An improved rectangular electrical connector and its production process

An electrical connector, rectangular technology, applied in the field of improved rectangular electrical connector and its production process, can solve the problems of instability, poor contact, increased use cost, etc., to achieve stable connection, improve dryness, and facilitate loading and unloading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

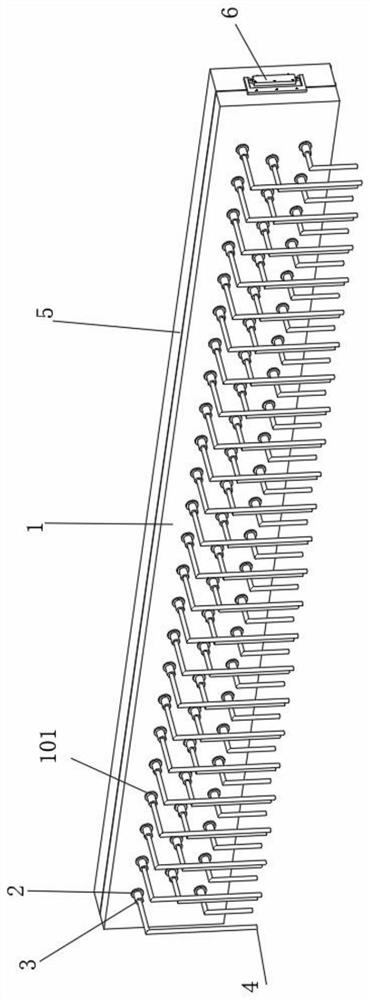

[0046] Such as figure 1 As shown, an improved rectangular electrical connector, the improved rectangular electrical connector includes a head shell and a seat shell, the head shell and the seat shell are all made of LCP composite material, and the LCP composite material consists of the following parts by weight The composition of the numbers: 30-50 parts of LCP plastic raw materials, 25-35 parts of polyamide, 12-14 parts of low-dielectric glass fiber, 5.5-67.2 parts of polymethylphenylsiloxane, 1.6-2.5 parts of silicone powder , 2.2-2.8 parts of titanate coupling agent, 1681.8-2.8 parts of phosphite antioxidant, 2-4 parts of antimony trioxide.

[0047] An improved production process of a rectangular electrical connector, the production process steps are as follows:

