Electric control system of force actuator in large astronomic telescope

A technology of astronomical telescopes and force actuators, applied in telescopes, storage systems, instruments, etc., can solve the problems of deformation control and displacement control of sub-mirrors that have not yet been designed, and achieve the effect of increasing mirror deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

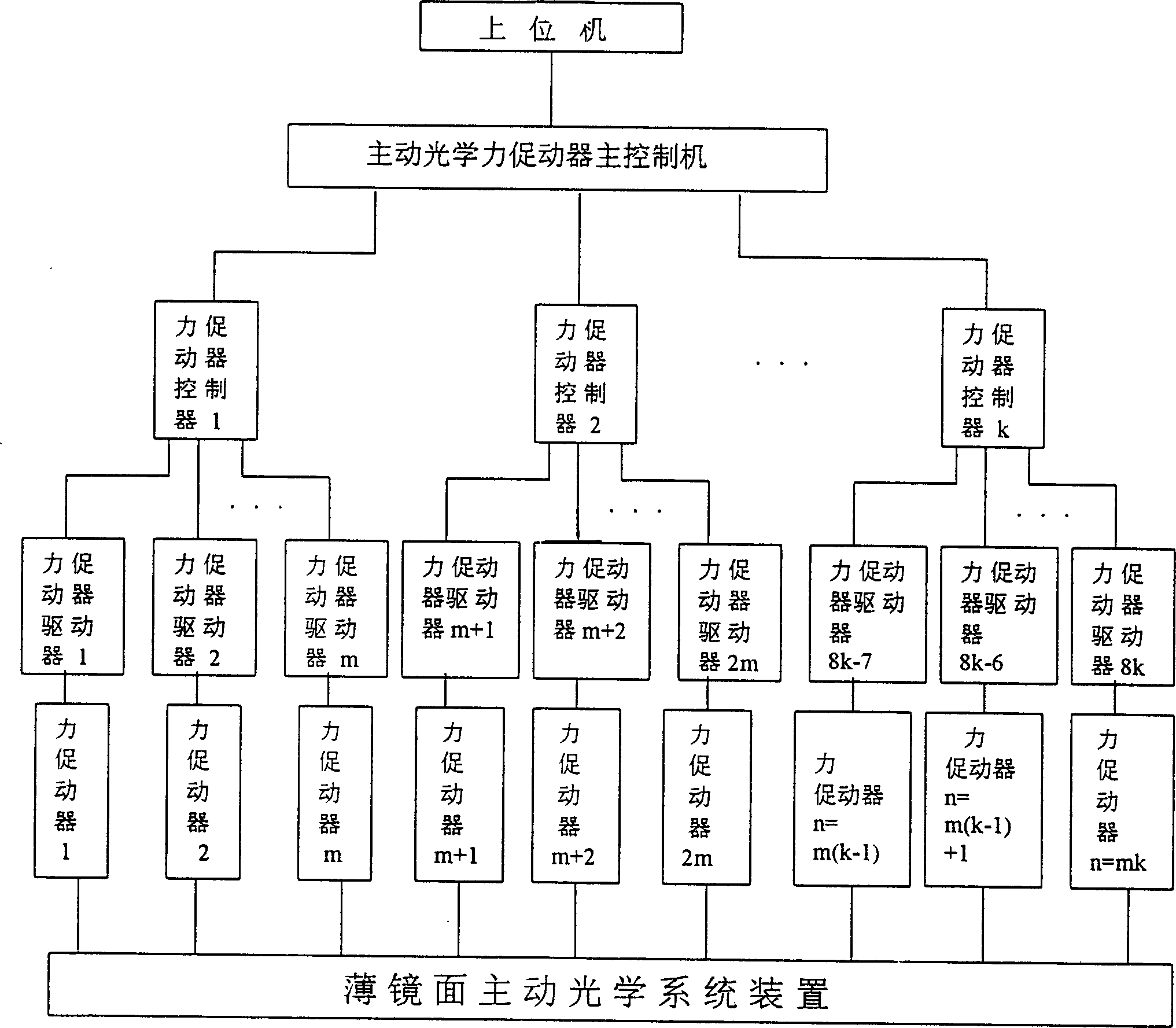

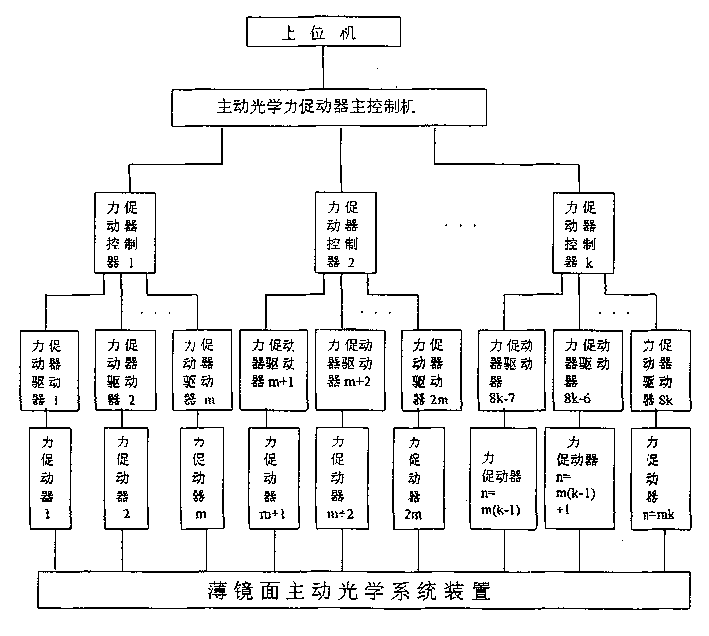

[0009] Embodiment 1, with reference to figure 1 , Figure 2: LAMOST astronomical telescope corrected by Schmidt

