A kind of phenoxycarboxylic acid rare earth solution aluminum removal extractant

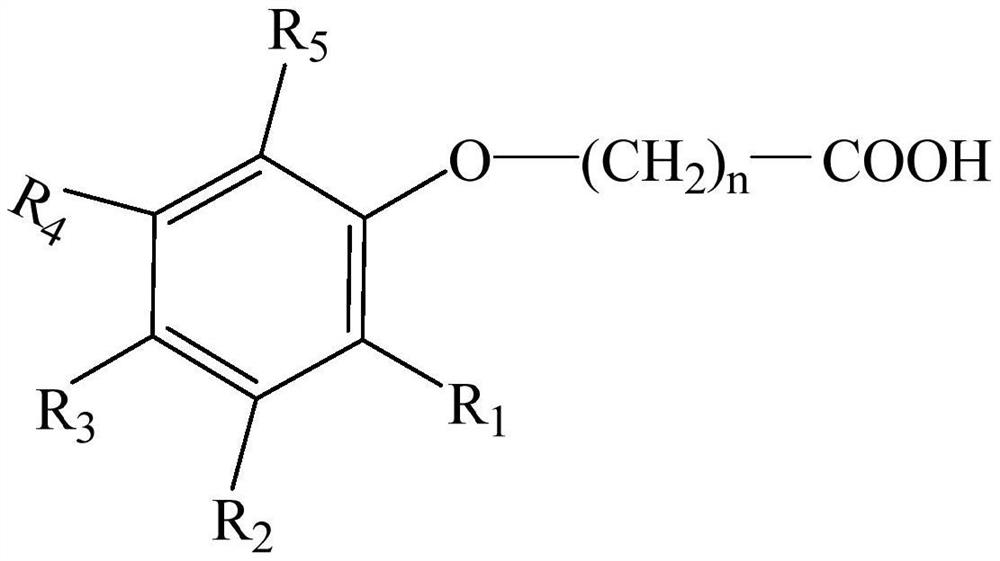

A technology of phenoxycarboxylic acid and rare earth solution, which is applied in the field of phenoxycarboxylic acid extractant and rare earth solution high-efficiency aluminum removal extractant. problem, to achieve the effect of stable extraction performance, less loss of extractant, and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

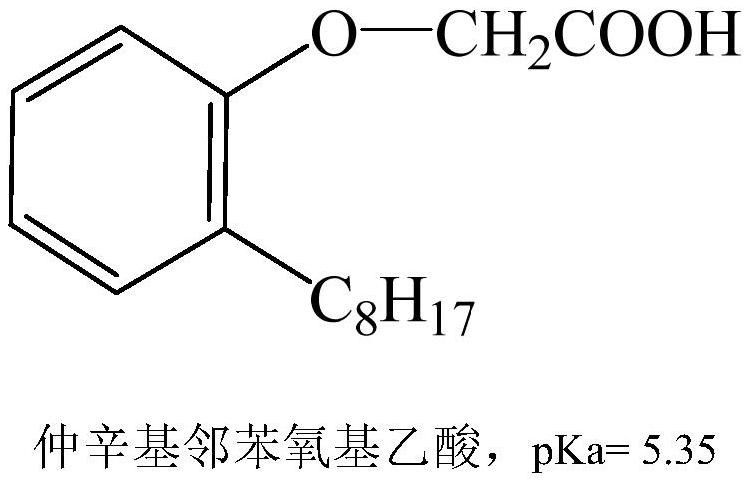

[0025] Second-octyl o-phenoxyacetic acid has a phenoxycarboxylic acid structure and a pKa value of 5.35. It is easily soluble in conventional organic solvents but hardly soluble in water. It can be used as an extractant for aluminum removal in rare earth solutions. Take 2.8761g of sec-octyl-o-phenoxyacetic acid (purity 92%, 0.01mol) into a 100mL volumetric flask, add sec-octyl alcohol and kerosene at a volume ratio of 1:3 to make a 0.1mol / L Aluminum extractant, add 50mL of 0.1mol / L NaOH solution, fully mix and saponify for 20min (saponification rate 50%). After standing to remove the water phase, take the saponification extractant 4mL and 2mL of AlCl 3 (0.01mol / L) and GdCl 3 (0.01mol / L) mixed solution (pH=3.5) was mixed at room temperature for 20min, left to stand for phase separation, and the aqueous phase analysis of the raffinate in the lower layer showed that the extraction rate of aluminum was 30.28%, the distribution ratio was 0.4344, and the extraction rate of gadolini...

