A kind of ablation type anti-heat-insulation and wave-absorbing integrated composite material and preparation method thereof

A technology of composite materials and reinforced composite materials, which is applied in the field of ablation-type anti-heat insulation and wave-absorbing integrated composite materials and its preparation, can solve the difficulty of realizing the gradient distribution scheme of multi-layer electrical properties, the inability of thermal protection materials to have stealth functions, Affecting material mechanics and thermal insulation properties, etc., to achieve the effects of small electromagnetic parameters, reduced density and thermal conductivity, and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

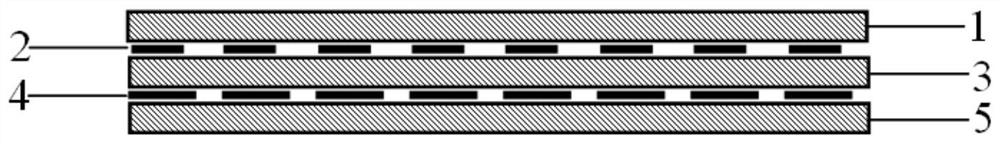

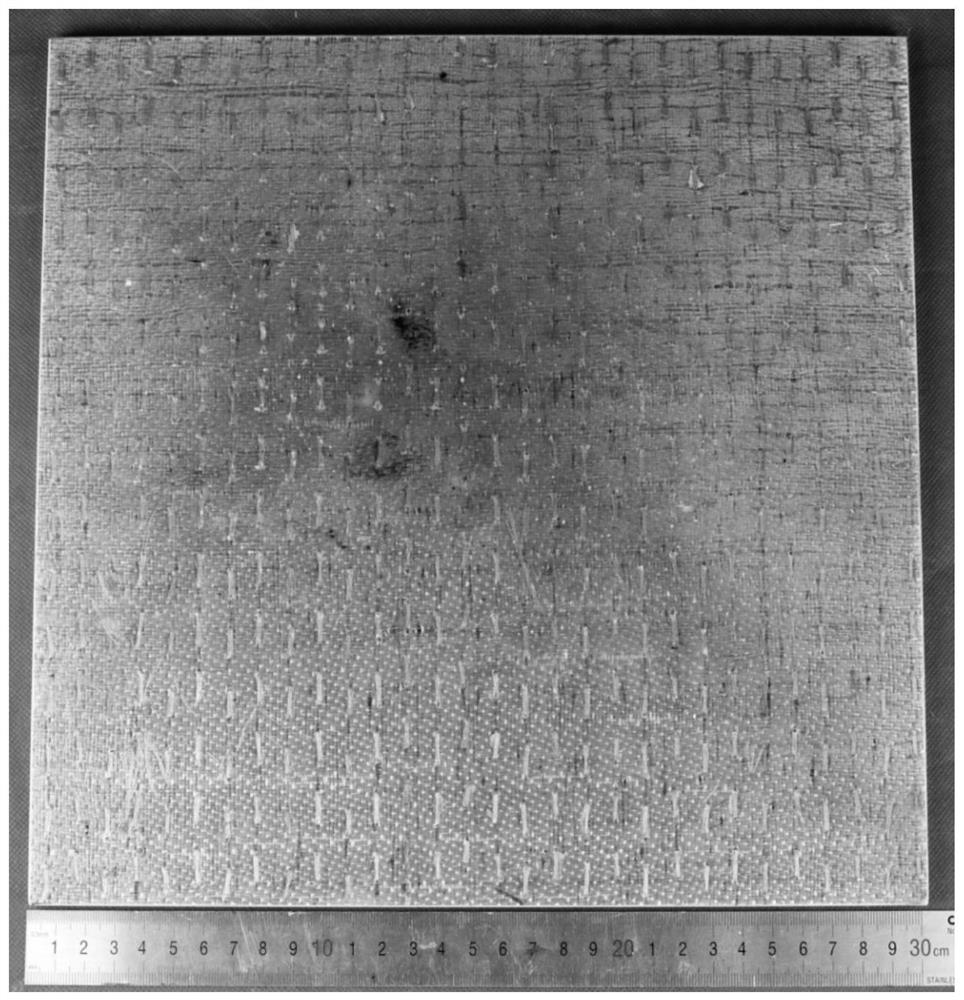

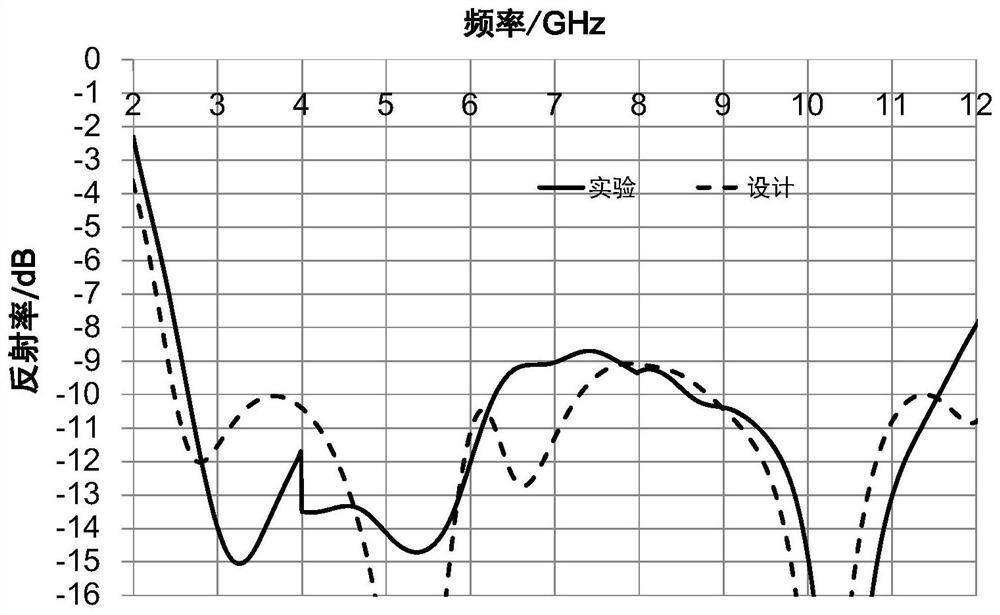

[0029] An ablative anti-heat-insulation and wave-absorbing integrated composite material such as figure 1 As shown, starting from the incident direction of the electromagnetic wave, it sequentially includes a first continuous fiber reinforced composite material medium layer 1 (thickness 5.2mm), a first lossy silicon carbide fiber array reinforced composite material layer 2, and a second continuous fiber reinforced composite material medium layer. 3 (thickness 1.7mm), second lossy silicon carbide fiber array reinforced composite material layer 4, third continuous fiber reinforced composite material medium layer 5 (thickness 2.6mm). Among them, the first, second and third continuous fiber-reinforced composite material medium layer reinforcements are two-dimensional quartz fiber fabrics; the first and second lossy silicon carbide fiber arrays reinforce the first and second lossy carbonization of the composite material layers The silicon fiber array is composed of two-dimensional ...

Embodiment 2

[0036] An ablative anti-heat-insulation and wave-absorbing integrated composite material, starting from the incident direction of electromagnetic waves, sequentially includes a first continuous fiber reinforced composite material medium layer (thickness 5.0mm), a first lossy silicon carbide fiber array reinforced composite material layer , the second continuous fiber reinforced composite material medium layer (thickness 1.9mm), the second lossy silicon carbide fiber array reinforced composite material layer, and the third continuous fiber reinforced composite material medium layer (thickness 2.5mm). Among them, the first, second and third continuous fiber reinforced composite material medium layer reinforcements are stitched quartz fiber fabrics; the first and second lossy silicon carbide fiber array reinforcement composite material layers of the first and second lossy silicon carbide The fiber array is composed of two-dimensional fiber cloth patch units arranged in a periodic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com