Talcum powder filled biological full-degradable film blowing material and preparation method thereof

A talcum powder and fully degradable technology, which is applied in the field of preparation of fully biodegradable blown film materials, can solve the problems of poor comprehensive physical and chemical properties, inability to achieve the use effect of plastic films, high raw material costs, etc., to achieve improved compatibility, processing Good performance and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

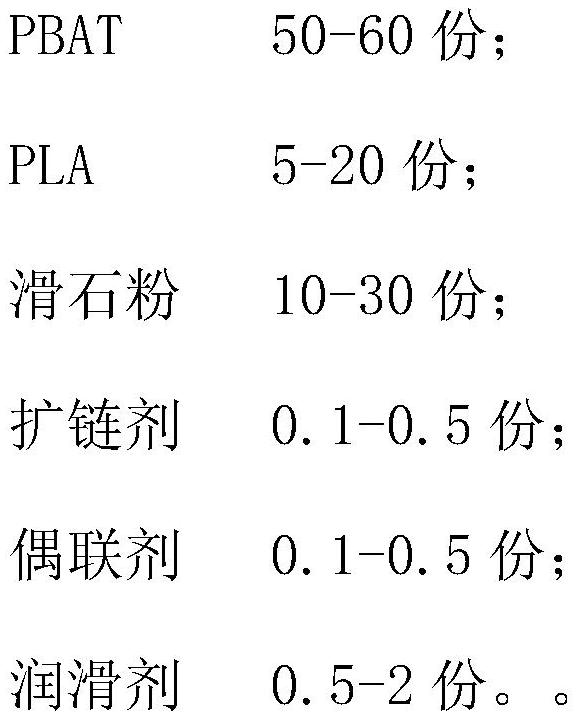

[0023] A biodegradable blown film material filled with talcum powder, each component is calculated by mass parts, including,

[0024]

[0025] The talcum powder mesh number is 1000 mesh.

[0026] The chain extender is styrene-acrylonitrile-glycidyl methacrylate.

[0027] The coupling agent is KH-560.

[0028] Lubricants are stearates.

[0029] The preparation method of the above-mentioned biodegradable blown film material filled with talcum powder comprises the following steps,

[0030] (1) PBAT, PLA, and chain extenders are added into the high-mixer according to the proportion, and after mixing evenly, the carrier particles are prepared by granulating through a twin-screw extruder;

[0031] (2) Add talcum powder, coupling agent and lubricant into the high-mixer, set the high-mixing temperature to 80°C, and the speed to 400r. After blending for 15 minutes, add the carrier particles in step 1, and continue mixing evenly. A biodegradable blown film material filled with ta...

Embodiment 2

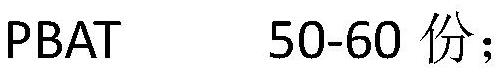

[0033] A biodegradable blown film material filled with talcum powder, each component is calculated by mass parts, including,

[0034]

[0035]

[0036] The talcum powder mesh number is 5000 mesh.

[0037] The chain extender is methyl methacrylate-glycidyl methacrylate.

[0038] The coupling agent is A-187.

[0039] The lubricant is EBS.

[0040] The preparation method of the above-mentioned biodegradable blown film material filled with talcum powder comprises the following steps,

[0041] (1) PBAT, PLA, and chain extenders are added into the high-mixer according to the proportion, and after mixing evenly, the carrier particles are prepared by granulating through a twin-screw extruder;

[0042] (2) Add talcum powder, coupling agent and lubricant to the high-mixer, set the high-mix temperature to 100°C, and the speed to 600r. After blending for 15 minutes, add the carrier particles in step 1 and continue to mix evenly. A biodegradable blown film material filled with ta...

Embodiment 3

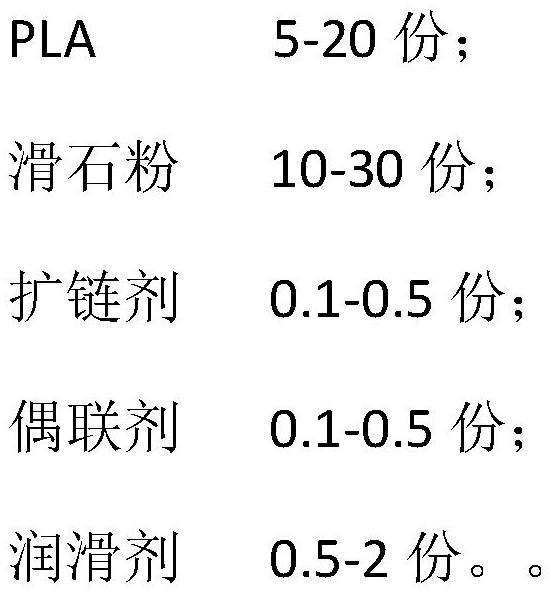

[0044] A biodegradable blown film material filled with talcum powder, each component is calculated by mass parts, including,

[0045]

[0046] The mesh number of talcum powder is 3000 mesh.

[0047] The chain extender is styrene-acrylonitrile-glycidyl methacrylate.

[0048] The coupling agent is Z-6040.

[0049] Lubricants are stearates.

[0050] The preparation method of the above-mentioned biodegradable blown film material filled with talcum powder comprises the following steps,

[0051] (1) PBAT, PLA, and chain extenders are added into the high-mixer according to the proportion, and after mixing evenly, the carrier particles are prepared by granulating through a twin-screw extruder;

[0052] (2) Add talcum powder, coupling agent and lubricant into the high-mixer, set the high-mixing temperature to 90°C, and the speed to 500r. After blending for 15 minutes, add the carrier particles in step 1, and continue mixing evenly. A biodegradable blown film material filled with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com