Conductive composite masterbatch for rubber cable shielding material and preparation method thereof

A rubber cable and shielding material technology, which is applied in the modification and application of carbon nanocomposite materials, can solve the problems of reducing the volume resistivity of shielding materials, difficult control of cleanliness, and poor tear resistance, so as to avoid the adsorption and covering effect, and the material Easy control of cleanliness and improved tear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

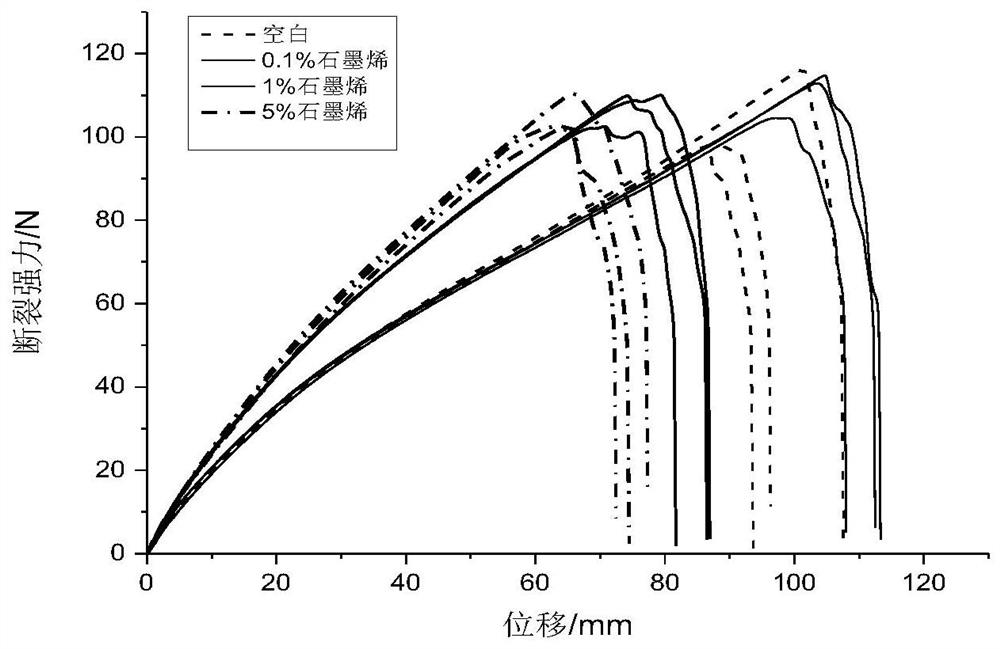

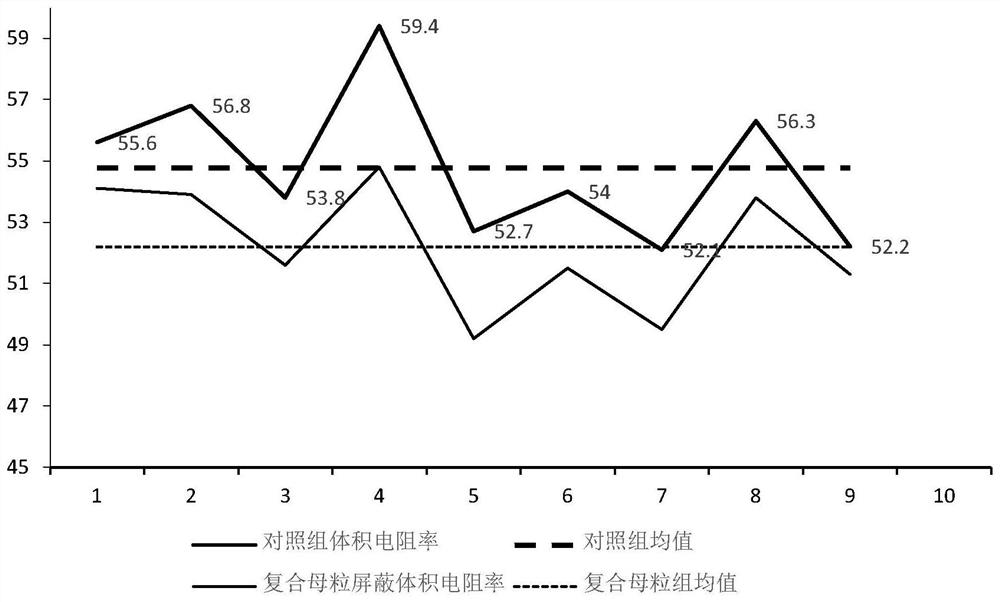

[0029]Embodiment 1: A conductive composite masterbatch for rubber cable shielding material, which is composed of the following components in parts by mass: 60 parts of colloidal graphene, 30 parts of superconducting carbon black combination, and 10 parts of paraffin oil. The colloidal graphene is composed of the following components: 0.1 part of graphene, 0.1 part of coupling agent, 0.3 part of dicumyl peroxide, 18.5 parts of pretreatment solution (12.34 parts of paraffin oil, 6.16 parts of diethylene glycol), 40 parts of liquid ethylene-propylene rubber. The effective content of conductive substances accounts for 30.1% of the total mass. The superconducting carbon black combination is composed of a specific surface area less than 90m 2 / g and superconducting carbon black A with a particle size greater than 40 nm and a specific surface area less than 100 m 2 / g and the superconducting carbon black B with a particle size of less than 20 nanometers is composed of a mass ratio ...

Embodiment 2

[0034] Embodiment 2: A conductive composite masterbatch for rubber cable shielding material, which is composed of the following components in parts by mass: 50 parts of colloidal graphene, 35 parts of superconducting carbon black combination, and 15 parts of paraffin oil. The colloidal graphene is made up of the following components: 0.8 part of graphene, 0.2 part of coupling agent, 0.22 part of dicumyl peroxide, 13.78 parts of pretreatment liquid (9.18 parts of paraffin oil, 4.6 parts of diethylene glycol), 35 parts of liquid ethylene-propylene rubber. The effective content of conductive substances accounted for 35.8% of the total mass. The superconducting carbon black combination is composed of a specific surface area less than 90m 2 / g and superconducting carbon black A with a particle size greater than 40 nm and a specific surface area less than 100 m 2 / g and the superconducting carbon black B with a particle size of less than 20 nanometers is composed of a mass ratio o...

Embodiment 3

[0039] Embodiment 3: A conductive composite masterbatch for rubber cable shielding material, which is composed of the following components in parts by mass: 40 parts of colloidal graphene, 40 parts of superconducting carbon black combination, and 20 parts of paraffin oil. The colloidal graphene is made up of the following components: 2 parts of graphene, 0.4 part of coupling agent, 0.2 part of dicumyl peroxide, 8 parts of pre-treatment solution (5.3 parts of paraffin oil, 2.7 parts of diethylene glycol), 29.4 parts of liquid ethylene-propylene rubber. The effective content of conductive substances accounts for 42% of the total mass. The superconducting carbon black combination is composed of a specific surface area less than 90m 2 / g and superconducting carbon black A with a particle size greater than 40 nm and a specific surface area less than 100 m 2 / g and the superconducting carbon black B with a particle size of less than 20 nanometers is composed of a mass ratio of 2:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com