Heavy metal contaminated soil remediation material, preparation method thereof and heavy metal contaminated soil remediation method

A technology of polluted soil and remediation materials, applied in heavy metal contaminated soil remediation materials and its preparation, and the field of remediation of heavy metal contaminated soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

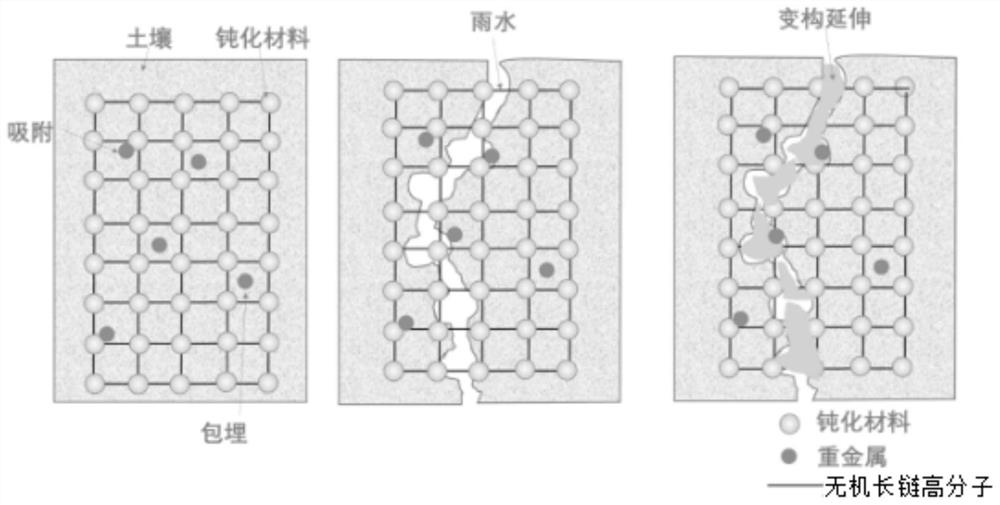

[0059] On the one hand, the present invention also provides a kind of preparation method of above-mentioned heavy metal polluted soil remediation material, and it comprises the following steps:

[0060] The Allosteric Extending Component, Deactivating Component and Long-Lasting Boosting Component are mixed.

[0061] In some embodiments, the method used to mix the allosteric extension component, the passivation component and the long-term promotion component includes but not limited to dry ball milling, ultrasonic dispersion, etc., and the mixing time is 30 minutes to 120 minutes.

[0062] In some embodiments, when the allosteric extension component is light-burned magnesite powder, before the step of mixing the allosteric extension component, the passivation component and the long-term promotion component, further comprising magnesite The ore powder is calcined at 800°C to 1050°C.

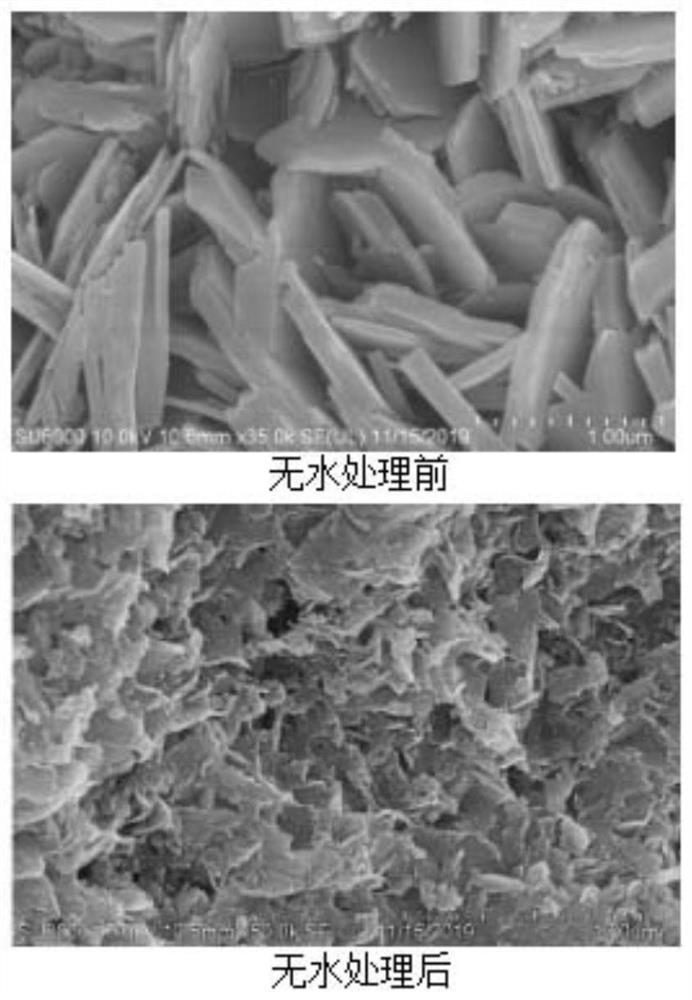

[0063] The main component of magnesite is MgCO 3 , mainly produces MgO after calcination. Di...

