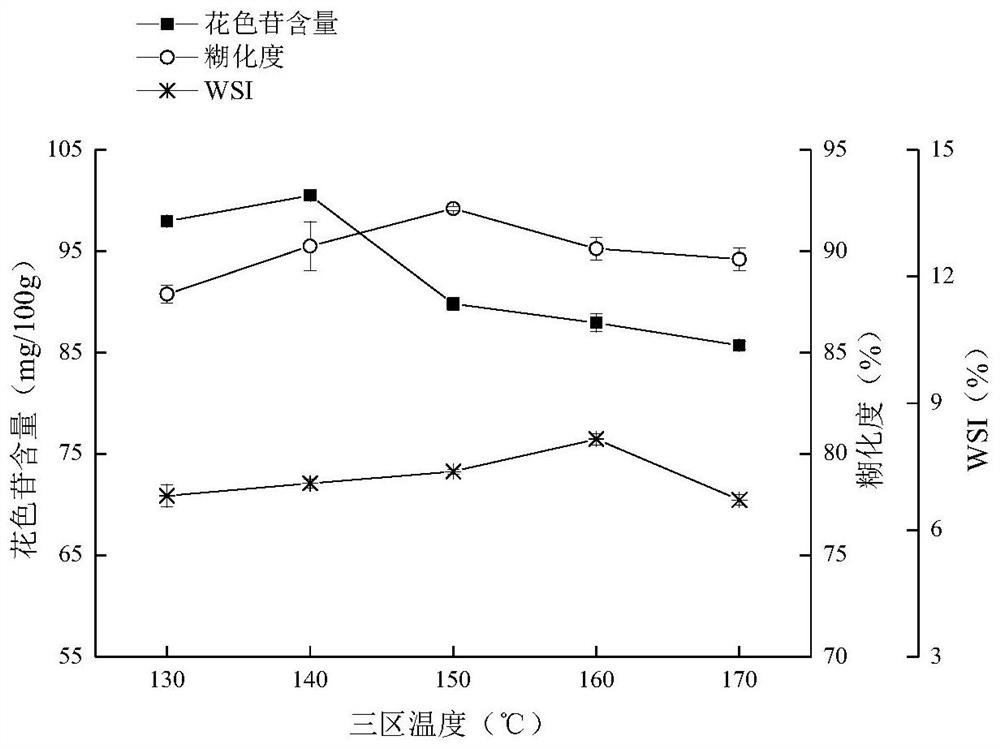

[0036] Embodiment 1 A kind of preparation method of instant purple brown rice flour rich in anthocyanins

[0037] (1) pulverizing: the purple brown rice raw material is pulverized with a pulverizer, and crosses a 60-mesh sieve to obtain the purple brown rice flour;

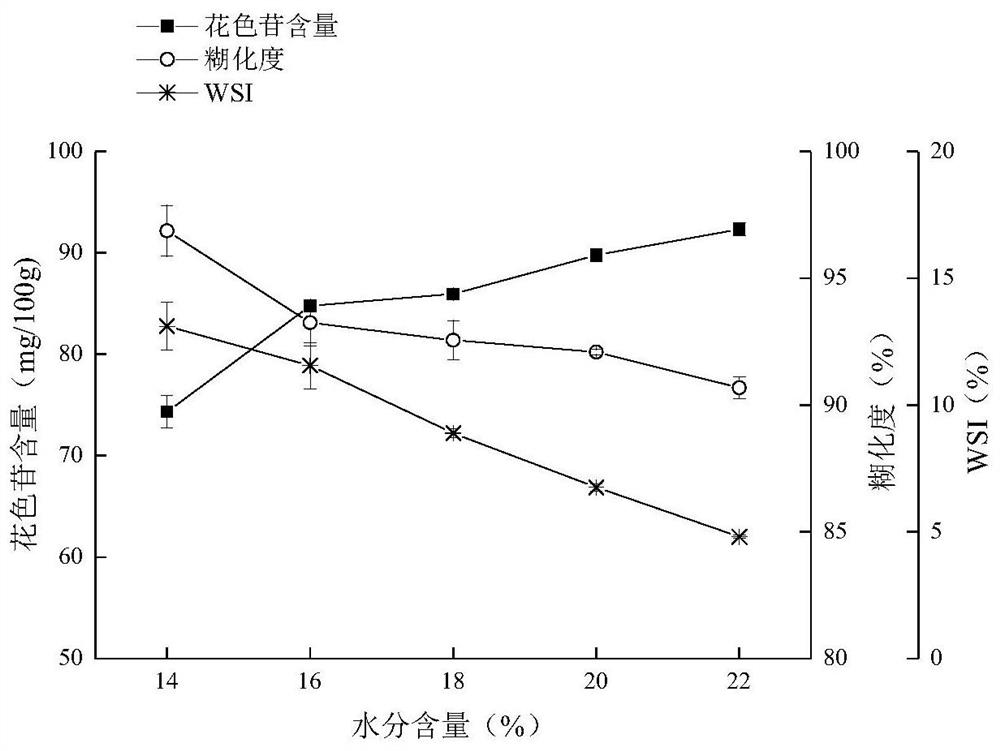

[0038] (2) Water adjustment: add appropriate amount of water to adjust the moisture content of the material to about 20%, and it is evenly wet;

