Steel sheet and manufacturing method therefor

A manufacturing method and steel plate technology, applied in the direction of manufacturing tools, chemical instruments and methods, metal material coating technology, etc., can solve problems such as weld cracking, cracking, Zn intrusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

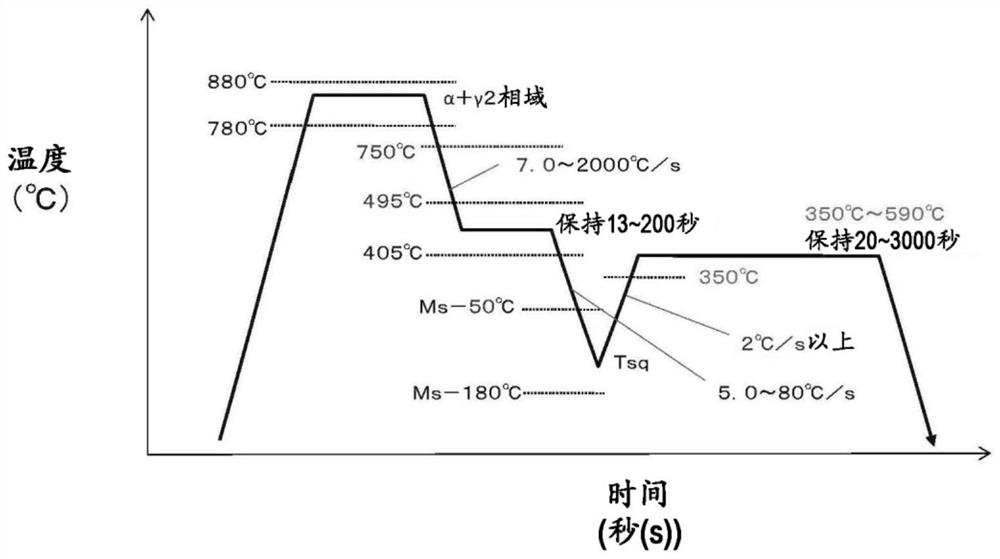

[0190] Steels having the composition shown in Table 1 were processed under the conditions shown in Table 2-1 to manufacture steel sheets of the present invention and steel sheets of Comparative Examples. The plate thickness of the steel plate was 1.4 mm. It should be noted that the conditions shown in Table 2-1 do not include zinc plating treatment.

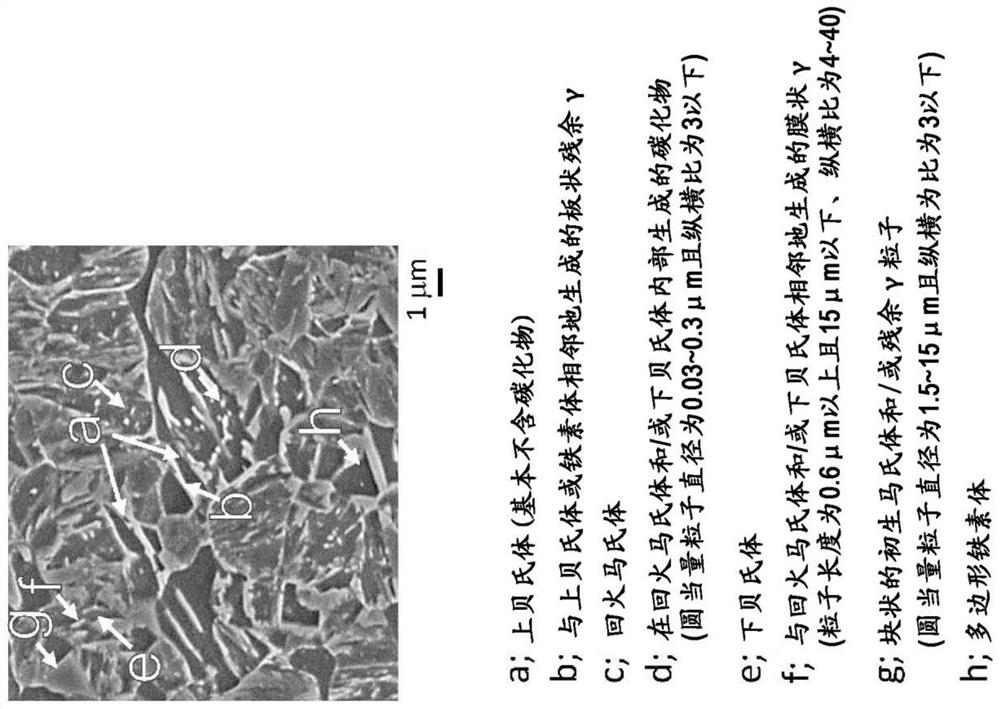

[0191] The steel structure was measured by the above-mentioned method. The measurement results are shown in Table 2-2.

[0192] JIS No. 5 tensile test pieces were collected from the produced steel sheets so that the direction perpendicular to the rolling direction became the tensile axis, and a tensile test was performed (based on JIS Z2241). TS and U.El are shown in Table 2-2.

[0193] In addition, the stretch flange formability was evaluated by a hole expansion test based on the Japan Iron and Steel Federation standard JFST1001. That is, after using a punching tool with a punch diameter of 10 mm and a die diameter of 10.3 m...

Embodiment 2

[0205] Cold-rolled steel sheets having the composition shown in Table 3 were treated under the annealing conditions shown in Table 4-1 to manufacture steel sheets of the present invention and steel sheets of comparative examples. The plate thickness of the steel plate was 1.4 mm.

[0206] In addition, some steel sheets (cold-rolled steel sheets) were further subjected to a hot-dip galvanizing treatment to obtain hot-dip galvanized steel sheets (GI). Here, the steel sheet is immersed in a zinc coating bath of 440° C. to 500° C. to perform hot-dip galvanizing treatment, and then, the amount of plating deposition is adjusted by gas wiping or the like. For the molten zinc plating, a zinc plating bath having an Al content of 0.10% or more and 0.22% or less is used. In addition, after the hot-dip galvanizing treatment, a part of the hot-dip galvanized steel sheet is subjected to an alloying treatment of galvanizing to obtain an alloyed hot-dip galvanized steel sheet (GA). Here, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plate thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com