Preparation method and application of molybdenum carbide two-dimensional material

A two-dimensional material, molybdenum carbide technology, applied in the field of two-dimensional materials, can solve the problems of difficult control of the growth process and high growth temperature, and achieve the effects of stable controllability, easy operation, simple preparation process, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

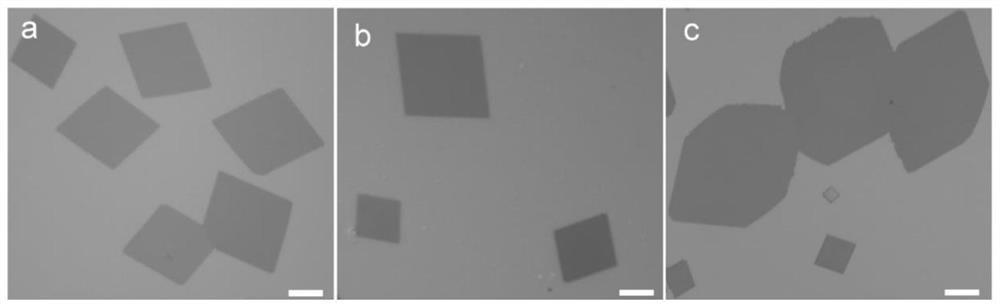

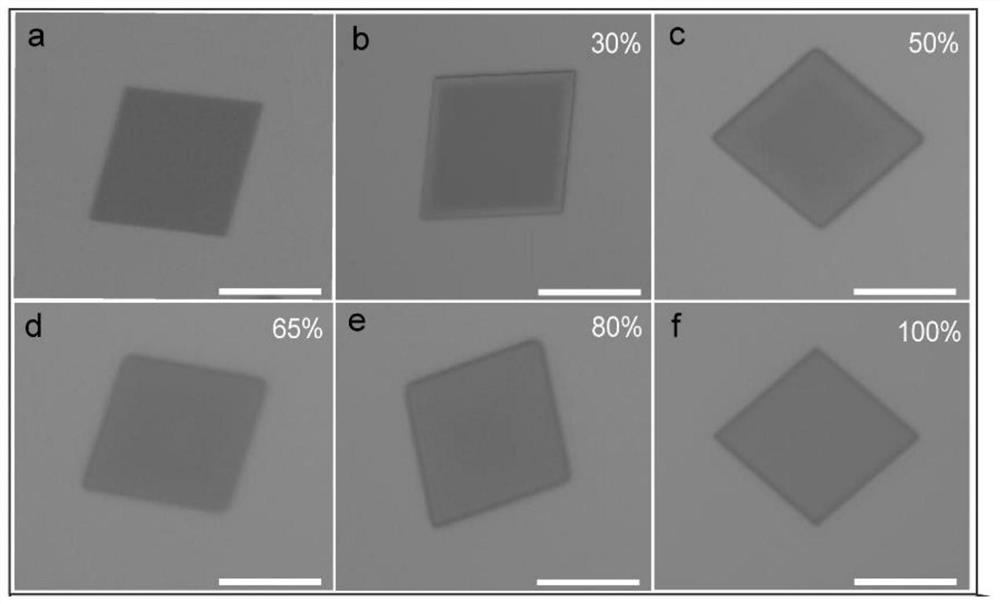

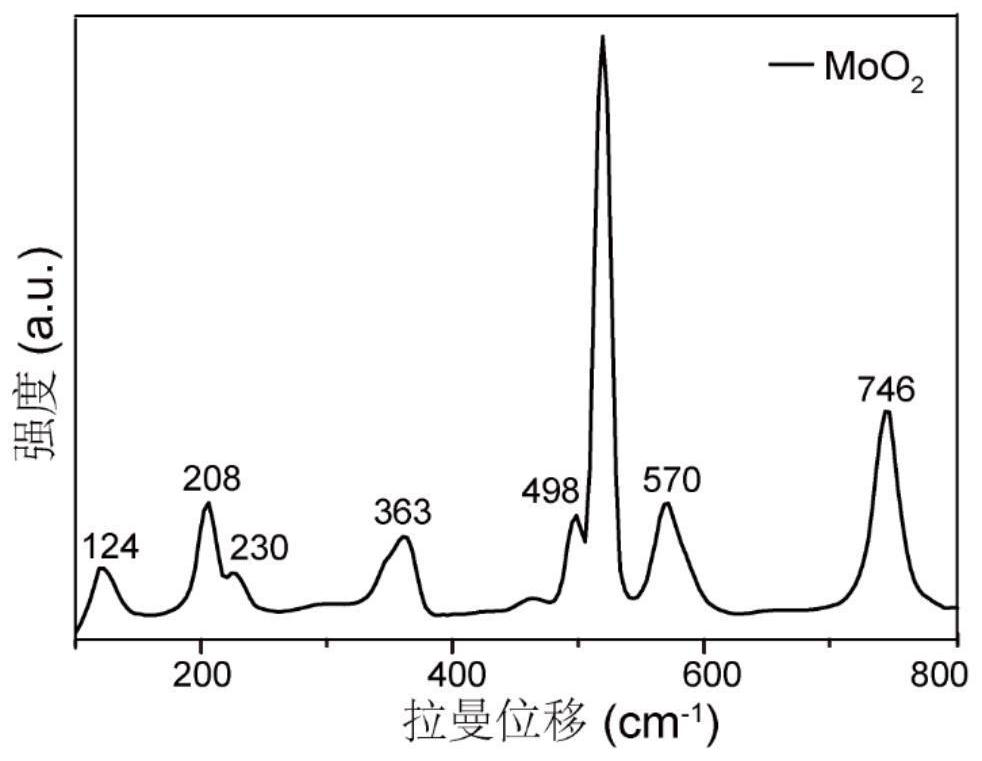

[0043] Step 1: Using a Chemical Vapor Deposition System to MoO 3 Powder (99.99%) was used as a precursor to synthesize MoO by thermal reduction reaction 2 Nano two-dimensional material, the material has the advantages of adjustable thickness, adjustable lateral size, high conductivity and so on.

[0044] The specific preparation method is: use chemical vapor deposition system to MoO 3 Powder (99.99%) as a precursor for the synthesis of 2D MoO 2 Flakes, 20mg high-purity MoO 3 powder into a magnetic boat, and the SiO 2 / Si substrate (thermal oxidation top layer is 260nmSiO 2 ) face down on the MoO 3 Powder on top. After pushing the magnetic boat into the center of the tube furnace and closing the tube furnace, feed high-purity Ar at a speed of 200 sccm for 30 minutes to ensure a stable oxygen-free environment in the furnace, then keep the Ar flow at 100 sccm, The furnace was heated to 790°C at a heating rate of 10°C / min, and kept for 5 minutes, and finally the system was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com