Embodiment 2

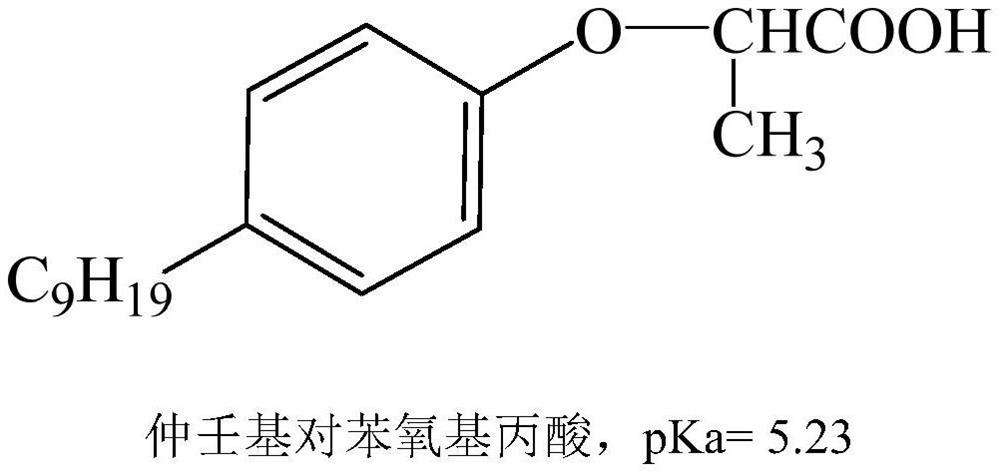

[0028] Sec-nonyl-p-phenoxypropionic acid has a phenoxycarboxylic acid structure and a pKa value of 5.23. It is easily soluble in conventional organic solvents but hardly soluble in water. It can be used as an extractant for aluminum removal in rare earth solutions. Take 3.1784g of sec-nonyl-p-phenoxy propionic acid (purity 92%, 0.01mol) into a 50mL volumetric flask, add isooctyl alcohol and toluene with a volume ratio of 2:10 to form a 0.2mol / L aluminum removal extraction agent, add 0.1mol / L NaOH solution 50mL, fully mix and saponify for 20min (saponification rate 50%). After standing to remove the water phase, take the saponification extractant 4mL and 4mL of AlCl 3 (0.01mol / L) and EuCl 3 (0.01mol / L) mixed solution (pH=3.5) was mixed at room temperature for 20min, left to stand for phase separation, and the aqueous phase of the raffinate in the lower layer was taken for analysis. The extraction rate of aluminum was 32.41%, the distribution ratio was 0.4795, and the extractio...

Embodiment 3

[0031]S-octyl-p-phenoxyacetic acid has a phenoxycarboxylic acid structure and a pKa value of 5.19. It is easily soluble in conventional organic solvents but hardly soluble in water. It can be used as an extractant for aluminum removal in rare earth solutions. Take 2.8735g of sec-octyl-p-phenoxyacetic acid (purity 92%, 0.01mol) to a 25mL volumetric flask, add TBP and n-heptane with a volume ratio of 3:10 to form a 0.4mol / L aluminum removal extractant , add 50mL of 0.1mol / L NaOH solution, fully mix and saponify for 20min (saponification rate 50%). After standing to remove the water phase, take the saponification extractant 4mL and 8mL of AlCl 3 (0.01mol / L) and GdCl 3 (0.01mol / L) mixed solution (pH=3.5) was mixed at room temperature for 20min, left to stand for phase separation, and the aqueous phase analysis of the raffinate in the lower layer showed that the extraction rate of aluminum was 35.32%, the distribution ratio was 0.5461, and the extraction rate of gadolinium was 0.5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com