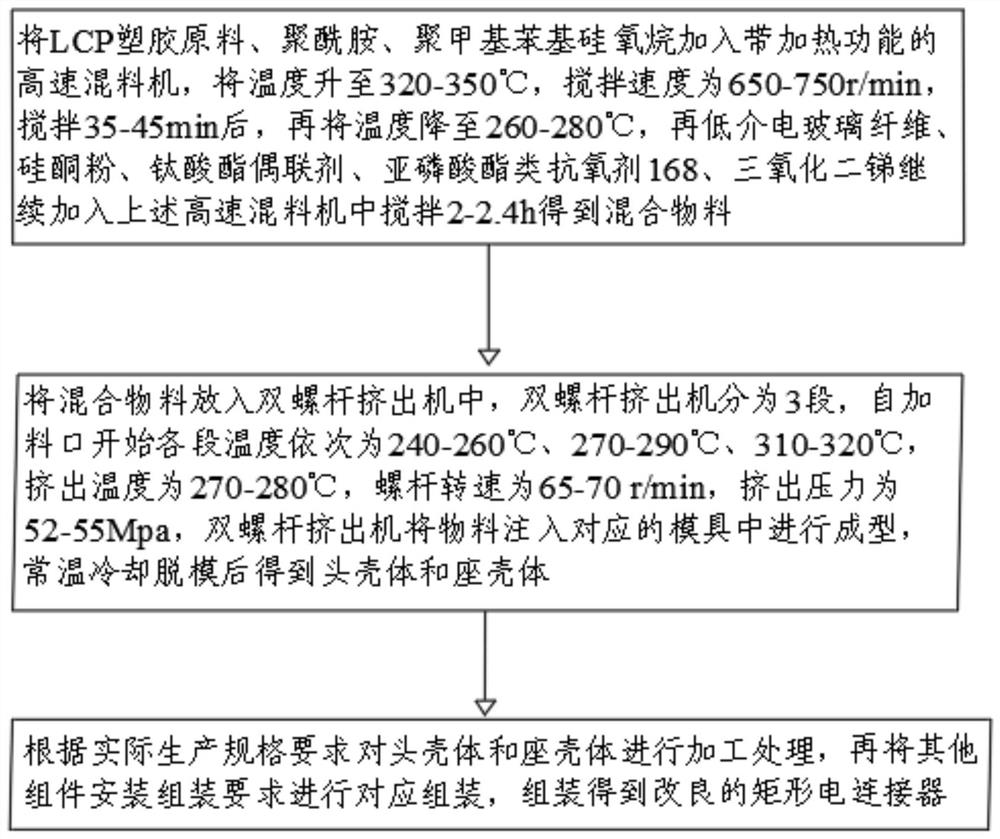

[0048] Step 1: Add LCP plastic raw materials, polyamide, and polymethylphenylsiloxane into a high-speed mixer with heating function, raise the temperature to 320-350°C, stir at 650-750r / min, and stir for 35- Aft...

Embodiment 2

[0053] Embodiment 2 is a further improvement to Embodiment 1.

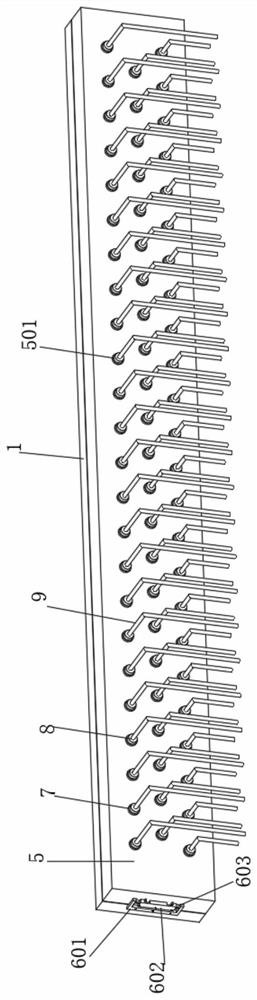

[0054] Such as figure 2 , 3 , 4, 5, 6, 7, 8, 9, and 11, the improved rectangular electrical connector obtained by the production process includes a head shell 1 and a seat shell 5, and the left side wall of the head shell 1 is evenly opened with The first installation hole 101 is opened in a dislocation adjacent to the first installation hole 101 in the vertical direction. The first installation sleeve 2 is fixedly installed in the first installation hole 101 of the head housing 1, and the outer wall of the pin 3 and the first The inner walls of the installation holes 101 are filled with AB glue, and the outer wall of the pin 3 and the inner wall of the first installation hole 101 are filled with AB glue and then dried and cured. The inner wall of the first installation sleeve 2 is fixedly connected with the pins. 3. The pin 3 is a tooth spring pin, and the tooth spring pin is provided with at least 3 teeth, an...

Embodiment 3

[0060] Embodiment 3 is a further improvement to Embodiment 1.

[0061] Such as Figure 8 , 10 The inner wall of the shown seat housing 5 is movably connected with a drying structure 13 for drying. The drying structure 13 includes a desiccant 1301, a filling box 1302, an air hole 1303, an installation plug 1304, an installation jack 1305 and a placement groove 1306. The jack 1305 is opened on the inner wall of the seat housing 5, and the inner wall of the installation jack 1305 is plugged with an installation plug 1304, and the left end of the installation plug 1304 is fixedly connected with a filling box 1302, and the filling box 1302 is provided with a placement slot 1306, and the placement slot The bottom of 1306 is evenly and fixedly connected with air holes 1303, and the desiccant 1301 for drying is filled in the placement groove 1306, the drying structure 13 is arranged between the sleeves 8, the front side wall of the filling box 1302 and the groove inner wall of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com