Coal gasification slag recycling system and method

A coal gasification slag and flue gas technology, applied in gasification process, manufacture of combustible gas, solid fuel, etc., can solve the problems of high cost and difficulty in waste slag treatment, and achieve low cost, reduce ecological environment pressure, and save resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

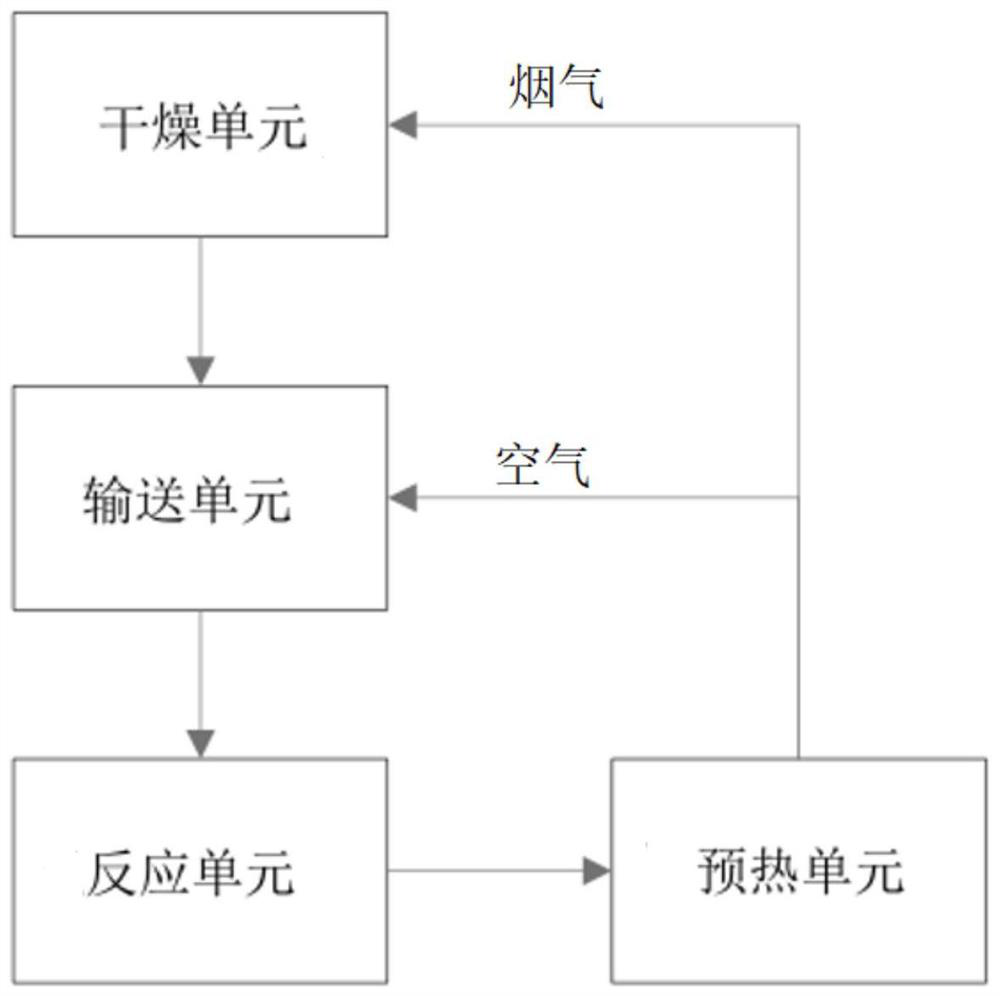

[0035] Such as figure 1As shown, a coal gasification slag recycling system includes a drying unit 1, a conveying unit 2, a reaction unit 3 and a preheating unit 4 connected in sequence; the drying unit 1 is used for drying and preheating the coal gasification slag; Unit 2 is used to transport and reheat the dried and preheated coal gasification slag; the reaction unit 3 is used to burn the reheated coal gasification slag; the preheating unit 4 is used to reheat the reaction unit 3 The flue gas produced is recycled. Specifically, the preheating unit 4 includes an air inlet, an air outlet and a flue gas outlet, the air outlet is connected to the conveying unit 2, the flue gas outlet is connected to the drying unit 1, and the heat exchange between the high temperature flue gas and the normal temperature air is carried out in the preheating unit 4 , the high-temperature flue gas is the flue gas generated in the reaction unit 3, and the normal-temperature air is the air coming in ...

Embodiment 2

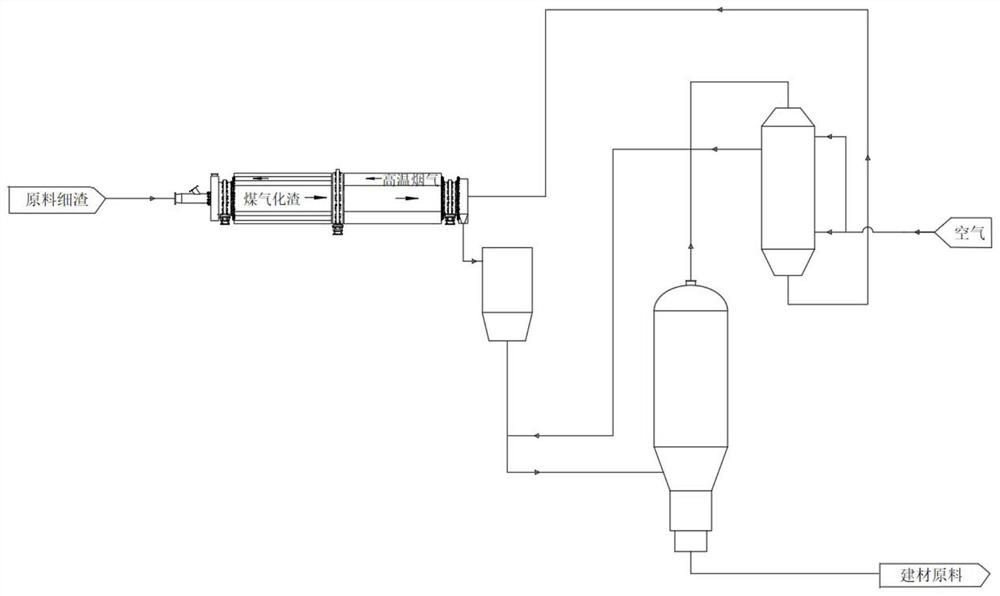

[0045] Such as figure 2 As shown, it is basically the same as in Example 1. Specifically, in this implementation, the drying unit 1 is a drying kiln, which includes a drying cylinder, one end of the drying cylinder is the inlet of coal gasification slag, the other end is the outlet of coal gasification slag and the The end is connected to the conveying unit 2, and the inside of the drying cylinder is provided with a heat exchange tube, which is connected to the flue gas outlet in the preheating unit 4, and the flow direction of the flue gas in the drying cylinder is opposite to the flow direction of the coal gasification slag . Specifically, with figure 2 As a benchmark, the left end of the drying cylinder is the inlet of coal gasification slag, the right end of the drying cylinder is the outlet of coal gasification slag, the flow direction of coal gasification slag is from left to right, and the flow direction of low-temperature flue gas in the drying cylinder is from Rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com