Preparation method of halloysite-biochar composite material

A composite material and biochar technology, applied in chemical instruments and methods, water pollutants, other chemical processes, etc., can solve the problems of mechanical strength, difficult large-scale application, and long activation time of modified composite materials, and achieve The effect of promoting wide application, strong adsorption performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

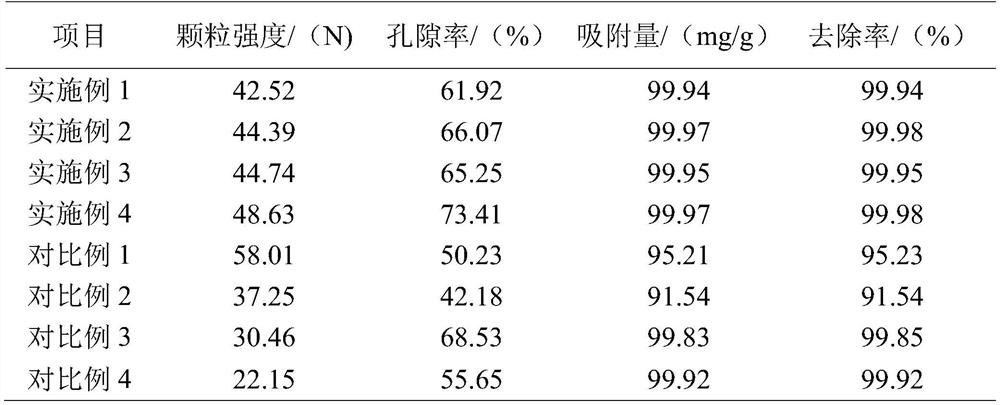

Embodiment 1

[0022] Preparation of halloysite-biochar composite material comprises the following steps:

[0023] (1) Coconut shells were pyrolyzed at 500°C for 50 minutes under nitrogen protection, and then ground through an 80-mesh sieve to obtain coconut shell biochar;

[0024] (2) Mix the pyrolyzed coconut shell biochar and halloysite powder according to the mass ratio of 1:0.8, and add water according to the ratio of solid to liquid at 1:10g / ml, and then vigorously After magnetic stirring for 1.5 hours, ultrasonic dispersion at 25kHz at 80°C for 3 minutes, then place the mixture at 30Mpa and heat at 120°C for 20 minutes to obtain the halloysite-biochar mixture;

[0025] (3) The halloysite-biochar mixture was centrifuged at 6000rpm for 8min, the supernatant was discarded, and dried at 100°C for 10h, and passed through an 80-mesh sieve to obtain a halloysite-halloysite composite material.

Embodiment 2

[0027] Preparation of halloysite-biochar composite material comprises the following steps:

[0028] (1) Coconut shells were pyrolyzed at 600°C for 55 minutes under nitrogen protection, and then ground through a 100-mesh sieve to obtain coconut shell biochar;

[0029] (2) Take the halloysite that is crushed through a 60-mesh sieve, and calcined at 850°C for 30 minutes to obtain calcined halloysite powder; and perform ultrasonic pre-dispersion under the conditions of ultrasonic power of 850W and ultrasonic frequency of 55kHz;

[0030] (3) Mix pyrolyzed coconut shell biochar and calcined halloysite powder according to the mass ratio of 1:0.9, and add water according to the material-to-liquid ratio of 1:20g / ml, and start at 55°C at 1800rpm After vigorous magnetic stirring for 2 hours, ultrasonic dispersion at 35kHz at 90°C for 5 minutes, then place the mixture at 50Mpa and heat at 150°C for 30 minutes to obtain a halloysite-biochar mixture;

[0031] (4) The halloysite-biochar mix...

Embodiment 3

[0033] Preparation of halloysite-biochar composite material comprises the following steps:

[0034] (1) Coconut shells were pyrolyzed at 700°C for 60 minutes under nitrogen protection, and then ground through a 100-mesh sieve to obtain coconut shell biochar;

[0035] (2) Take the halloysite that is crushed through an 80-mesh sieve, and calcined at 900°C for 35 minutes to obtain calcined halloysite powder; and perform ultrasonic pre-dispersion under the conditions of ultrasonic power of 900W and ultrasonic frequency of 65kHz;

[0036] (3) Mix pyrolyzed coconut shell biochar and calcined halloysite powder according to the mass ratio of 1:1, and add water according to the material-to-liquid ratio of 1:15g / ml. After vigorous magnetic stirring for 2 hours, ultrasonic dispersion at 35kHz and 90°C for 5 minutes, then place the mixture at 40Mpa and heat at 150°C for 30 minutes to obtain a halloysite-biochar mixture;

[0037] (4) The halloysite-biochar mixture was centrifuged at 7000r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com