Oversized high-alumina ceramic ball and preparation method thereof

A super-sized, high-alumina ceramic technology, applied in the field of super-sized high-alumina ceramic balls and its preparation, can solve the problems of product cracking, foaming, raw burning, etc., achieve a dense matrix without holes, simple preparation process, and low equipment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

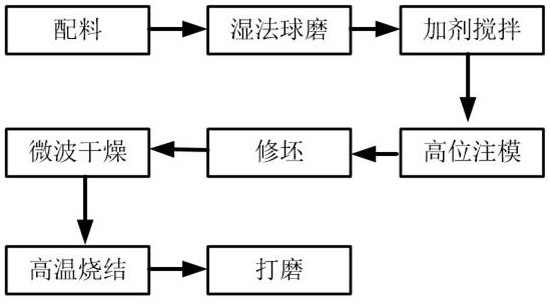

Method used

Image

Examples

Embodiment 1

[0018] According to the mass percentage, weigh 90% of Al 2 o 3 Powder, 5% CaCO 3 powder, 3% SrO 2 powder, 2% kaolin, of which Al 2 o 3 The powder purity is 95.0%, the particle size is 60nm, CaCO 3 The purity of the powder is 99.9%, the particle size is 50nm, SrO 2 The purity of powder is 99.9%, the particle size is 50nm, the purity of kaolin is 99.9%, the particle diameter is 50nm.

[0019] Will Al 2 o 3 Powder, CaCO 3 Powder, SrO 2 Powder and kaolin are put into a ball mill tank with polyurethane lining, and 10mm ceramic balls are loaded according to the ball-to-material ratio of 1.5, and Al 2 o 3 Powder, CaCO 3 Powder, SrO 2 0.8% of the total mass of powder and kaolin in deionized water, the filling rate of the ball mill tank is 75%, the control ball mill speed is 30 rpm, and the ball mill is carried out for 45 hours; the slurry after ball milling is transferred to the stirring container, and added to the ball mill Suspending agent with 1% slurry mass, stirred ...

Embodiment 2

[0021] According to the mass percentage, weigh 93.5% Al 2 o 3 Powder, 3.5% CaCO 3 powder, 2% SrO 2 powder, 1% kaolin, of which Al 2 o 3 The powder purity is 95.0%, the particle size is 100nm, CaCO 3 The purity of the powder is 99.9%, the particle size is 200nm, SrO 2 The purity of powder is 99.9%, the particle size is 200nm, the purity of kaolin is 99.9%, the particle diameter is 200nm.

[0022] Will Al 2 o 3 Powder, CaCO 3 Powder, SrO 2 Powder and kaolin are put into a ball mill tank with polyurethane lining, and 12mm ceramic balls are loaded according to the ball-to-material ratio of 1.5, and Al 2 o 3 Powder, CaCO 3 Powder, SrO 2 Powder, kaolin total mass of 0.8% deionized water, the filling rate of the ball milling tank is 75%, the ball milling speed is controlled to be 32 rpm, and the ball milling is carried out for 48 hours; the slurry after ball milling is transferred to the stirring container, and added to the ball milling Suspending agent with 2% slurry m...

Embodiment 3

[0024] According to the mass percentage, weigh 95.5% Al 2 o 3 Powder, 2.5% CaCO 3 powder, 1.2% SrO 2 powder, 0.8% kaolin, of which Al 2 o 3 Powder purity is 95.0%, particle size is 200nm, CaCO 3 The purity of the powder is 99.9%, the particle size is 400nm, SrO 2 The purity of powder is 99.9%, the particle size is 400nm, the purity of kaolin is 99.9%, the particle diameter is 500nm.

[0025] Will Al 2 o 3 Powder, CaCO 3 Powder, SrO 2Powder and kaolin are put into a ball mill tank with polyurethane lining, and 15mm ceramic balls are loaded according to the ball-to-material ratio of 1.5, and Al 2 o 3 Powder, CaCO 3 Powder, SrO 2 0.8% deionized water of powder and kaolin total mass, the filling rate of the ball milling tank is 75%, the ball milling speed is controlled to be 35 rpm, and the ball milling is carried out for 55 hours; the slurry after ball milling is transferred to the stirring container, and added to the ball mill Suspending agent with 2% slurry mass, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com