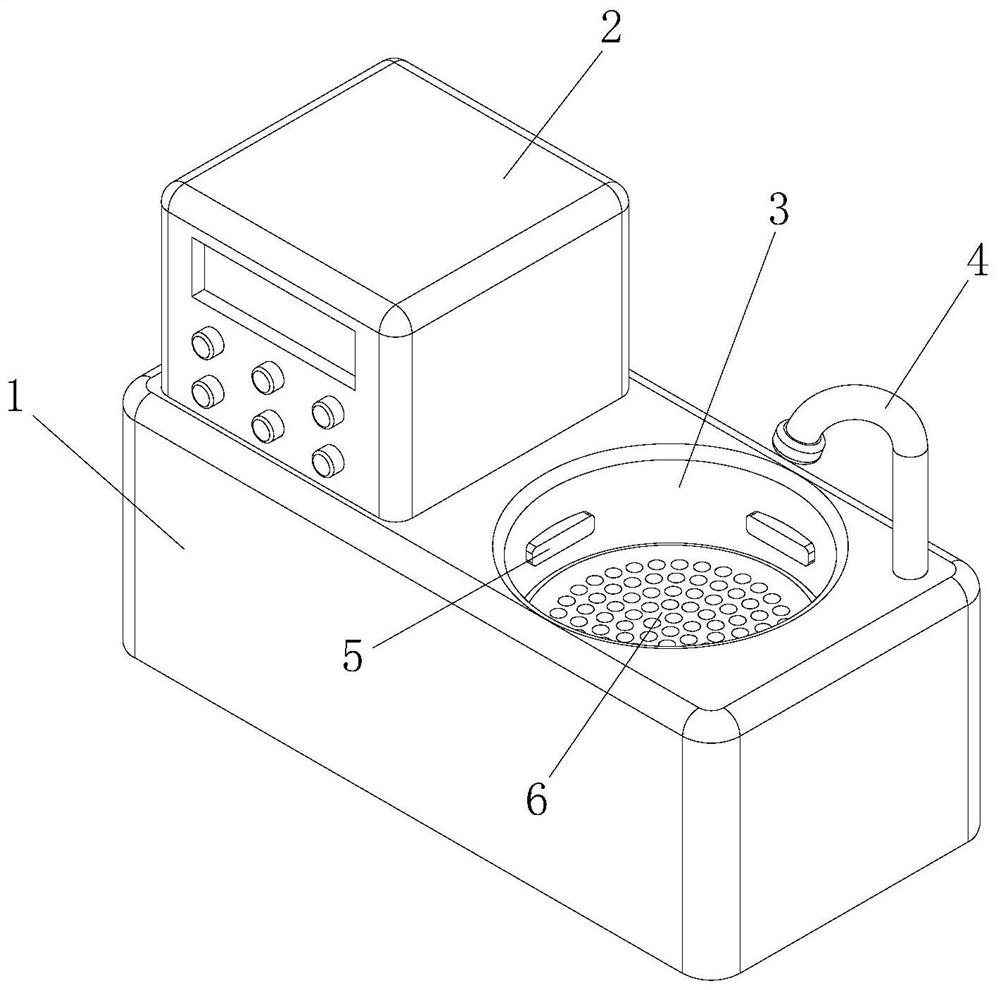

A technology and production equipment for making artificial teeth using peek resin composite material

A resin composite material and production equipment technology, applied in the field of artificial teeth, can solve the problems of uneven cleaning effect and residual gaps between workpieces, etc., achieve thorough cleaning, increase vibration frequency, and increase vibration frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

