Method for in-situ generation of diamond-like film precursor

A diamond-like film, in situ generation technology, applied in electrolytic organic production, metal material coating process, gaseous chemical plating, etc., can solve the problem of increasing the complexity of experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

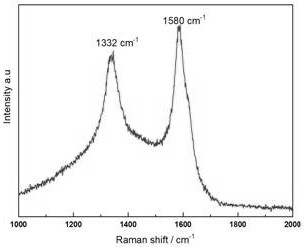

[0024] This example provides a method for in-situ generation of a carbon precursor and its subsequent use to prepare a diamond-like film, and the Raman spectrum of the sample is obtained as figure 1 shown. Substrate is a nickel base material in the present embodiment, and specific implementation steps are as follows:

[0025] (1) Weigh LiCl:KCl:CaCl 2 Molar ratio is the molten salt of 38.5:8.5:53, is placed in graphite crucible, in muffle furnace, 300 DEG C of drying more than 48 h removes the adsorption water in molten salt;

[0026] (2) Under the protective atmosphere of high-purity argon, heat the molten salt to 550 °C; after the temperature is stable, perform electrolysis;

[0027] (3) Cut to a certain length Φ 2 mm Ni wire, wound into a helical shape with a length of about 5 cm and a diameter of about 1 cm, which is used as a counter electrode;

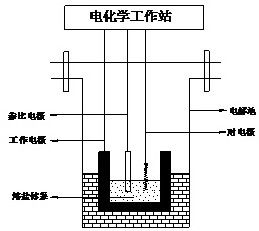

[0028] (4) In LiCl-KCl-CaCl 2 In the system, the working electrode is a graphite crucible, the counter electrode is a hel...

Embodiment 2

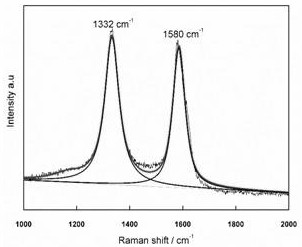

[0032] This example provides a method for in-situ generation of a carbon precursor and its subsequent use to prepare a diamond-like film to obtain a Raman spectrum of the sample such as figure 2 shown. Substrate is a nickel base material in the present embodiment, and specific implementation steps are as follows:

[0033] (1) Weigh LiCl:KCl:CaCl 2 Molar ratio is the molten salt of 38.5:8.5:53, is placed in graphite crucible, in muffle furnace, 300 DEG C of drying more than 48 h removes the adsorption water in molten salt;

[0034] (2) Under the protective atmosphere of high-purity argon, heat the molten salt to 550 °C; after the temperature is stable, perform electrolysis;

[0035] (3) Cut to a certain length Φ 2 mm Ni wire, wound into a helical shape with a length of about 5 cm and a diameter of about 1 cm, which is used as a counter electrode;

[0036] (4) In LiCl-KCl-CaCl 2 In the system, the working electrode is a graphite crucible, the counter electrode is a helica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com