Embodiment 1

[0077] Preparation of Example 1 Heavy Metal Contaminated Soil Restoration Material

[0078] (1) Determination of calcination temperature of magnesite powder

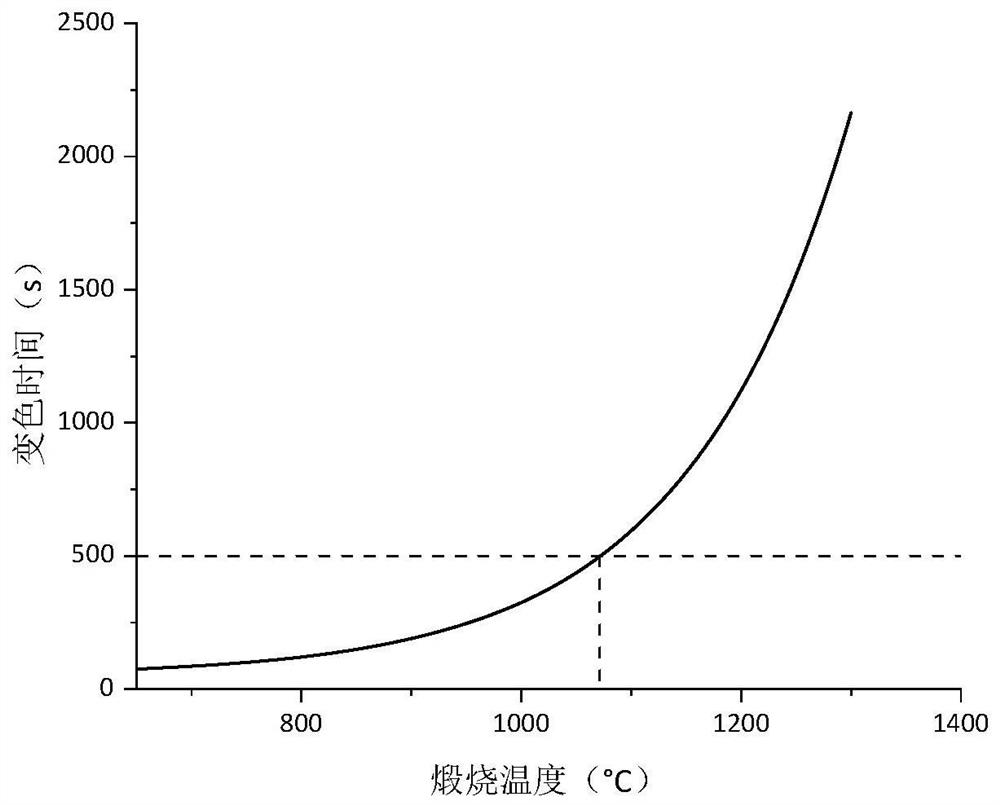

[0079] The activity of MgO, the calcined product of magnesite powder, was confirmed according to the titration method. The specific method is: take 1g of magnesite powder at different calcination temperatures and add them to 80ml, 0.25mol / L acetic acid solution, use phenolphthalein as indicator, and the time when the solution turns from colorless to red is used as the standard for judging the activity of MgO . Depend on figure 2 It can be seen that the activity of MgO has an exponential relationship with the calcination temperature, and the specific calcination temperature and the activity of MgO are shown in Table 1. It can be seen that when the time for the solution to change from colorless to red is less than 500s, the activity of MgO is higher.

[0080] Table 1 Calcination temperature of magnesite powder and rea...

Embodiment 2

[0091] The preparation method of Example 2 is basically the same as that of Example 1, except that the preparation method of the allosteric extension component is as follows:

[0092] Take the MgO calcined at 950°C and put it at 350°C, and pass it with N 2 Thermal activation treatment in a muffle furnace for 2 h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com