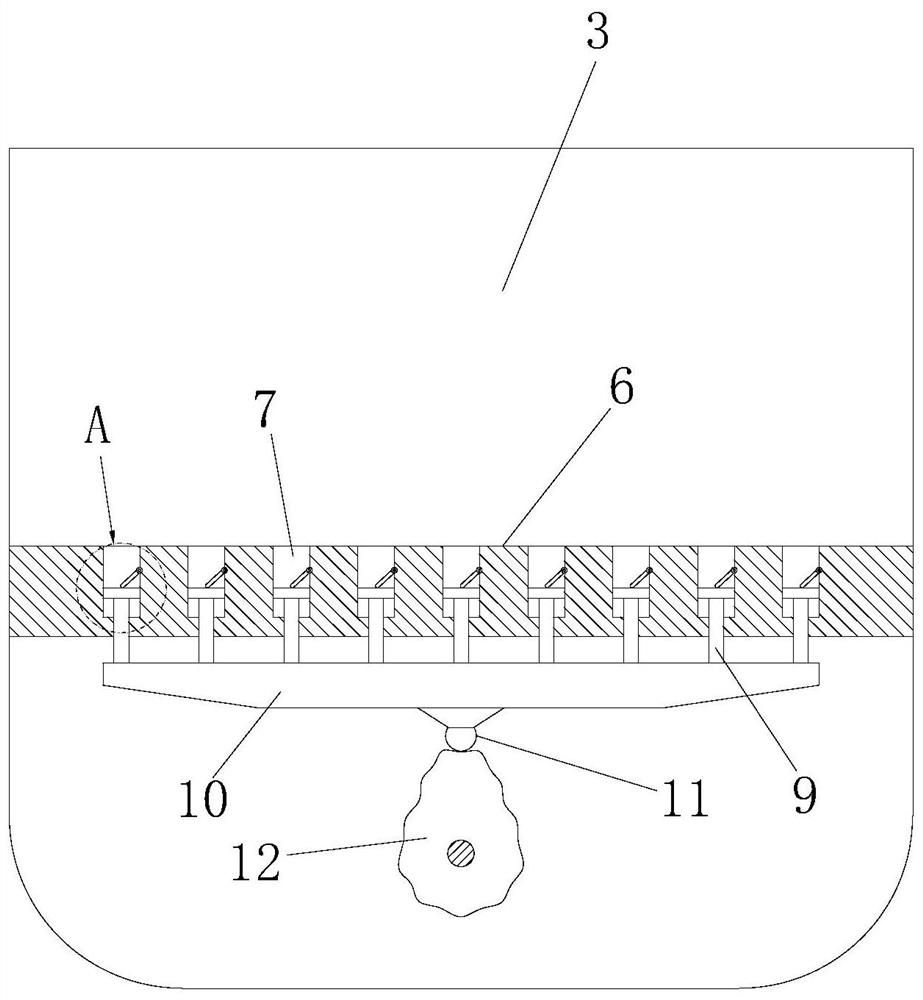

Method used

Image

Examples

Embodiment approach

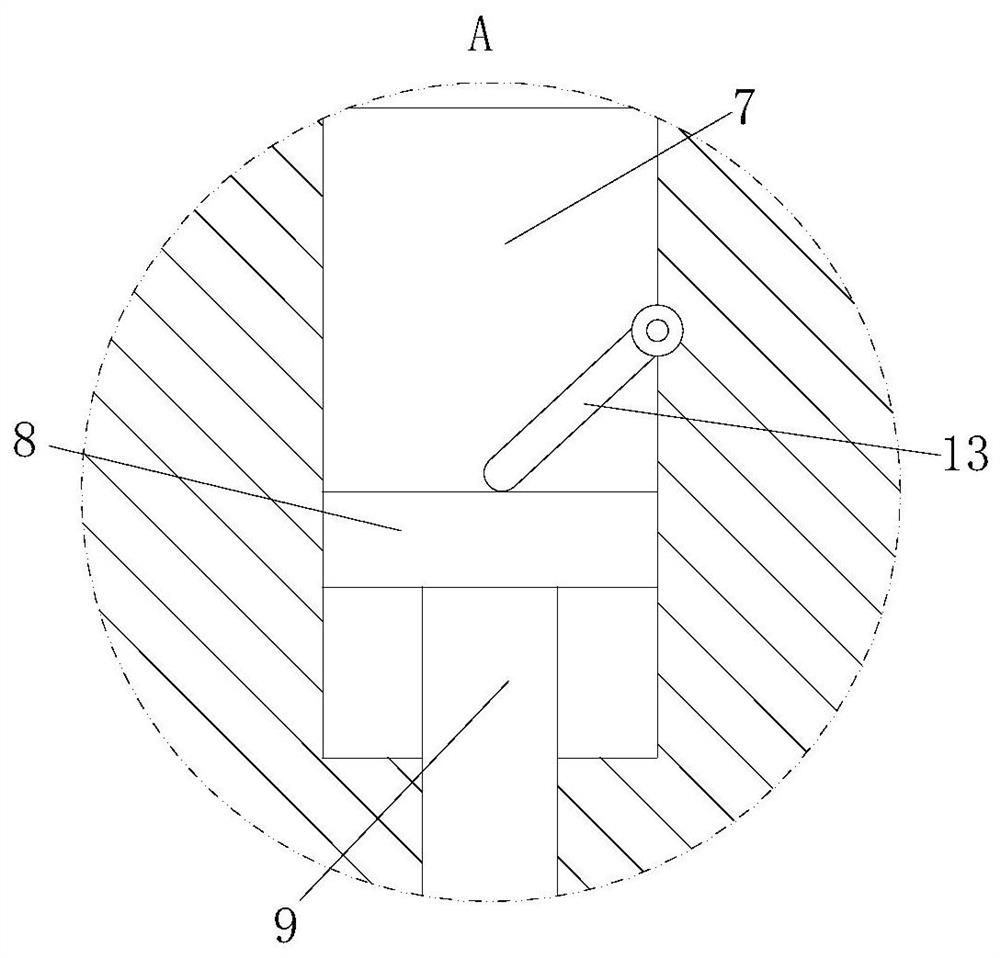

[0040] As an embodiment of the present invention, the movable rod 13 includes a base block 131 and two movable joints 132, and the movable joints 132 are hollow structures; Rod 133; the end of the connecting rod 133 away from the base block 131 extends into the movable section 132 and is slidably connected with it; the end of the connecting rod 133 located in the movable section 132 is fixedly connected to the limit block 134; the limit block No. 1 spring 135 is fixedly connected between 134 and the movable joint 132; during work, the movable rod 13 is pushed to rotate when the piston 8 moves up, and at the same time, under the extrusion of the piston 8, the connecting rod 133 stretches into the movable joint 132, and then the movable rod 13 is shortened, friction is generated between the movable joint 132 and the artificial tooth, and the artificial tooth is further pushed to turn over. In the process of the piston 8 continuously vibrating up and down, the artificial tooth is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com