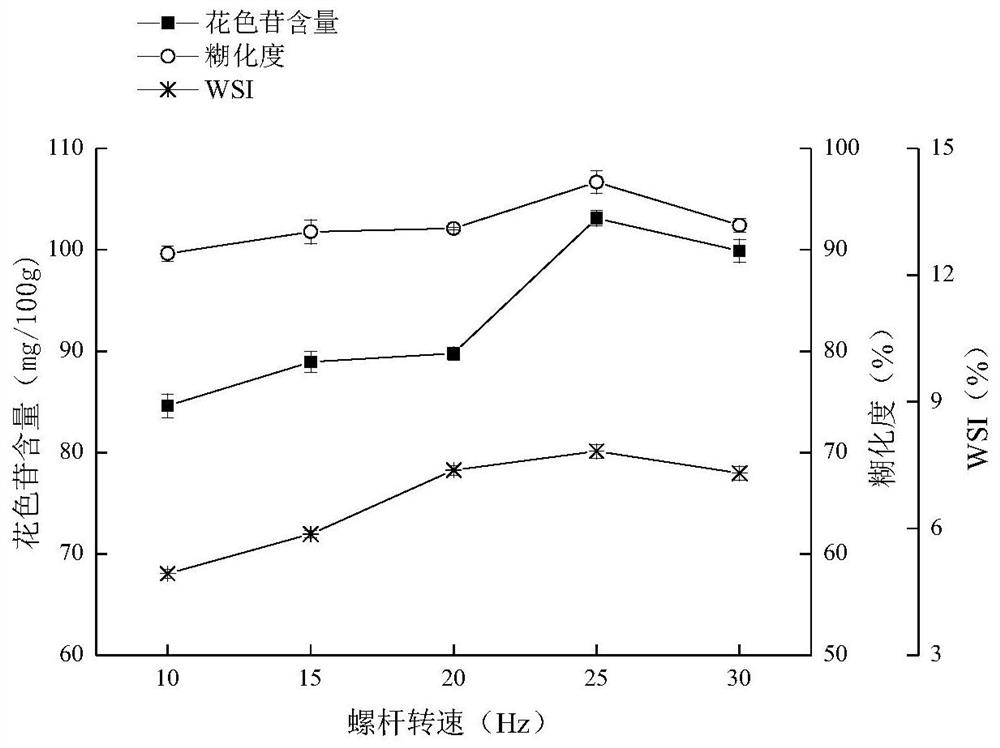

[0039] (3) Extrusion and puffing: Get the purple brown rice flour processed in step (2) and place it in the feed container of the extrusion extruder, set the temperature in the first zone to be 80°C, the temperature in the second zone to be 100°C, and the temperature in the third zone to be 140°C, screw speed 25Hz, feed rate 20Hz;

[0040] (4) Drying and crushing: Get the puffed product obtained in step (3) and dry it with hot air at 55° C. for 3 hours, and crush and sieve to obtain extruded puffed purple brown rice flour. The water solubility index is 6.04, the gelatin...

Embodiment 2

[0041] Embodiment 2 A kind of preparation method of instant purple brown rice flour rich in anthocyanins

[0042] (1) pulverizing: the purple brown rice raw material is pulverized with a pulverizer, and crosses a 60-mesh sieve to obtain the purple brown rice flour;

[0043] (2) Water adjustment: add appropriate amount of water to adjust the moisture content of the material to about 18%, and it is evenly wet;

[0044] (3) Extrusion and puffing: take the purple brown rice flour processed in step (2) and place it in the feed container of the extrusion extruder, set the temperature in the first zone to 90°C, the temperature in the second zone to 110°C, and the temperature in the third zone to 160°C, screw speed 20Hz, feed rate 15Hz;

[0045] (4) Drying and crushing: Get the puffed product obtained in step (3) and dry it with hot air at 55° C. for 3 hours, and crush and sieve to obtain extruded puffed purple brown rice flour. The water solubility index is 10.64, the gelatinization...

Embodiment 3

[0046] Embodiment 3 A kind of preparation method of instant purple brown rice flour rich in anthocyanins

[0047] (1) pulverizing: the purple brown rice raw material is pulverized with a pulverizer, and crosses a 60-mesh sieve to obtain the purple brown rice flour;

[0048] (2) Water adjustment: add appropriate amount of water to adjust the moisture content of the material to about 20%, and it is evenly wet;

[0049] (3) Extrusion and puffing: get the brown rice flour processed in step (2) and place it in the feeding container of the extrusion extruder, set the temperature in the first zone to be 85°C, the temperature in the second zone to be 105°C, and the temperature in the third zone to be 150°C, screw speed 25Hz, feed rate 10Hz;

[0050] (4) Drying and crushing: Get the puffed product obtained in step (3) and dry it with hot air at 55° C. for 3 hours, and crush and sieve to obtain extruded puffed purple brown rice flour. The water solubility index is 7.56, the gelatinizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com