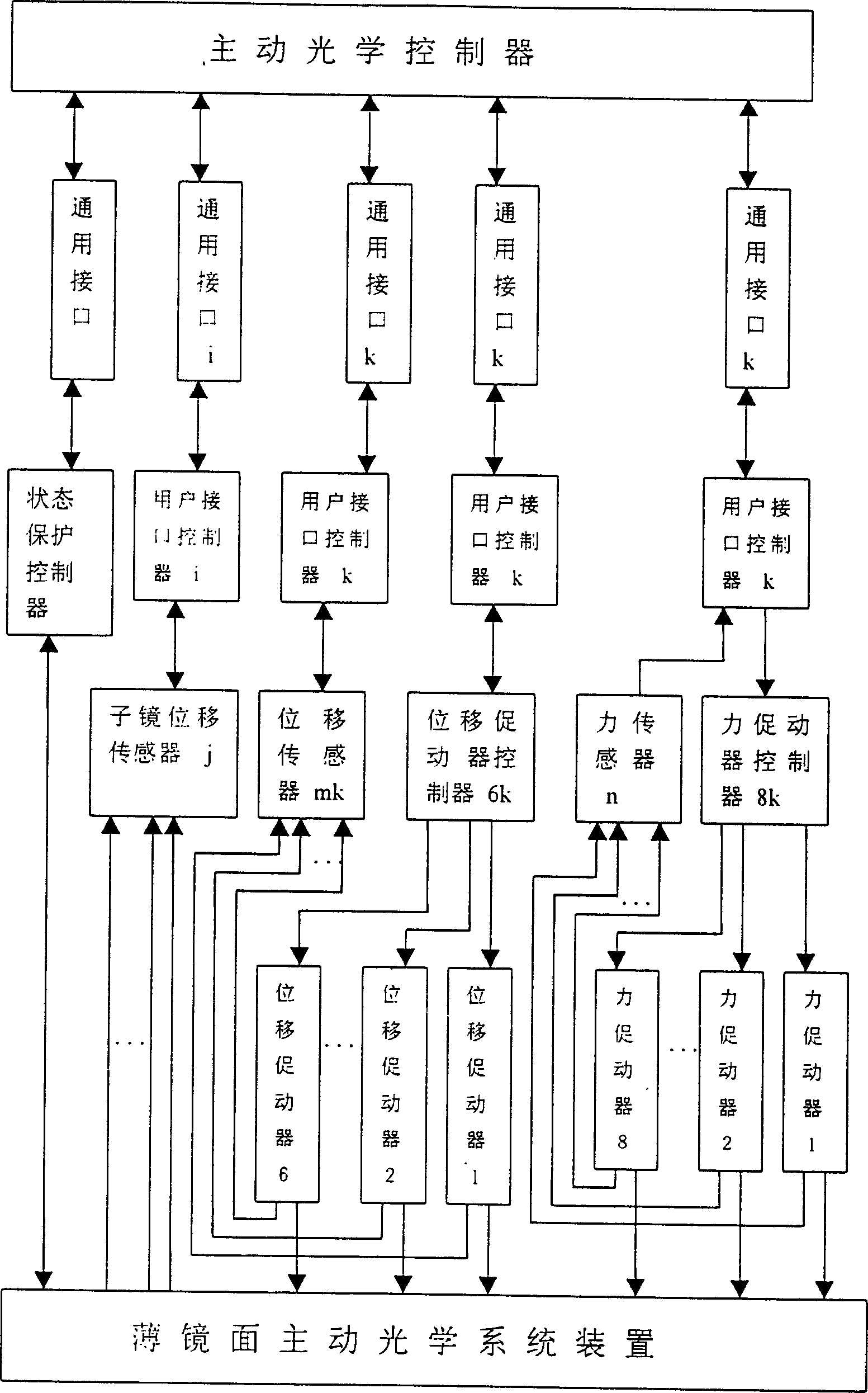

[0010] DETAILED DESCRIPTION Plate M A and the spherical primary mirror M B composition. m A It is made of 24 thin mirror hexagonal sub-mirrors with a thickness of 25mm; M B It is composed of 37 hexagonal sub-mirrors spliced separately. The system obtains control parameters through the local area network to change M in real time. A The aspheric surface shape of the sub-mirror. When the telescope is running, such that M A During the entire observation process, the computer performs real-time control to change the shape of the aspheric surface. A force actuator and a displacement actuator are placed on the back of the sub-mirror, and the control motor used by the force actuator is a Swiss stepping motor. Its main technical indicators are: number of phases 4, distribution mode 2-2, step angle 15°, winding resistance of each phase 120Ω, excitation mode is self...

Embodiment 2

[0011] Embodiment 2 is basically the same as Embodiment 1, but the interface board is replaced by PC104 bus box to reduce the installation size. A control box composed of a bus system including a CPU, including a processor, an electronic disk, a digital interface, an A / D interface, a D / A interface, a communication interface and an actuator controller. On the back of the sub-mirror with a very limited area, the construction space is greatly limited. Using the control box can reduce the volume of the controller and the number of wiring, and improve the feasibility of actual engineering construction. For larger telescopes, LAN transmission or wireless transmission between the control system and each controller can also be realized. The communication of this system adopts the method of safety control word and automatic identity authentication. The processor in the intelligent control box automatically analyzes the data and judges the correctness of the order, thereby improving the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com